Secondly and in the main, we’ll talk and try to do this today. We will start in detail.

Nano technology affected not only the production of cars, robots and spacecraft, but also slowly entered every home, in the form of household electronic new products. Not so long ago, such a concept as “smart home” appeared and it confidently entered into our everyday life.

American films often show a house that seems to live its own independent life. By light movement of the hand lights are lit. From the piercing gaze of the hero's movie, curtains or doors open. After the spoken code word, the music turns on ...

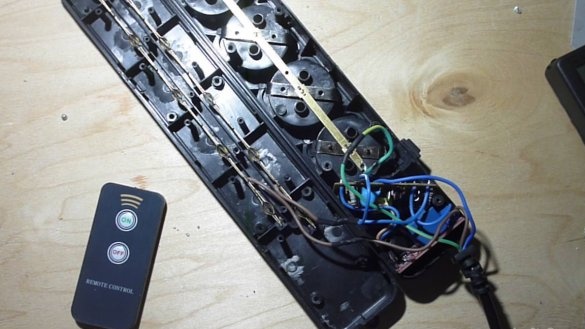

All this is the "smart home", that is, an intelligent electronic home control system. And today we will try to make the most simple device of this system. Namely, a "smart outlet." Which will be controlled through a remote control.

There are different types of control "smart sockets" - GSM, WI-FI, Infrared, etc. We will focus on the simplest version of a “smart socket” (we will not jump through the steps, we will start from the beginning, that is, the simplest one), namely, a socket controlled via an infrared signal transmitted remotely via the control panel.

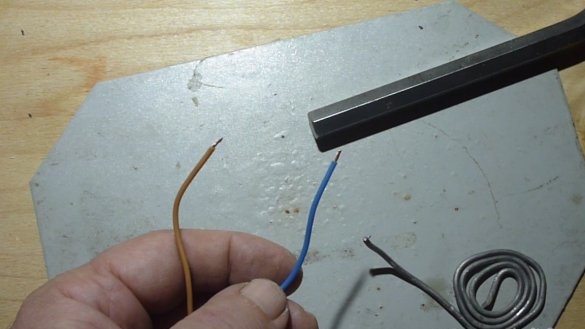

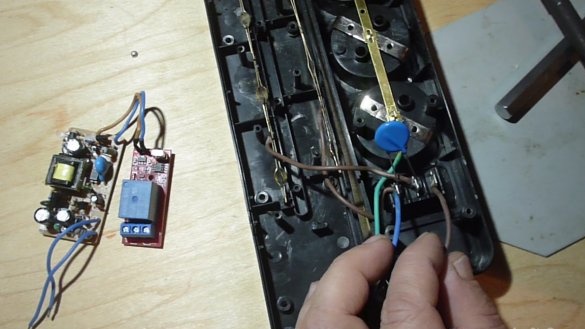

Two reasons inspired me to build this infrared “smart socket”. The main, absolute simplicity of manufacturing (read - accessible to everyone, or almost everyone). Second, the availability and low cost of components (for the manufacture of the device I purchased only an infrared remote control unit for 180 rubles (such a “smart outlet in the store costs about 2,000 rubles, including a decent amount of money)” on Aliexpress, a link to whom it’s interesting - 1 channel relay module for electronic devices .

I found the rest in the garage and dusty corners of the apartment. By the way, on Aliexpress I also ordered a smart soldering iron for 60 watts., With manual adjustment of the tip temperature and electronic indication, a link to the soldering iron - 60 W / 80 W Adjustable Temperature Electric Soldering Iron, and to brag to the end, I ordered there, the so-called "third hand", for soldering, device for fixing the circuit board, a common problem when soldering is missing one hand, in order for everything to be well soldered, a link to the "third hand" - Soldering iron stand “third hand”, magnifying glass, 2 crocodile clips, rotating 360 degrees)

Quite a bit about your health. The voltage of 220 volts is dangerous for your health and life! Today we will have to work with this voltage. Be careful not to measure it with your fingers, and even more so with the gentle pulp of your tongue. Please follow the safety precautions when working with electricity, other hazardous appliances and equipment. If you are serious about these rules, then to a very old age you will walk with a wide smile on your face, stepping on the ground with two legs ... :-)

So, let's begin.

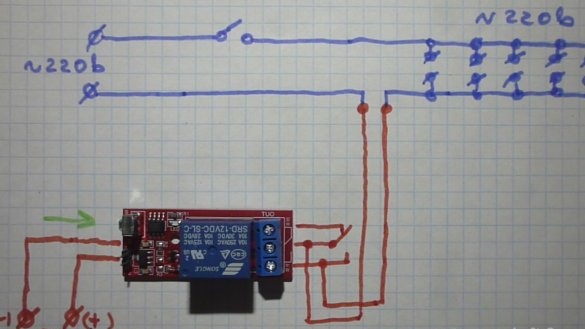

The principle of operation of the infrared remote control unit is as follows: We have a remote control transmitter of infrared radiation, the declared range of 8 meters, is enough for a city apartment. The transmitter delivers an infrared signal to the receiver executing unit, an infrared sensor is installed in the unit, which also receives, through the electronic system, converts the signal into an electric voltage sufficient to turn on the executing relay. When the relay is turned on, the working contacts are closed, which include the necessary module in our case, through a closed relay contact, the supply voltage is supplied to the socket block, a voltage appears on the socket block. A smart socket has applied voltage to a consumer, such as a lamp.

Possible applications of our device homemade:

Turning the lights on and off, radio points, rebooting the router, heating appliances, turning the aquarium appliances on and off, turning on and off watering indoor plants (you can use them at the dacha too, but the scale there is different) and much more (good thoughts always come in time for you too , an interesting idea for using this device will probably come to mind).

To those who like to watch home-made eyes with their eyes, rather than reading, I present a video clip instruction that details the process of manufacturing a “smart socket”.