Stages of making a casket:

- The main types of products

- Necessary equipment

- Materials for making papier-mâché

- Winding and gluing blanks of the body

- Pressure testing and drying

- Workpiece boiling

- Filing

- Hardware fittings

- Casket decarning

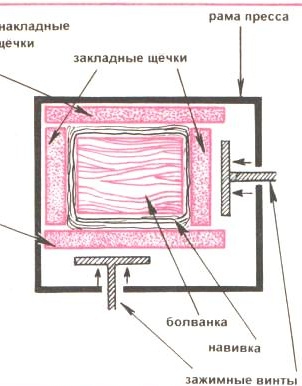

1. Corner press. Its frame can be welded metal or wooden. It is important that the press can provide two-sided crimping along the centers of the faces of the workpiece (see Fig. 3).

2. Joiner clamps, preferably with an adjustable grip length.

3. A rubber bandage, a tourniquet, or a strip of a 20–30 mm auto-camera.

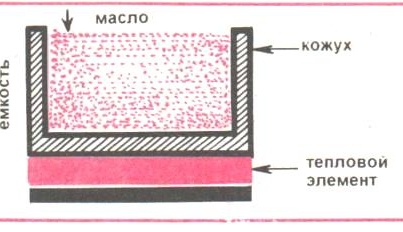

4. A device for boiling dry billets in a boiling drying oil. The tank must be mounted with an electric stove in a frame with a covering casing, making it impossible to spray oil onto the thermocouple (Fig. 4).

5. An oven in which a constant temperature of 80 ° C can be maintained. About him in more detail in the issue of "Do it yourself"No. 2 for 1996.

6. Joiner's workbench or devicereplacing it.

7. "Doodles" wooden (preferably birch). The bars are harvested with a section corresponding to the inner perimeter of the future product. All surfaces must be cleaned and oiled from the ends and planes.

8. Lathe for finishing round products.

9. Bench vice for the manufacture of products and accessories.

10. The minimum set of carpentry and locksmith tools.