1. Steady unicycle wheelbarrow.

3. "Handwheel" drill.

Handwheel drill.

Chinese bone and stone carvers have always been famous for their openwork products, which required many holes to be drilled in them. How did they manage to avoid the appearance of numerous chips in fragile materials such as stone and bone? For example, try to drill a neat hole in a tubular bone or in a faience sink with a conventional hand drill. Well, if at least half of the holes would be without chips. But the Chinese masters did not have a marriage. It turns out that they used mainly a “flywheel” drill to make holes, as well as feather or tubular drills and fluids with additives of surface-active substances (surfactants). Handwheel drills can still be seen in optical workshops, where spectacle lenses are attached to the Pat frames, through holes drilled in glass.

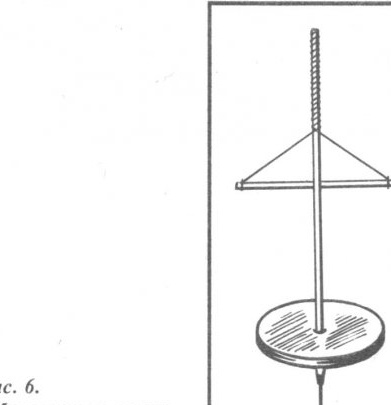

Now about the device "flywheel" drill (Fig. 6). A thin feather drill is fixed (with a standard collet clamp or simply “tightly” in a socket of the corresponding diameter) at the end of the shaft 30 ... 45 cm long and 1 ... 1.5 cm thick. A flywheel is cylindrical in shape not far from the drill. The latter is usually turned on a lathe by order, but I have successfully used the flywheel from a broken old reel tape recorder - this flywheel is very precisely made and well balanced. Two flexible strong cords are fastened to the upper end of the central rod, the opposite ends of which are tied to the ends of the bar 15 ... 25 cm long.

Using such a “flywheel” drill is easy. You can drill even with one hand (which is not possible with our mechanical drills with a gear drive). To bring the drill into rotation, both cords with tension are wound on the central rod, while the crossbar is lifted. Then everything is simple: put the drill in the place where it is planned to make a hole, click on the crossbar, the cords are unwound, bringing the drill with the flywheel into rotation.After 1 .. .3 s, the untwisted flywheel winds the cords on the rod again, but in the opposite direction. This should not be prevented, since our drill does not care where to turn. Just let the bar run up again, then press it again.

Of course, only feather and tubular drills are suitable for a “flywheel” drill (in particular, holes with a diameter of about 2 mm can be drilled ... with writing tubular assemblies from ballpoint pens made of a copper alloy; granite, quartz, porcelain, glass lend themselves to such a drill )

Drilling holes in solid materials with copper drills, for example, tubular, was mastered in ancient Egypt about 4 thousand years ago. Europeans repeated this discovery only in the 14 ... 15th centuries. In order to successfully form holes using a copper drill, liquid and crushed abrasive are supplied to the drill. The viscous metal of the drill as a result captures individual grains of abrasive, and already these grains cut the material. Well, what is the role of fluid? It is clear that the fluid is designed to both cool the drill and remove chips and sawdust from the drilling site ... But why did the ancient masters use not just water, but solutions of surface-active substances when drilling (Egyptian artisans - beer, Chinese craftsmen - decoctions of certain plants) ?

The fact is that water and other liquids, especially with the addition of surfactants, significantly accelerate the growth of cracks during cutting of materials, and in fact facilitate cutting. In the 20th century, this effect was explained in the works of Academician P. Rebinder (I think most readers as a child noticed that crushing a dry piece of sugar is much more difficult than a piece of wet). By the way, the Rebinder effect is also useful when drilling brick or concrete walls with carbide drills, if there is no hammer drill. Things will go much faster if the pear-douche (or an old large syringe) periodically feed water with a small amount of washing powder into the drilled nest. And as soon as the material and dust from the drilling are dry, the drill is removed from the hole and a little water and powder are added to the latter again. The drilling speed as a result increases by 2 ... 3 times.