Content:

2. Living thread of times

3. And patience is longer than the thread itself

Living thread of the times

Spinning did not become a miracle of the world simply because, perhaps, there was nothing to compare with - there were no other miracles that have become famous for all centuries. But people sacredly believed that the art of turning fibers into threads is a divine gift. The Egyptians believed that the insane Isis taught them to spin, the Chinese gave this honor to Yao, the wife of the emperor of the Celestial Empire, the Lydians - Arachne, the Greeks - Minerva, the Peruvians - Mame oella, the wife of Monte Capaco, their first sovereign. In Russia, the half-Slavic-half-goddess goddess Mokosh turned out to be a mentor to women, and Prince Vladimir Svyatoslavovich introduced her to the pantheon of pagan idols. The girl spins, and God gives her a thread.

Twisting woolen hair into yarn, an ancient person most likely unconsciously repeated what was observed in nature. In the tiny river snail, in the funnel of the whirlpool, in the arrangement of leaves on the stem, in the flight of birds and in many other phenomena of the world, one and the same form occurs - spirals, corkscrews. The similarity of spiral formations, as it turned out, can be seen no less than in vortices and tornadoes. Spiral, astrophysicists have established, the sleeves of galaxies are twisted, many star systems. And other than a spiral, a helix. Opening it, Archimedes used a screw to extract water. In modern machines, devices, appliances, household appliances, screw thread plays the role of fasteners, acts by the force of the press, creates rowing and air traction, moves the undercarriage of the machines, and in the bobbin and spinning machines - screws.

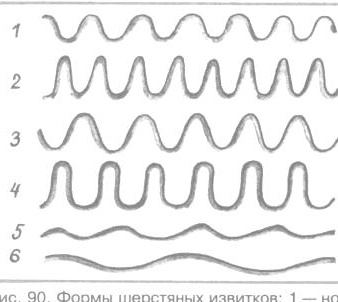

Spirals also wriggle in a high quality rune. Against straightened, slightly curved, crimped are more tenacious (Fig. 90). In fine-fiber wool there are up to 10 twists per 1 cm of hair. From rotation in convoluted wave-like strands, the number of weaves increases, the hairs lie in a spiral, which adds strength to the yarn.

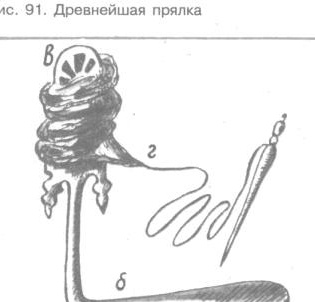

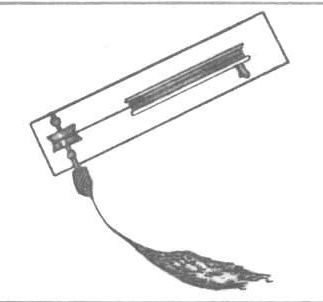

Manually braid the fibers with a corkscrew using a spindle and a simple device - a spinning wheel. The spindle — in the general sense, the axis on which something rotates — underwent significant changes in spinning over time - from a wheel and a simple rod in girlhood to an elongated cone 20-40 cm long. By the way, just under the name "rod" it appears in the literature of previous centuries. The spinning wheel also changed.But the simplest survived the more developed descendants, apparently, due to the fact that the familiar is always more understandable. After all, any new device is usually perceived for a long time with prejudice: from one end it is cunning, from the other it is more sophisticated, and in the middle the mind goes beyond the mind. The original structure coexists with others also because there are no problems with it either in work or in manufacturing, even if a person took up tools for the first time in his life (Fig. 91).

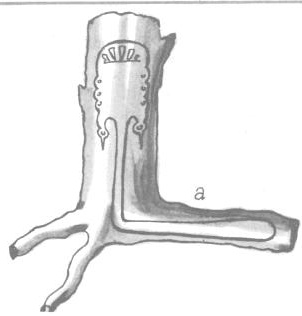

A tree with stronger wood is selected, say spruce. It is necessary that she (Fig. 92) has one of the secondary roots a growing at right angles to the trunk. Cut the tree in height, what a spinning wheel needs. Cut off all the roots except the transverse. The stump is trimmed and the root too. A board is gradually made from a stump, making it to the size of a future spinning wheel, as it is depicted inside the trunk. For this, the stump diameter is required at least 27 cm.

Part b (Fig. 91), cut down from the root, is called a hoof. A woman sits on it on a bench when she begins to spin. The wide part in, resembling a shovel, is a blade. Often, nicks are made at the edges of it, on which fluffy, combed layers of wool are fastened, folded into a loose tube. Sometimes the blade ends with a fork (horns), a crescent or some kind of stand (bottom). The tow is leaned against and pulled together quite tightly with a leather bandage (cover), which is dismembered by a stick (dog). All this moves as the tow scroll empties.

A short, non-waxed darning-type thread is attached to the thin end of the spindle. Sitting on a hoof, somewhat sideways to the blade, a woman from the middle of the tow with her left hand begins to stretch first a small bundle of fibers, which, as it were twisted, envelops the darn. Then attaches the end of the tow to it - with the thumb and middle fingers of the right hand rotates the spindle to the right. On the spindle they put the load in the form of a circle - a presale.

The first few tens of centimeters of thread are wound on a spindle closer to the heel, its thick end. Further, the spin again forms a thread, placing the fibers along, bundle after bundle, for the length of the arm. One fiber should grab the edge of the other, the second - at the end twists of the next, then a reliable, worn yarn is formed. All this time, a woman with her left hand pulls the tow bar of her tow. Since unwashed hair is more obedient, one has to endure some inconvenience - an oily sticky mass of hair settles on the fingers. Spider constantly spits on his fingers to twist the thread better. The author of the French manual on spinning, published at the end of the XVIII century, especially hopes that unwashed wool "can be brought to a high degree of fineness by means of fatty substances"; after cleaning, the thread is round, strong, decent for use on fabric of excellent goodness.

Taking the thread away from himself, spinning, as for the first time, rotates the spindle and with his right hand wraps the finished thread on it with a cone, throws the end over the top with a loop. Exceptionally appreciated is the so-called balance of twist - rhythmically repeating spiral curls. To do this, the spiner winds the entire thread hand-wound on the spindle, because the remaining end after the second twist will be dry and break-chat. She also does not allow non-spinning, so that part of the still non-poisonous thread falls on the spindle. Clearly, both errors will show themselves in the product.

The free part of the thread between the barb and the spindle is called fathom. Once in a while, fathom after fathom yarn arrives, on the heel side weights the spindle. It seems that twisting it becomes more agile. The full thread of the spindle is called a blanket. The hand will feel by weight that it is time to translate the spun into a ball or remove the whole cone of wound yarn, wrapping it with paper.

Twisted yarn is not considered to be a thread, it is spoken of by a word of the middle kind - spinning. This is roving, severity, semi-finished product, live thread. If the wool is spun to knit, the thread is doubled, reed, weaved two into one, turning the spindle to the left. On products soft, fluffy, which knit on knitting needles, a tight twist is not required.But one and a half times denser they reduce spiral rings in yarn intended for a hook.

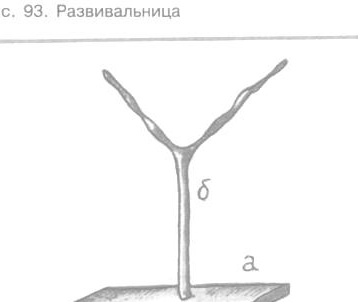

According to the centuries-old rules, it is supposed to transfer from the spindle to the unspun spinning into skeins with the help of a development tool, reel, reel (Fig. 93). In the plate a (horn), a viburnum branch b with two spread processes is inserted. Holding the horn in his hand, the spinner winds yarn on it so that the threads lie between the processes and cover the horn. The yarn removed from the reel is poured, put in wet ash, and then bleached on snow (for more details on processing spun yarn, see the next chapter.)

From this moment, the paths of the skeins diverge. Some put off for knitting, with the remaining work still to be done. When they mean to get yarn on textile, they especially look at which thread is worthy to be the basis, and which will be ducks. The general rule is that the length of the fibers, their strength and strength, the base always exceeds weft bobbins. That is the basis. But all this is determined even when sorting raw wool.

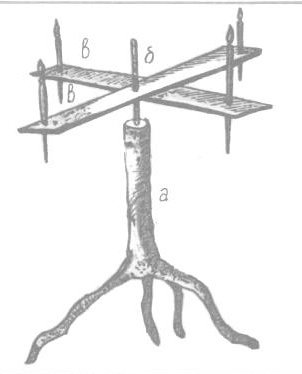

The yarn is not doubled on the fabric, a single-strand thread is put on sparrows (Fig. 94) and braided. The stand a (view) is nothing but a young pine dug with roots. The roots serve as legs for the instrument. An iron nail b is hammered into the top, and the sparrows themselves are thrown onto it - pine bunches folded at right angles to, at the ends of which holes for spindles are checked. Sparrows revolve around a nail. At the edges of the sparrow spindles form right angles. On their perimeter and wrap yarn.

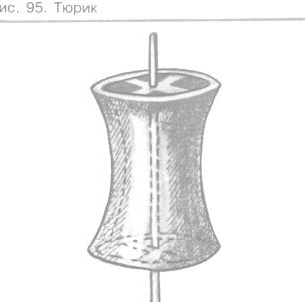

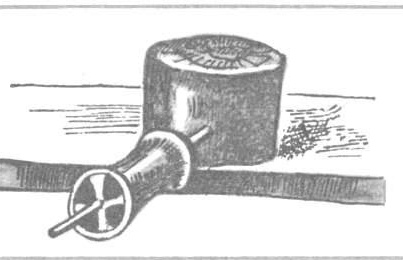

The next operation is the rewinding of yarn on the reels-guriks. The aspen block is hollowed out inside and cut off from the outside (Fig. 95). The length of the turik is not less than 70 cm with a diameter of 27 cm. The top and bottom of the turik are crosswise closed by birch bars, in the center of which holes are drilled. And a birch spoke is inserted through them through the height of the turik - the axis of rotation of this entire coil. The axis is hammered into the block. The block is set on the bench (Fig. 96). The job is that while spinning, sitting at the deck, with one hand holds the thread with a sparrow, and the other rotates the turik. Of course, there are more than one such Turik on the farm.

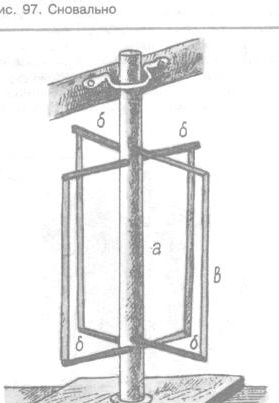

Finally, from the Türks, the threads fall on again (Fig. 97). For him, they take a place in the barn or povet, in another room where the wool is processed. A pine pillar a and a half meters long and above the bottom is installed in the board so that it can freely turn around in the nest. The upper end of this rod goes into the bracket nailed to the sledge. Criss-cross bars are used to cross the post, the ends connected by small columns into the main pillar serve as the axis of rotation of everything again. Again, the yarn is rewound onto a warp, and that is inserted into the bed - a loom.

A smooth, even twist thread, as practitioners know, is universal. But such yarn, no matter how you mess, you won’t get when you have short fibers at your disposal. Straighten, of course, and from them. But the craftswomen insure that they knit this pure-woolen thread with a second, cotton or some kind of synthetic. With a relatively short coat, there is always the temptation of a string. Wool steeper than usual so that the yarn comes out less “bite” and the ends of the fibers do not come out faster than expected to be wound onto a simple, non-factory impregnated, non-mercerized thread. A spinning thread is inevitable if very weak or completely unkempt wool is handled. As a rule, rabbit fluff is harnessed to the cotton base, it is difficult to work with it differently, moreover, none of these threads counts on durable things.

If to ordinary home artificial or little-known fibers are knitted by the wool, you can hardly guess how both materials will behave in the product. Therefore, spinning an independent thread from additives is less risk.

In the frosty Russian regions, yarn threads prefer the so-called fluffy. Unplaned tufts of wool are grafted at one end with ordinary wool (by the way, short fibers will also go here) or they are simply knitted. One way or another, it turns out clothes in which you will not frostbite in the most terrible cold.Mittens and socks, lined with wool from the inside, for children in winter - salvation. The mittens do not get wet for a long time and you can, sometimes, go sledding until late until you hear the icy floors of your clothes. For adults, waistcoats were knitted in the same way, light, keeping warm, wherever a person was - at a logging site, in an open field, on a long car trip or swimming.

The idea of fluffy, unfortunately, degenerates into a market way. On any quality, the core base is slightly wound, if only expensive and rare fibers, the same Angora, are kept. Moreover, one end remains loose, walks by itself. If according to the finished thing, having sprinkled with water well, they zealously walk with a metal brush, fluff or other fiber will rise and close the knitted rows. An inexperienced buyer is now worth nothing.

When in the hands of just a kilogram or two of wool, it may not make sense to venture with the manufacture of the spinning wheel, although it is as simple as described above. It is enough to strengthen a bunch of wool and take up the spindle. And rewinding will take place perfectly on the backs of two chairs, set one against the other, or quite primitive - on the assistant's hands half-extended and bent at the elbow. As the saying goes, there would be a tow, we’ll do a spindle, and we will borrow on the bottom.

The spinning workflow has not changed since antiquity. Only then only slaves were spun. For a day they were given a certain amount of raw materials. Sitting or standing, they ensured that the balls of wool were wound evenly, denser or weaker, as ordered, so that in each ball of yarn the yarn was of the same quality - smooth or fleecy. Nodules on the thread were bitten off with teeth. It is known that the Greeks used epinestrone, which was invented five centuries BC, to draw wool fiber. There is no doubt that the manufacture of yarn remained a tedious task. Otherwise, why would Hercules (Hercules), legend has it, be punished with nothing more than sold as a slave to Omphale, the imperious queen of the Asia Minor state Lydia. Dressed in a woman’s dress, he spun for two years with her slaves.

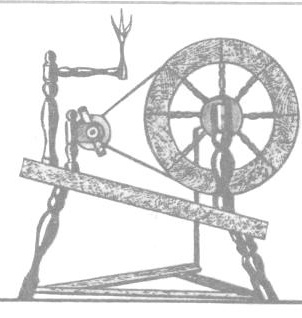

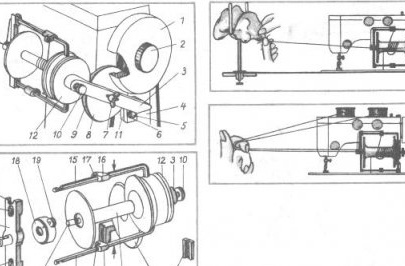

The principle of a spiral, a vortex, a top is preserved in the designs of spinning wheels, no matter how they are perfected over the centuries (Fig. 98). This type of spinning wheel according to the documents is attributed to the year 520 of the current year. A wheel was fixed on the board, which set in motion a block firmly mounted on the spindle, and through it the spindle itself. It took mankind two thousand seven hundred years to create a hand-made spinning wheel in the form as it is known today (Fig. 99) under the name of a small spinning wheel. According to reliable evidence, by 1200 village craftsmen made similar devices, and in the 14th century they also used manual spinning wheels in large cities in Russia.

In England, France, Germany, Holland, our spinning wheels differed mainly in wheel diameter and spindle thickness, as well as in the arrangement of the spinning board - horizontal or vertical. The smaller the circumference of the wheel and the thicker the spindle with other constant values, the less steep the yarn was. At the same time, a rule developed: twist the wool from left to right and from three turns of the wheel, and the weft from right to left, stopping rotation after the second round.

As explained in the past, the accuracy and uniformity of the material being produced (expendable wool. —NB), uniformity and the proper number of circulations at a certain time gave the spinning wheel of such parameters. A horizontal bench or board, 600 mm long, is approved on three or four legs 330–355 mm high. A wheel with a handle in diameter reaches 580-610, and even better - 635 mm. The circumference is thin, like a large sieve, with a width of 760-820 mm.

Spinning went quicker with two handles and argued even more when the wheel began to be launched with a foot. Allegedly hired foreign soldiers brought the self-spinning wheel to Europe, and the Berliners were the first to teach this method. However, the spins of the freed hand were immediately asked to work in British workshops.Spinners were seated in a circle, each pulled two strands at once, while a ten-year-old child turned four wheels with blocks and ropes, moving up to two hundred spindles evenly, smoothly and relatively quietly.

At that time, the knights had already degenerated into traders, arenas turned into exchanges. Greed recruited new volunteers, or, as they used to say, prolase. Due to the general interest in technical innovations in spinning, this little-respected public warmed their hands at the expense of the ever-begging inventors and fooling the state treasury officials.

To help compatriots, assessor of the Russian State Manufactory College Sazonovich in 1798 was instructed to prepare a book on spinning methods and self-spinning devices in European countries. He made a comparison and showed that Russian designs are not inferior to any other. And today in the Arkhangelsk museums you can see an inimitable collection of self-spinning wheels of the Russian North. Each is not only a true work of art. It is convenient and functional (in detail the manufacturing technology of such a self-spinning wheel is shown in the fourth issue “Do it yourself"For 1995.)

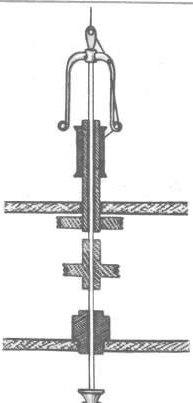

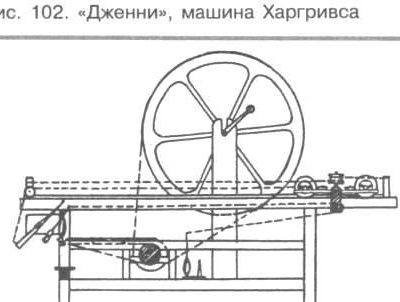

Meanwhile, spinning was still handmade. How to facilitate it, thought for a long time. Even Leonardo da Vinci makes brilliant guesses by sketching in notebooks drawings and calculations of a loom, spinning wheels. In 1452, he carried out one of the ideas, created the first and perfect winding mechanism, which subsequently began to be used in flywater (Fig. 100). But his device remained unknown for a long time. And the design idea wandered for some reason mainly around the spindle. The German Jurgens in 1530 constructed a spinning wheel with a fly spindle. The knitted thread was wound in sections, Jurgens applied to the flyer division (Fig. 101). Then a flyer spindle with a snail type gear was born, spinning designs with an exhaust hood, positive hood. But such a weak link as the mechanical supply of the roving to the spindle did not fall into the field of view of the creators of the machines. And for a long time tried on to ensure that the spinning to connect mechanical force. Autumn, as they say, the Englishman Hargreaves, when he watched the work of his daughter on a spinning wheel. He set the spindle vertically, and not one, but 16. He arranged the transfer to them from the drum through the cords, and the spinner started the machine by turning the handle. The author named his car “Jenny” in honor of his daughter (Fig. 102). In the future, the number of spindles was increased, as the discs are hung on the bar. In the end, there were 80 of them. One man could not cope physically with the big one. Nevertheless, the fact remained that the machine was spinning, it was doing the work that human fingers used to do.

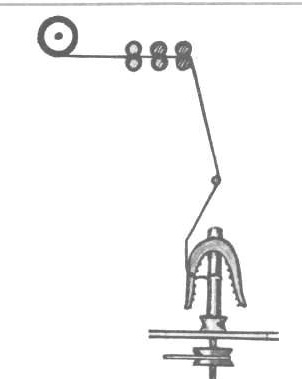

Further into the story is a crime plot. Someone Arkrayt, a hairdresser, as if using the exhaust rollers for curling wigs, used the device in spinning (Fig. 103). In fact, he stole another's invention of the improved Jenny and launched the case, not without reason, in a hurry, until it was exposed. The movement of the car was supposed to come from a water wheel. The barber built a factory on the banks of the river, installed water machines there, hired 600 workers, and became fabulously wealthy before they brought him to clean water and lost his patent.

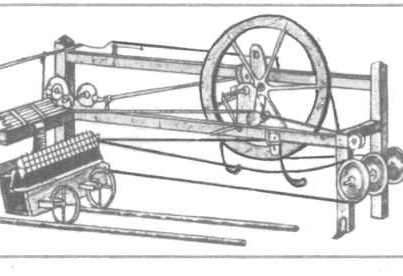

"Jenny" gave a thin, but fragile thread, from the water machine the yarn came out, though strong, but very rough. Combining the virtues of both predecessors, the inventor Crompton pored over his offspring “Mul-Jenny” for more than two decades (“mule” means mule). Eight spindles (Fig. 104) Crompton installed in the carriage movable so that the spun yarn received an extract, and this did not cause much stress in it. However, in the samples, the yarn still looked uneven and weak due to the fact that it was twisted without sufficient clamping and pulling. Then, to the pair of rollers that grabbed the roving, Crompton added an additional pair - pulling the thread. In the technical literature, Mul-Jenny is referred to as a self-factor.

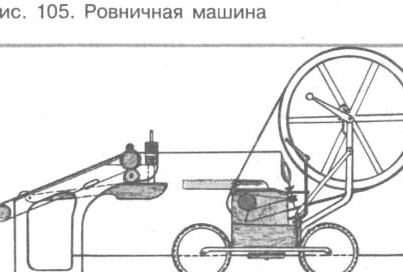

As a child measles, the inventors were ill with the idea that the spinning machine is necessarily a roving machine (Fig. 105). The wool that was previously combed and rolled up into thin tubes was stacked on a movable table. From here, the raw materials moved to a pair of clamping rollers. A gear rack attached to the movable carriage produced a roving, since the clutch with the gear transmission to the rollers worked. When the roving production stopped, the carriage could still move away, pulling the thread, which significantly improved the quality of the yarn.

At the beginning of the 19th century, a steam engine was used to help the spinner. One person from now on exerted as much as 320 had done 40 years before. In comparison with this Hercules, his work in captivity might seem like a resort. It is no coincidence that with such fierceness, Luddites broke machines, gaining followers throughout England.

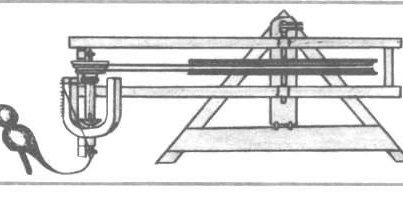

With a known skill, a modern woman will spin the required amount of wool by turning on the electric spinning wheel. When this device is not in the house, you can do with other devices. About eight-ten years ago, including because of the price, prefixes for the sewing machine, which were produced in our country by several factories, were very popular. I must say that the consoles do the same thing as electric spinning wheels - they spin the thread of both the left and right twists, the required thickness, twist the yarn, increase or decrease the twist of the thread, as necessary. The prefix, which will be discussed, was designed at the Teplopribor Ryazan plant and is focused on a household sewing machine with foot and electric drives. This includes machines: class 2M — 22 “Podolsk” (classes 132–22 and 142–22), “Seagull 132 M” (class 132M – 22) and “Seagull 142M” (class 142M-22).

First of all, the sewing machine is switched to idle. If it is with a foot drive (Fig. 106), from the side of the flywheel 1 you need to release the friction screw 2 and turn it towards you. In the sleeve 4 from the side of the flywheel 1 there is a hole for the thread. A fixing bolt 5 with a washer 6 is mounted on it with a screwdriver or wrench.

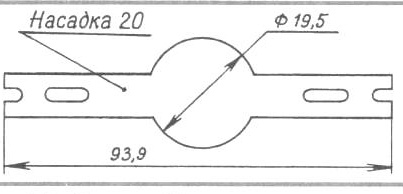

The spinning wheel itself (Fig. 107) is a fixed axis 14, which is fixed with a screw 10 on the bracket 3. A flyer is freely mounted on the axis, this is a pulley 12 and two hexagonal rods 15. On each rod there is a slider 16 with holes 17 for yarn passage. The coil 13 on the axis is held by a brake ring 18 having a latch 19. A nozzle 20 with holes 21 and 22 and a groove 23 for passing yarn is placed on the free ends of the rods and axis. The nozzle has two more holes 24, with which it is mounted on the rods 15.

To a machine with a foot drive, the spinning wheel is installed using the insert 11, it is placed between the bracket 8 and the machine. The bracket should stand so that the rubber ring 9, mounted on the pulley 8, touches the flywheel 1 of the sewing machine to the right of the groove under the foot drive belt, and when the flywheel 1 rotates, the spinning pulley 8 does not slip. Too tightly pressed pulley will complicate the work of the spinning wheel, it will have to be slightly removed from the flywheel without breaking the touch. After adjusting the position of the spinning wheel, tighten the fixing bolt 5.

On a machine with an electric drive for left-handed twisting, the small rubber ring 9 is removed from the flywheel 8, a large rubber ring is pulled onto the flywheels 8 and 12. An insert is not needed in this case. The clutch of the pulley 8 with the pulley 12 of the flyer is produced by moving the hinge screw into the groove of the bracket 3 while loosening the wing nut 7.

If the spinning wheel went hard, the adjusting screws adjust the position of the hexagonal rods 15 on the pulley 12.

The wool holder is placed in a convenient place on the left, on the table of the sewing machine (Fig. 108). The clamp is fixed to the edge of the table with a screw, and a plastic sleeve and plug are successively put on it. The wool is tied to a fork. A meter piece of the waste thread is hooked at one end to the spool, the other is tucked into the holes of the spinning wheel (Fig. 109) and connected to the tow fibers.

The flyer begins to rotate from the intermediate pulley 8. He, as already mentioned, pulls out a rubber ring 9 worn on it and the rim of the flywheel 1 of the machine, and the flyer pulley. The flyer will move to the right or left, determines the rotation of the flywheel of the foot drive.The yarn is curled while the flyer is in action. The free end of the yarn, which has not gone all the way, is controlled by the hand near the raw material holder, watching for a smooth fiber feed. Since the thread is held by hand, there is some tension, which causes the spool to rotate. If the spool and the flyer spin at the same speed, then the yarn is not wound, gaining navivas. Slightly letting go of the thread, we reduce the speed of the reel, due to friction on the brake ring, it will go even slower, yielding to the speed of the flyer. Therefore, the finished yarn will begin to be wound on a spool. The tension of the yarn is regulated by screw 10. When a thick thread is spun or when long fibers are used, the tension needs to be stronger so that the spool accepts the finished yarn better.

The sliders (Fig. 107) are moved along the rods of the flyer. So gradually the thread will fill the spool along the entire length. To do this, the slider with the yarn tucked into it is rearranged with the spinning wheel idle. One flyer rod and one slider sitting on it are involved in the spinning. The one whose opening is opposite to the spinning direction of the spinning wheel is selected for refueling. The full coil is removed by squeezing the flyer rods 15 with your right hand (see arrows in Fig. 107), and with the left hand removing the nozzle 20. After that, press the latch 19 and remove the brake ring 18. Replacing the coil, return everything in the reverse order - first put the brake ring 17 so that its latch 19 fits into the groove on the axis 14, then, pressing the rods 15 of the flyer, attach the nozzle 20.

The designers themselves recognize the vulnerability in the console as the springs in the sliders 16 and the axis 14 from the side of the adjusting screw 10, which are inadvertently easy to disable when adjusting and disassembling.

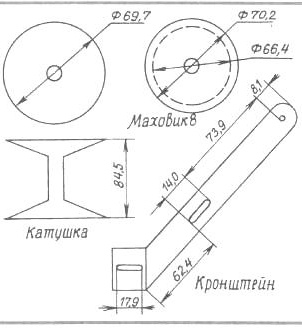

We will name the main dimensions of the spinning-wheel attachments. The diameter of the plastic reel is 69.7 mm, the height is 84.5 mm. Flywheel 8 has an inner diameter of 66.4 mm and an outer diameter of 70.2 mm. The remaining information is in the drawings: bracket 3 (Fig. 110), flywheel 12 (Fig. 111l), brake ring l7 (Fig. 111), nozzle 20 (Fig. 112).

Yarn succeeded - there is hope to make a beautiful thing that would warm the soul. No matter what fashion imposes, no matter how zealously it pushes foreigners into eternal learners, we still have special sympathies and unfading interest in knitted scarves, stoles, scarves, and shawls. They are knitted from a thin woolen thread with a continuous fabric and openwork pattern, often with downy additives.

In the South Urals, women craftsmen, perhaps in the twentieth generation, are engaged in knitting from purely goat Orenburg fluff. Once, goat fluff was used only in work clothes. Cossacks discovered its splendor to the whole world, knitting shawls with lace borders or fully lace from fluffy threads. There were craftswomen, whose scarf fit in the shell of a goose egg. There are no such awards, no matter what the Orenburg buttons are marked. Their products at world and international exhibitions were sold at prices higher than gold.

For centuries, the scarf remained the best decoration of a woman. He was celebrated like a fur coat, once in a lifetime and for a lifetime. Worn over clothes - from snow dust, air penetrates into the fluffs, keeping warm between them. And if a cotton scarf is pulled up under the downy boards, let winter storms, as she pleases, you won’t chill, you won’t get cold, you can endure any winds. Pooh does not like it when it is worn under clothes, grows old, fibers (long ones - first of all) are compressed, erased, dumped, rolled up in lumps. The same thing, by the way, is observed with mohair if things from him are put on under a jacket, cloak, jacket.

Prior to spinning, in combed-down comb, fluffy hair was selected for clearance by hands. It took winters all day. All homeworkers were occupied - from small to large. On the manor houses worked girls, not yet able to spin. In A Childhood of Bagrov the Grandson, S. Aksakov describes how the old lady, the hero’s grandmother, spun down herself while the yard girls sat around looking for coarse hair in downy fibers. And it was worse that the negligent who misses at least one Austin. The lady kept a whip at hand ready.

A warm shawl was knitted in large - 600-1000 stitches - from two threads (down and so-called shlenka, plain paper), thin silk was woven in the openwork shawl of the second thread. Spinning thread was not used.The scarf turned out to be a square with a side under two meters. Openwork was made even larger, it was enough to cover my head, folded eight times.

The downy thread is hidden abruptly - up to 180-200 turns per meter. Therefore, the Orenburg shawl new for the first time does not look very fluffy, but rather even resembles a pair of hair tied in half. But everything is easily verified. Firstly, semi-downy is heavy. Secondly, a shawl of good down rests on weight if you lift it by a feather. Only after falling into snowfall three times, the hostess notices that the update is gradually starting to push.

From year to year, the scarf is more magnificent. Five years later, it is washed in a very mild soap, like a baby’s, or in children's shampoo. Along the entire perimeter prior to washing, the teeth are evenly and fairly firmly pressed onto strips of cloth or gauze 10-15 cm wide. In advance, usually a wooden frame should be prepared where the straightened square of the scarf with a mark will fit. On all sides of the frame, nails are stuffed about 1 cm high at a distance slightly larger than the tooth from the tooth. It is also necessary to leave a stock of 2–4 cm between the side of the scarf and the frame.

After washing and without rinsing, a wet handkerchief is pulled onto pieces of wood, piercing nails through the edge of a fabric or gauze strip. Dried without sunlight, away from heaters, stoves, radiators. The handkerchief removed from these was even more tender and affectionate. With a solid viscous wash every once in ten years, white, delicate cobwebs - annually. I know that some people prefer to put things in order with less troubles, stitching a spider line on a sheet before washing or putting a handkerchief directly on the frame with their teeth. The sheet does not retain its shape, the knitting is compressed, and the teeth both rust and tear. With traditional care, my handkerchief serves the fourth decade, even though I exploit the thing mercilessly. Moreover, this is not an exhibition copy and is not associated with a celebrity.

Choosing a real downy shawl has always been great luck. It is gratifying that the craftswomen on the bottom, its entire part, adapted to knit on a machine, only the border was manually knitted. From this, the scarf did not become worse, on the contrary - the middle, which is abraded before the ends, is stronger and smoother in machine binding. However, in the markets you often find a miserable parody of the Orenburg shawl. You are lying in the eye, offering a fake from a string yarn, with a synthetic base, God knows what is mixed in the yarn, and the unfortunate fluffs keep their word of honor, utterly shaken with a comb. From a fine pure-wool yarn, a scarf will be incomparably better next to this, if I may say so, downy.

They say that living by the sea rarely swim: where, they say, it will disappear tomorrow! So with regard to crafts. A. Benoit predicted at the beginning of our century that, having received his sight, we will regret the original folk products, but they will become a rarity and antiquity. Orenburg shawls and cobwebs are very rare, maybe you can’t name it. Excellent shawls are produced by the local factory. In her solid warm shawls, up to 70% of down, a little less - in openwork ones. And the one who acquired such a thing is no doubt satisfied. But these are other products that differ from those bound by hands.

From time to time, attempts are made in the Orenburg region to revive a unique craft and raise a new generation of knitters. True, for some reason they are trying to raise the ball by the string. Once again, they sit down at the spinning wheel in whole classes. At the end of the 50s, I remember that a pink-cheeked girl Lucy Rul with a string bag of green onions appeared at the All-Union construction site of the Gaisky mining and processing plant. I ran away from home, from the famous down-knitting village, after the first failures in training. Cried: "What, me myself in these loops, or what?"

Serious knitters are in most cases those who undergo training at home, with mothers and relatives. They will show their cherished tricks, and support in a simple everyday sense, because we spend time on anyone, but they don’t find money on creators.The needles have not yet been released from the hands of the elderly - all the undergone elder.