Tool:

Bulgarian

caliper

scriber

square

drill

punch

6mm drill

grinder brush

cutting wheel 2mm

Material: 10mm square

To begin with, we clamp the blank of the square into a vice

mark the middle of the square with a bar along 5 mm

measure the lengths of 1 cm across the square with a bar

then use the square

We mark the line with the square and scriber through the marks in the center, at an angle of 45 degrees, on all four sides. After that, core on the marks

Kernim also on 4 sides

We drill holes with a depth of 3-5mm, a drill with a diameter of 6mm.

Repeat drilling on each side

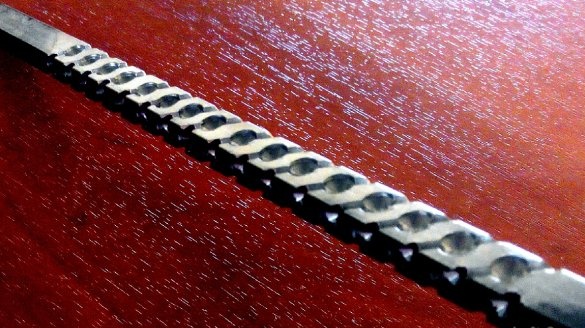

We make cuts at around 45 degrees with a grinder, with a cutting wheel thickness of 2 mm

Then we turn the workpiece in a vice and cut the grooves on the other sides

We remove burrs from the workpiece with a brush on the grinder

Interesting torsion is ready

The manufacturing process on video

Bulgarian

caliper

scriber

square

drill

punch

6mm drill

grinder brush

cutting wheel 2mm

Material: 10mm square

To begin with, we clamp the blank of the square into a vice

mark the middle of the square with a bar along 5 mm

measure the lengths of 1 cm across the square with a bar

then use the square

We mark the line with the square and scriber through the marks in the center, at an angle of 45 degrees, on all four sides. After that, core on the marks

Kernim also on 4 sides

We drill holes with a depth of 3-5mm, a drill with a diameter of 6mm.

Repeat drilling on each side

We make cuts at around 45 degrees with a grinder, with a cutting wheel thickness of 2 mm

Then we turn the workpiece in a vice and cut the grooves on the other sides

We remove burrs from the workpiece with a brush on the grinder

Interesting torsion is ready

The manufacturing process on video