I thought about buying a tripod. Having looked at prices in stores and on the Internet, it turned out to be a rather expensive toy. And those that were cheaper did not inspire confidence and small ones. Then the idea came up to do it myself. Polypropylene (PP) pipes fell into my eyes, and I will do them.

What is needed:

Materials:

- PP pipes for 20 and 32 mm.

- PP plugs at 20 mm.

- PP coupling 32 mm.

- articulated extension for the brush (it was written on the price tag)

- cold welding

- 8 mm bolts.

- bolt (stud), 6 mm nut.

- 8 mm washer.

Instruments:

- Soldering iron for PP pipes

- hacksaw

- file

- drill (screwdriver)

- drill

All you need to make a tripod is. You can get to work.

I cut from 20 mm. pipes 3 pieces of 450 mm. I solder the plug from one end of the pipe.

I melt the other edge on a soldering iron to make a small side. Next, I will explain why this side.

It should be something like this.

Now you need to shorten the 3 hinges by about 10 - 15 mm. (I sawed off only 8 mm. It turned out to be small. Sticking out into the pipe.)

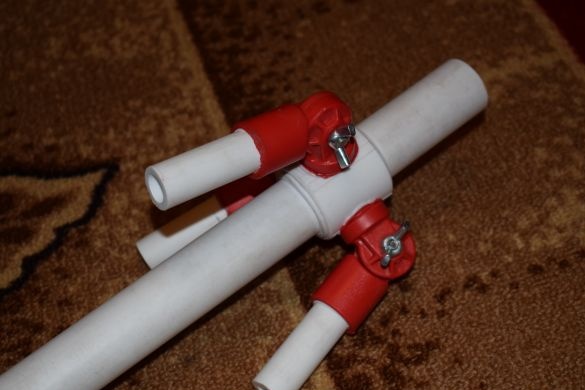

I cut three 20 mm. 100 mm pipes. I put 20 mm collets on the soldering iron. I solder these pipes with hinges. I don’t know what plastic the joints are made of, but they are tightly soldered.

I cut 32 mm. 400 and 100 mm pipe. I install 32 mm on the soldering iron. collets. I solder pipes to each other through a sleeve.

I mark and drill three 19 mm holes on the coupling. at the same distance from each other.

I solder the hinges into the holes in the coupling.

I cut three 32 mm. 450 mm pipes.

Since 20 mm. the pipe does not fit snugly into 32 mm. I didn’t invent the pipe much. Wound electrical tape 20 mm. pipe and inserted it into 32 mm. the pipe. She dressed very tightly, I thought I would break it, but no, everything turned out to be very durable.

Now I take 20 mm. pipes to which the plugs were soldered. Due to the fact that 20 mm. the pipe comes in 32 mm. I didn’t melt the pipe tightly. The resulting side must be finalized with a file to freely enter 32 mm. pipe, but at the same time did not dangle in it. I collect. On the other hand, I am sealed with cold welding. Pre-wound 20 mm paper in one layer. pipe so that cold welding does not stick. As cold welding hardens, I remove excess paper.So I do on all the legs of the tripod.

The cut is approximately 600 mm. from 20 mm. pipes. On the one hand I’m melting the pipe to get a side (as I did before). I insert it into the central 32 mm. a pipe (with a sleeve which). Only after that I solder the hinge to it. It does not need to be shortened.

I also fix it by cold welding. In my case, additional fixation is not required, the central pipe moves tight, does not fall down.

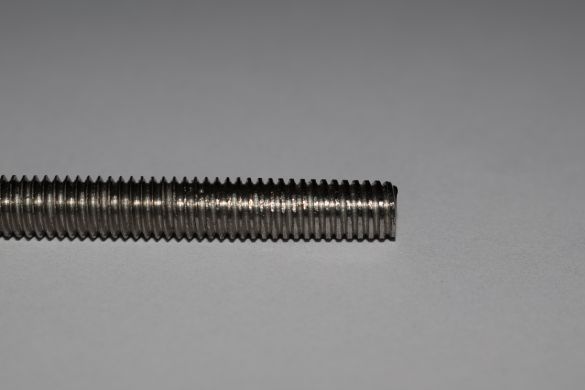

Now you need to make a mount for the camera. There are several ways. One is to buy a ready-made mount, for example in China, then you do not need to solder the hinge, there the whole structure is assembled, or do it yourself. I decided to do it myself (wait a long time until it arrives from China). The thread of the camera turned out to be 1/4 inch (6.35 mm.), I did not find such a bolt. With a little refinement, a 6 mm bolt is suitable. I take the pin 6 mm. I grind the thread a little with a file (I used a hairpin because I have a lot of them).

I cut the hairpin about 40 mm. I drill a 5 mm hole in the hinge. I heat the hairpin, solder it into the hinge. I installed a washer in the hinge so that the teeth do not catch.

I tighten the nut. It is needed to adjust and fix the camera. Better to pick a nut more comfortable, put what happened.

To fix the telescopic legs, I used an 8 mm bolt. It is better to use with a wing handle, it is not convenient to carry the key in your pocket all the time.

On the bottom of the central pipe, either solder the plug or melt a little from the inside so that the pipe does not fall out.

Here's what happened.

Conclusion

This tripod is more for home use than for professional use. The minimum height to the bottom of the camera is 670 mm. maximum 1430 mm. In the most unfolded state, it is very stable. Folded takes up little space. I hope you enjoyed this article, but homemade will be helpful.