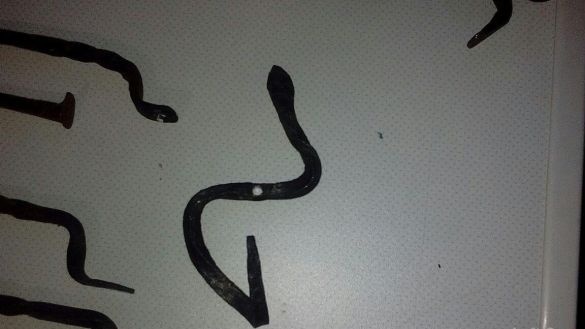

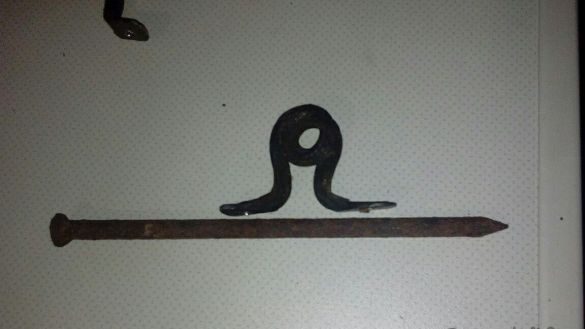

This is what I am doing from old nails. Antique pens for of furniturehangers and so on. All this business is heated on coals. But is it possible to heat a steel nail 3-4 mm thick with red-hot current? I tried welding, but it apparently goes into defense, 250A is not enough. I probably need some kind of resistor.

Or can make what type of transformer for "quick soldering iron"?