Often we need to bend something thick. In the absence of appropriate tools, such as a pneumatic press, we have to do this manually, which is not always easy. Especially for such cases, you can make a miniature pneumatic press, which will greatly facilitate the work.

Before we begin the process of manufacturing a pneumatic press, let's see the author’s video, which shows and describes the whole process. And after that we will repeat everything on our own.

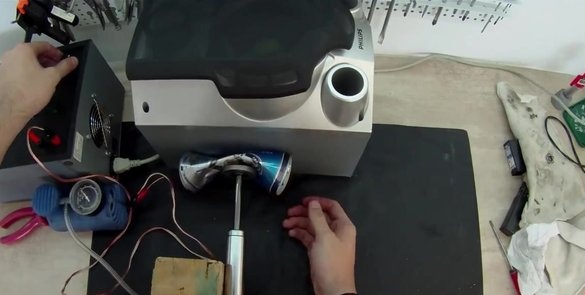

We will need:

- shock absorber from a pneumatic chair;

- fitting for 3 mm;

- air pump;

- hose

It should be noted that making an air press from an old office chair is extremely easy. First, we need to mark the location of the fitting with a marker.

The next step is to make a hole in the marked place and fasten the fitting. Care must be taken to ensure that the fitting fits perfectly and firmly. Also, do not forget about sealing, otherwise our pneumatic press will not have sufficient power, which is understandable.

Next, take a hose. We connect one end of the hose to the fitting of our pneumatic press, and the other to the air pump. The press is actually ready.

It works according to the following principle: air from the pump enters the press. The fitting does not allow air to evaporate. When enough air accumulates in the shock absorber, it becomes necessary for him to get out of somewhere, which he does by pushing the rod out of the shock absorber to the outside.

For greater efficiency, a round metal piece can be attached to the end of the rod, which will press on objects, spreading the force of pressure over a large area.

Our pneumatic press is ready. It copes with relatively easy tasks. It can be used to bend metal frames, metal and aluminum cans. Such a press will be useful for those involved needlework and often come across thick sheets of paper that are very difficult to push through with your hands.

Again, we note that this is still a crude version of the pneumatic press, which can be improved if desired, increasing its capabilities. You can also use the system of the chair itself, which has four holes for the bolts and makes it possible to attach the press in the workplace.