Lovers electronic homemade have long known that printed circuit boards can be manufactured in home conditions. We suggest that you familiarize yourself with the material in which we will consider a method of manufacturing printed circuit boards using the LUT method or laser-iron technology. The essence of this technology is in the thermal transfer of toner, followed by etching.

The author of the video, which we suggest watching right now, shows the method using the example of the Marx Generator

What we need:

- laser printer;

- a computer;

- textolite;

- scissors for metal;

- solvent;

- Nitric acid.

Not all laser printers are suitable for LUT PCB manufacturing. The printer that the author uses has gone out of official production, however, you can find information on suitable printers on the network.

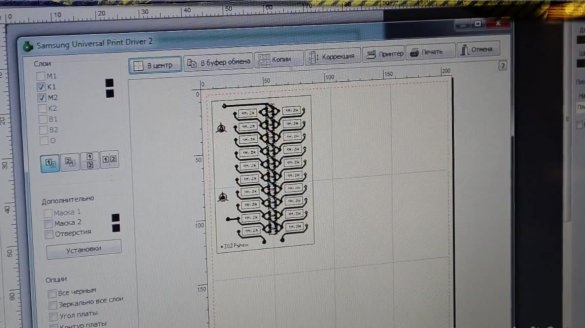

So, first of all, we need to draw a circuit diagram in a graphics editor on a computer. To draw a diagram, the author uses the program "Sprint Layout". After that, you need to print the resulting image in a mirror image.

For printing, it is recommended to use glossy photo paper for inkjet printing measuring 10 by 15 cm. You need to print on the glossy side.

Next, we take the textolite and cut the piece to the size of the board with scissors for metal. Degrease textolite with solvent.

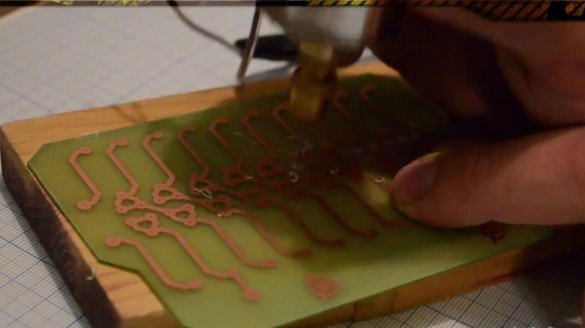

We apply the printed pattern to the PCB and iron it with a heating close to maximum. The resulting image is then mirrored in relation to the printed image.

Now for cooling we hold the paper under a stream of water. Tear off the paper from the PCB.

Pieces of paper will definitely remain on the future board. They can be removed with an unnecessary toothbrush.

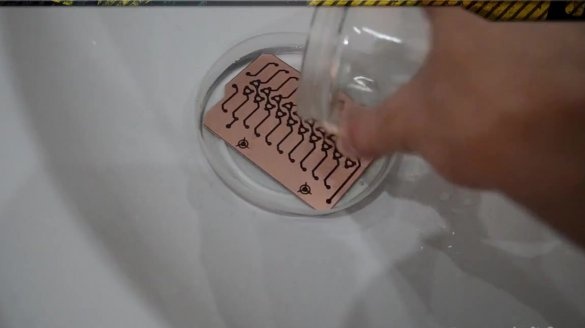

After that, you can start etching. You can use any available tool for this. The author uses nitric acid, which can be replaced with ferric chloride, ammonium perchlorate, a mixture of hydrogen peroxide, citric acid and salt, as well as a mixture of copper sulfate and salt. For complete etching, you need 2-3 minutes.

We actively wash the circuit board with water and wash the toner with solvent

We drill a board with a drill whose diameter is approximately equal to the diameter of the terminals.

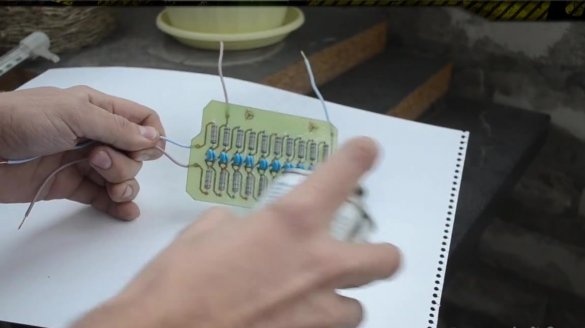

Next, tin our board and solder the parts.

Cut the sticking out leads with wire cutters.

We remove rosin or active fluxes with alcohol.

To better protect the board from moisture from electrical breakdown, the author recommends covering it with a special polyurethane varnish.