Fishermen use a large number of various devices during fishing. Especially with winter fishing. In order to facilitate your movement on the ice course, you should unconventionally approach this issue - for this you need to create a sled for winter fishing.

Making your own sleigh for winter fishing is not so difficult as it might initially seem. With all this, for this you need an aluminum sheet, as well as a profile. It should immediately be noted here that the sizes of such sleds should be chosen based primarily on their own preferences. These sleds will consist of only the main three parts - more precisely, of the standard side walls, bottom and runners.

Step 1. First you need to draw a drawing of your future sleigh or print the diagram itself, having previously found the Internet. Well, after that you need to start carefully marking the material. First of all, you need to do the cutting of all the aluminum areas of the sled itself.

Step 2 It will be very good when you also have at your disposal a standard bending machine, but if it is not there, then in principle it is possible to get by with an ordinary steel corner or a mallet. But both sidewalls should be solid, then there is an option - you should cut a solid metal part, and then bend it so that you get two equally sized sidewalls, as well as the back wall. Then you need to make the bottom using the same technique. It is also important to remember that the edges of the sled must be safe, so it’s best to bend them right away.

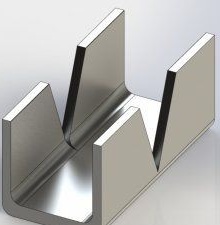

Step 3 At the next stage, you just need to make the skids themselves, they only need to be cut from a pre-prepared aluminum profile. The most important thing at this stage is to correctly calculate and mark everything, and then carefully make simple cutouts in places where the runners will bend.

Step 4 At the last final stage, it is necessary to begin the full assembly of the winter sleigh and only any fasteners, including self-tapping screws intended for metal, will be needed here.

It is possible to make the connection by using nuts and bolts.In general, there are a whole bunch of options, so you don’t need to cook anything with a welding machine.