- A pretty handy thing when hunting, fishing, or even on defense. The force of compressed air cannot be underestimated; on the basis of such energy, it is possible to produce quite powerful weapons. The most promising weapon can be considered pump action. It has a special chamber, as well as sediment, which pumps the desired pressure into the chamber. The most interesting thing is that the power of the shot depends on the volume of the chamber and the amount of compressed air in it, which means that you can make a gun of such power as you need.

Specifically in this article we will look at how to make a simple pump-action based on cycling pump. The manufacturing technology is quite primitive, which makes it very simple and cheap, hello to you from the masters from Cambodia!

Usually the most difficult part in making such a weapon is the valve, which should open instantly when you pull the trigger. But there is no problem with this, the trigger device is made very simple and works great. How? Read on!

Materials and tools that the author used for homemade:

Material List:

- a piece of PVC pipe and two plugs (for the camera);

- a piece of soft hose;

- wooden beam (for the base);

- steel wire;

- self-tapping screws;

- sheet steel (for brackets);

- steel pipe for making a muzzle;

- two steel clamps;

- a piece of gum from the camera;

- Bicycle Pump;

- two copper tubes (for connecting hoses to the container).

Tool List:

- epoxy glue (or cold welding);

- screwdriver;

- pliers;

- welding or soldering iron;

- a small hammer.

Gun manufacturing process:

Step one. A few words about the compression chamber

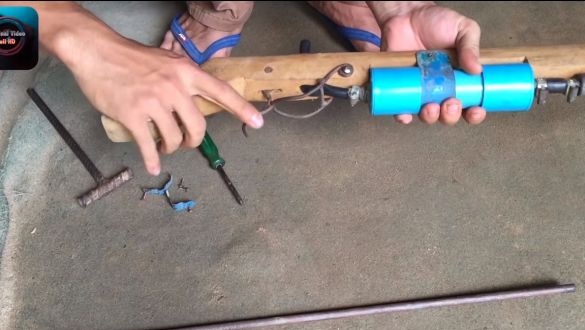

All details in this homemade product were already made in advance, the author only shows us how the gun is assembled. The camera is a piece of PVC pipe on which plugs are installed. The plugs need to be fixed well and glue may not be enough, it is advisable to screw them in additional. The main thing here is that the chamber be airtight and withstand high pressure.

On each end of the camera there is one fitting. Pipe pieces are suitable as fittings, do not forget that they must have a sufficiently large inner diameter to quickly release air. We drill holes under the tubes and install them using epoxy glue, cold welding or something similar. It would be nice if the fittings were on the thread.

Further. A piece of soft rubber tube is installed on one fitting, it is black in the photo. We wind the insulation onto another fitting, a pump is connected here. If the pump does not have a check valve, then it must be present in the system. Fum tape is suitable as insulation.

As for the size of the camera, it’s all individually here. In principle, only one shot is fired here, so making it too big makes no sense. In pump action shotguns, the camera is very small, however they are quite powerful. it is not volume that matters to us, but the air pressure in the chamber.

Step Two Set on the basis of

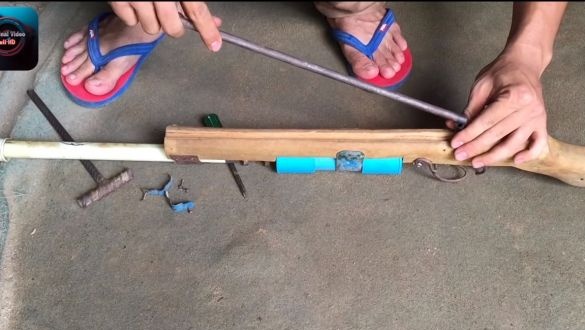

As the basis for the gun, the author used a wooden block, which was given the desired profile. Here you need to work with a knife, drill several holes and so on, in general, there is nothing complicated.

We conduct a black hose, and we fix the compression chamber using mild steel sheet. Make mounting brackets from it in the shape of a camera, and then screw it to the base using self-tapping screws. It is advisable to put rubber under the clamps, a bicycle camera is suitable as it.

Step Three Install the pump

The system is fed through a small bicycle pump. First of all, we connect the pump to the chamber. To do this, use a small piece of rubber hose, as well as two steel clamps. Tighten the clamps well so that no air is poisoned anywhere.

That's it, now you can fix the pump itself on the gun. It needs to be fixed securely, since when pumping air it can easily be torn off. The author fastens it with just one clamp, but this is not a very reliable solution. Place an elastic band between the clamp and the pump so that the pump does not slip.

You can check the system for leaks. Pinch or close the black hose with your finger and try pumping air into the chamber. If it doesn’t poison anywhere, everything is fine. It is also important for you to make sure that the check valve is working in the pump. If it is working, the pump piston will not spontaneously extend under air pressure. The valve is usually located at the beginning of the hose, it consists of a small ball. The author etches the valve a bit, so the piston spontaneously extends.

Step Four We fix the trigger device

And now about the most interesting! How to make a trigger device for instant air supply to the barrel? Very simple, here we will need that black soft rubber hose that goes to the barrel from the camera. To shut off the air supply, simply transfer the hose.

To clamp the hose, a special design is used, which is made of steel wire. It can be welded or welded. This design is fixed with the trigger. When you pull the trigger, the instant hose is unclenched and air from the chamber enters the barrel. This whole thing is fastened with the help of two screws and one metal pin, which is hammered into a tree and holds the trigger. Moving parts must not wedge.

Step Five Install the barrel

The author uses a steel tube as a muzzle. We connect to it a black hose that comes from the camera. We fix this whole thing with a metal clamp so that the hose does not disrupt with high pressure. The barrel itself also needs to be firmly fixed. This will help you homemade steel clamps and rubber bands from the cameras. For reliability, it is desirable to mount the barrel in at least two places.

The gun is ready! Do not forget to make sure that the tree does not absorb water. Moreover, it can change in size, crack, get dirty, rot and so on. It is advisable to soak it with linseed oil, or you can simply paint or varnish.

Step Six Gun testing

The gun is ready, you can begin testing. First of all, you must block the black hose with the trigger. Then you can begin to pump air into the chamber.How much to pump it, everything is already determined experimentally. The most important thing is not to pump air, since too high pressure can break the compression chamber. Air pressure should be such that the bullet has time to develop its maximum speed, which is determined by the throughput of the barrel and other nodes.

Try to shoot from a gun and remember how many times you need to pump air to fire.

Now a few words about shells. The author did not mention how he shoots the gun, most likely steel balls from bearings are used as bullets. But how to load them in a gun? Very simple, we throw the ball through the barrel so that it falls to the very beginning. To fix the ball in this position, you can install a small magnet here. Now the shell will never drop out of the barrel when searching for prey.

But balls are not the only thing that can be fired from air guns. Here it is quite possible to use arrows. The advantage of using arrows is that the barrel does not have to be perfectly smooth and rifled so that the gun has a high accuracy. It is also convenient to hunt fish with the help of arrows, since with an arrow the fish will not swim away far.

In principle, that’s all! Good luck