Hello,

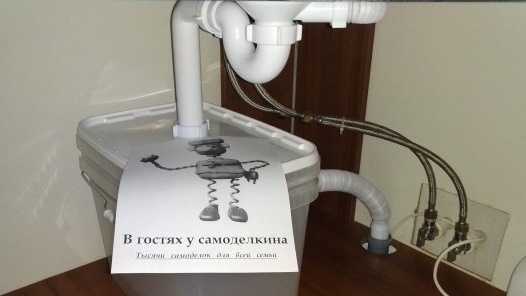

Today, do it yourself - household bucket grease trap with integrated cartridge.

I bring to your attention a description of the product, completely ready for manufacture and operation in the form presented.

Having tested different designs, I was convinced that convenient cleaning is very important, so I decided to make an option with an integrated cartridge, and by making a second cartridge, you can collect and remove grease by simply changing the cartridge without servicing the container itself.

After some time, of course, the tank itself will have to be serviced, but it will not be necessary so soon.

The grease trap consists of three main parts:

Capacities

Covers

Cartridge

The cartridge, in turn, is a specific design for separating fat, and consists of two main parts:

Cartridge capacities

And no complicated overflow system

Capacity

Material for capacity:

According to the principle described below, a grease trap can be made from almost any container, the main condition is their identity and a hermetically sealed lid, and the efficiency of separating fat will depend on their volume.

Since the plastic food container fully meets all the basic requirements, and I chose it, it should be noted that the dimensions, as well as adapted By me, the materials presented in the publication are valid only for this capacity.

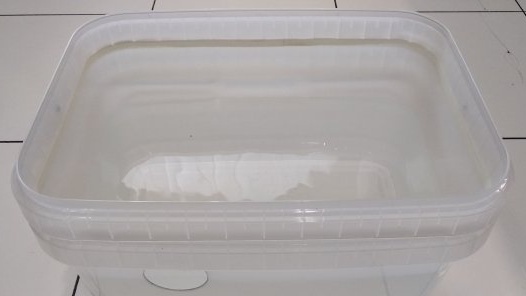

Bucket - a food container of 20 liters. (remove the handle) - 1 pc.

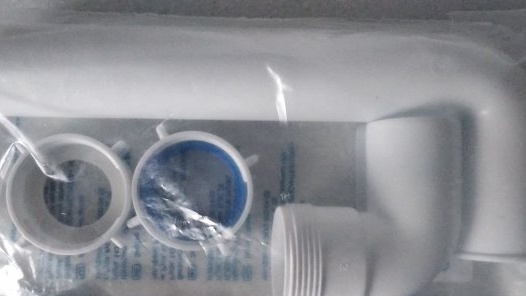

Old siphon - 1 pc.

Outlet elbow 1½ ”× 40 without outlet - 1 pc.

Transitional cuff 50/40 - 2 pcs.

Rubber ring 53 × 45 × 4 mm. (or something suitable, for example, a whole or cut along the sealing ring from the sewer pipe PP 50) - 2 pcs.

Capacity manufacturing:

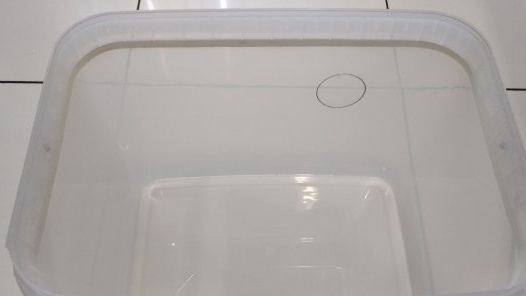

Both in the lid and in the container itself, it is necessary to make holes for the inlet and outlet pipes.

The diameters of the holes depend on the purchased rubber cuffs.

Prepare trimming transition cuffs.

Prepare pipe cuts with 1 ½ "threaded portion.

From the old siphon.

From the branch knee.

To mark the holes for the inlet pipe - you need to insert a piece of pipe with a threaded part into the cuff, and measure the outer diameter between the cuff collars.

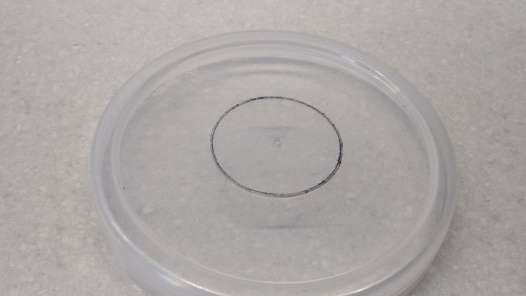

Having reduced the measured diameter size, and taking into account the density of the cuff material, cut a hole in the center of the lid of the food container.

Install all elements in the prepared hole.

A rubber ring is needed to press the outer collar of the cuff against the thin lid of the food container.

In the same way, you need to mark and cut a hole in the container for the outlet pipe.

Install all elements in the prepared hole.

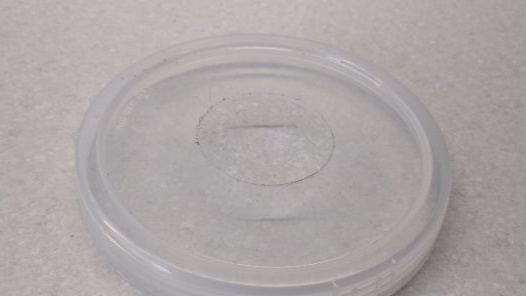

The capacity and lid of the household grease trap are ready.

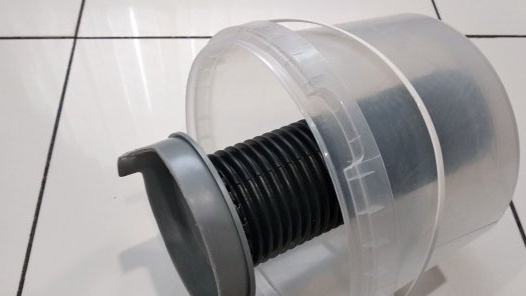

Cartridge

Material for cartridge:

Bucket - food container 20 l (leave the handle) - 1 pc.

Food container 3 l - 1 pc.

A small food container (with a threaded lid with a diameter of about 100 mm.) - 1 pc.

Outlet elbow - 1 pc.

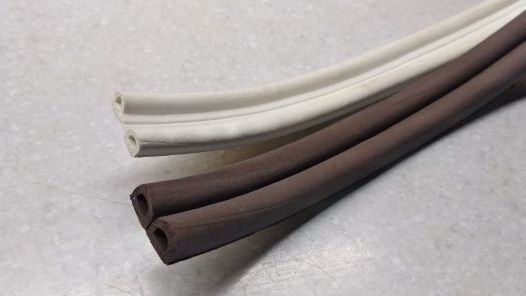

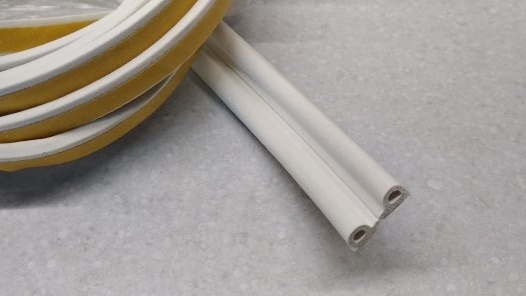

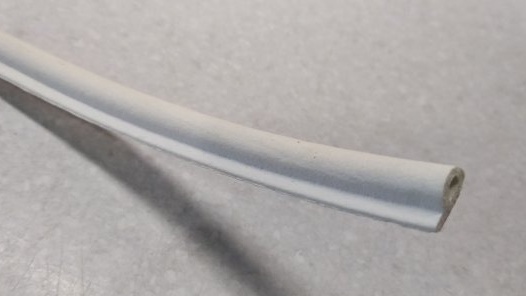

Self-adhesive sealant - 1.5 m.

Air filter pipe (UAZ-3163 Patriot art. 3163 -1109192) - 1 pc.

PP 110 plug - 1 pc.

PP 50 cap - 1 pc.

Pipe PP 50 L - 250 mm. (without o-ring) - 1 pc.

Issue 1 ½ "with stainless steel mesh (without gaskets) - 1 pc.

Cartridge manufacture:

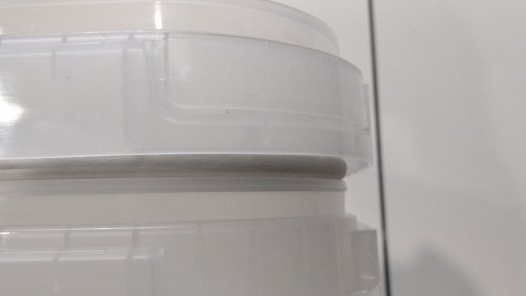

On the outside of the cartridge, under the stiffeners, having previously degreased the surface, fix the seal.

It is better to use a sealant type (P).

When separating the seal in two, a small plane is obtained, which is then inserted into the container during assembly, centering the cartridge, thereby ensuring a more reliable tightness.

Insert, prepared for the manufacture of the cartridge, a food container in an already manufactured container.

Fill 3/4 of the total volume with water (this is to take into account the shrinkage of the sealant, under the weight of the poured water), and note the location of the hole cut out in the tank for the outlet pipe.

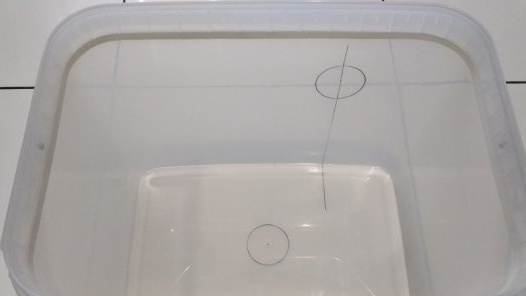

In the center of the bottom of the food container, mark a hole Ø 50 mm., Under the outlet 1 ½ "with a stainless mesh.

Concerning the center of the previously applied mark of the location of the hole cut out in the container for the outlet pipe, draw an axial line along the wall with the transition to the bottom of the container.

In the center of the bottom of the food container, cut a previously marked 1 ½ "outlet with a stainless mesh.

In the bottom of the food container, at the edge, mark and cut a hole Ø 40 mm., Whose center should be on the marked center line.

In the center of the marked mark of the location of the hole cut out in the container for the outlet pipe, mark and cut a hole Ø 100 mm.

The diameter of the hole depends on the selected food container, in its threaded part.

Cut the threaded part (the bead retains when cut!).

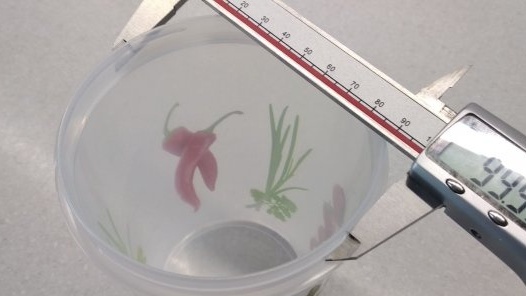

Next, make a hole with a diameter of 38 mm in the center of the threaded cover. (after manufacturing the bypass pipe, the diameter of the hole is adjusted to the diameter of the groove made on it).

Drill three Ø 6 mm holes at the edge of the threaded cover.

Next, make a bypass pipe.

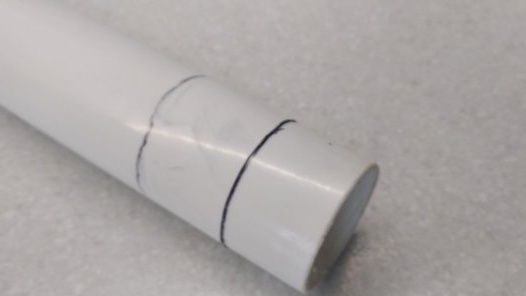

Shorten the elbow from the small shoulder to 10 mm. from the corner.

From the resulting edge at a distance of 3 ÷ 4 mm Using a marking caliper and a fragment of a hacksaw blade, make a groove about 1 mm deep.

Having adjusted the diameter of the cut-out hole to the diameter of the groove, fix the prepared threaded cover (without play, rotate freely).

Insert the long shoulder of the elbow elbow into the hole in the bottom of the container, align the screw cap with the wide hole in the side and secure.

Make a mark at the bottom for the release of the shoulder of the branch knee.

Trim, putting 30 ÷ 35 mm away from the intended mark (depends on the selected distance of the nozzle edge to the bottom of the main tank (5 ÷ 10 mm)).

Install the bypass pipe to the specified location, with the holes drilled, at the edge of the cover, up.

Fasten 1 ½ "outlet with stainless steel mesh to the bottom.

Cartridge capacity is ready.

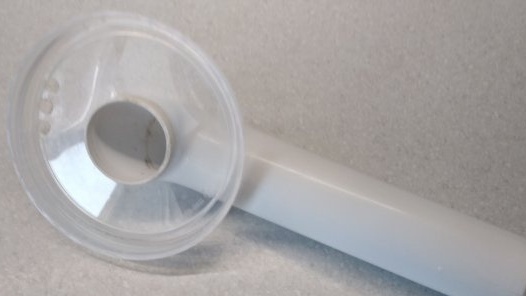

Next, you can begin to manufacture the release of the cartridge.

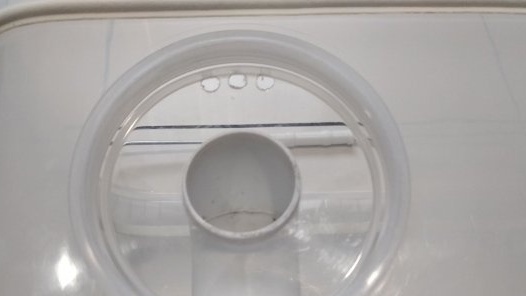

Cut a hole Ø 50 mm in the center of the PP 110 plug.

Mark the edges of the stub from opposite sides and make 2 cuts to a depth of 10 ÷ 15 mm from the edge.

In the middle of the bell of the PP 50 pipe, from opposite sides, mark and cut 2 grooves with a width of 10 mm or simply drill 6 holes of Ø10 mm each.

In the assembled grease trap, the water level in the cartridge will be determined by these grooves, and ultimately should be higher than the water level in the container, which means that the cartridge will not pop up and will be firmly pressed through the seal to the container, eliminating the penetration of unpleasant odor into the room.

Cut the pipe along the length determined by the total height of the release in the assembled state, which, in turn, is equal to the height from the bottom to the latched cover of the cartridge (for this food container the height is 240 mm).

The length of the cut pipe in this case will be 188 mm.

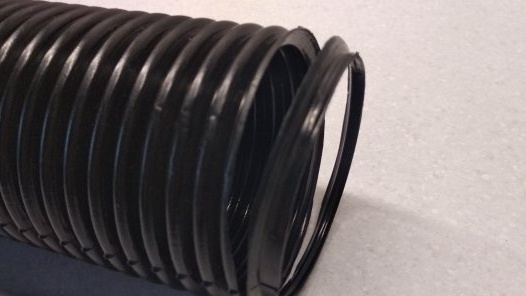

From the air filter pipe, make a casing for the cartridge outlet pipe (in principle, you can use a pipe of any configuration (round or square) with an internal size of 65 ÷ 80 mm).

The casing does not allow floating fat to penetrate the PP 50 exhaust pipe.

The length of the casing pipe is determined by the height from the bottom to the cartridge cover by zaminusovaya height of the plug 110.

The length of the casing in this case is 205 mm.

The final length of the casing, due to the mismatch of the desired size with a cut along the edge of the corrugation, may be slightly larger, which is well compensated by the pressure of the lid when assembling it with a corrugated structure (one of the advantages of the selected material).

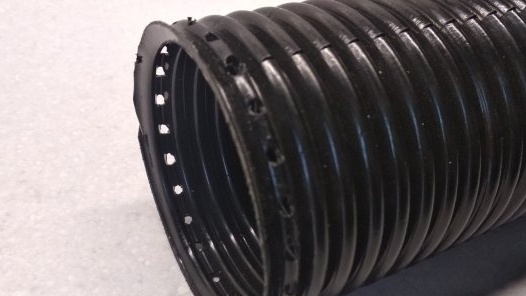

Along the edges of the casing pipe, after pricking (marking) with a “gypsy” needle at a distance of 10 mm from each other, make holes 4–5 mm with a drill or just a soldering iron tip.

In one row for air circulation on one side.

And in two rows for water intake from the other.

If the purchased pipe turns out to be smaller (for example, 200 mm), then holes, those in the same row for air circulation, do not need to be made.

Next, make an overflow receiver from a three-liter bucket of food container.

In the center of the bottom, cut a hole Ø 67 mm corresponding to the outer diameter of the inner crest of the corrugation.

This hole needs to be made more precisely so that the future overflow receiver fits snugly between the crests of the corrugation (another advantage of the selected material).

In the hole, install the prepared casing so that the edge of the overflow tank is between the water level in the cartridge and the air holes of the casing.

In this embodiment, inside the 7th inner ridge.

Assemble the cartridge release.

Release cartridge assembly.

Install the release into the cartridge.

Grease Cartridge Ready.

If necessary, make a replaceable cartridge in the same way.

Assemble the grease trap from the prepared components.

A grease trap with an integrated cartridge - ready.

Recommendations:

If a replacement cartridge is to be manufactured, then a removable exhaust receiver consisting of a PP110 plug, a three-liter bucket, a casing and a PP 50 plug can be used for both cartridges.

Before starting operation, as well as after changing the cartridge, the grease trap should only be filled with cold water.

Due to the smell, the replaceable cartridge will have to be stored in a suitable garbage bag.

Conveniently, if it is possible to visually control the accumulation of fat, for this purpose, a cutout can be made in the grease trap cover and a “eye” made of transparent plastic can be installed.

That's all.

Good luck

Good luck

More information on the assembly and some of the nuances during operation, in the video on my channel on YouTube.