The all-terrain vehicle is ready for the next test.

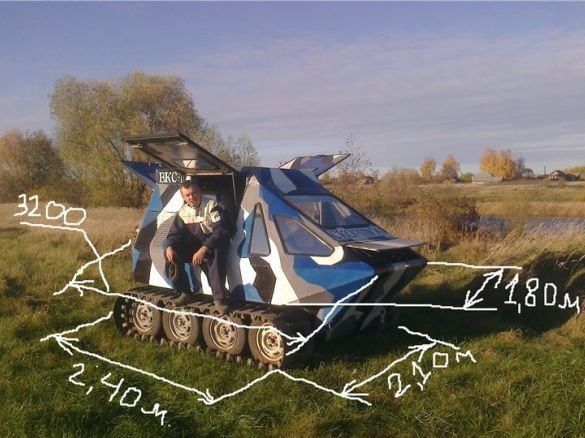

Builder all-terrain vehicle "VKS-1" Sergey.

All-terrain ride to the river. video.

The initial performance characteristics, during the construction and running-in, much changed and was rebuilt many times, indicators improved.

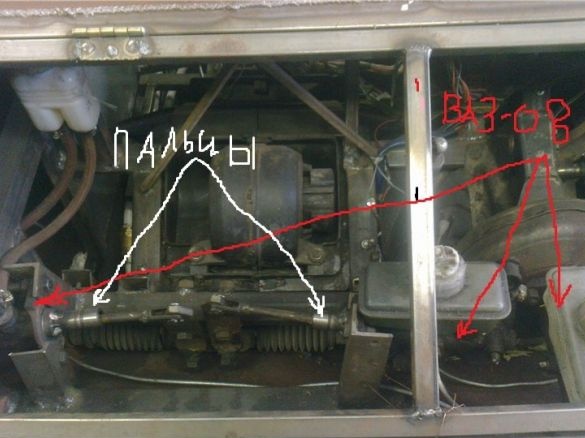

The engine from the VAZ-2108.

Bridges from the VAZ-2101.

Reducing gear-transfer case from the car "Niva".

The rotation of the all-terrain vehicle occurs due to the braking of the drive wheels and the operation of the differential.

Track drive without drive sprocket, but with drive wheel.

Road wheels firmly sit on the axes welded to the hull of the boat.

For swimming, the propeller from the Whirlwind is used, mounted on an axis from the hub of the VAZ-2108 with rotation.

All mechanisms are located in a sealed hull-boat.

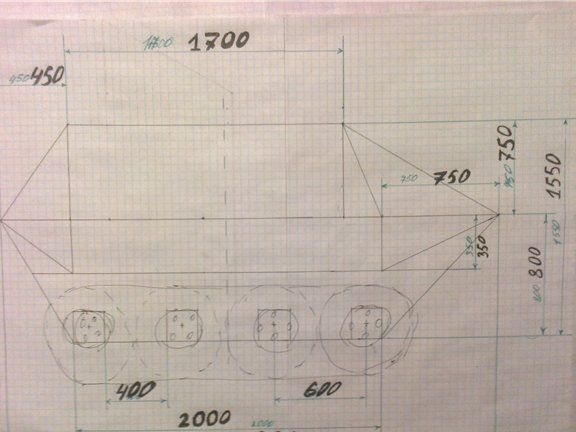

Dimensions:

The height of the boat is 800 mm.

The width of the boat between the wheels is 1050 mm.

The width of the boat above the wheels is 1850 mm.

The length of the bottom of the boat is 2000 mm.

The total length is 3200 mm.

The boat frame is brewing.

The rear axles are welded into the boat frame.

The front of.

The boat is scalded.

An axis of fastening of basic wheels.

Wheel hub

The main tool for building is electric welding.

All axles are welded to the boat.

The bottom of the boat is primed.

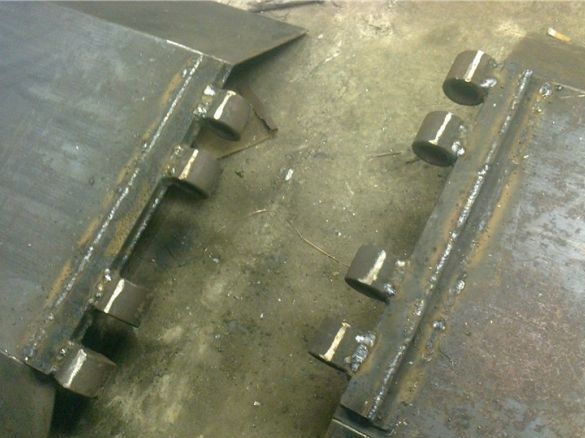

Guide fangs made.

The tracks are screwed to the tape.

Tape 8 mm thick, 6 layers of cord. The tape was used on a sawmill.

The caterpillar is ready.

The propeller from the Whirlwind is mounted at the stern of the boat.

The screw can turn, thereby steering.

The screw is seated on the front hub of the VAZ-2108.

The screw receives rotation from the gearbox, the differential is welded and the screw rotates constantly.

The engine from the VAZ-2108 is installed in the middle of the boat.

The front grenade transmits momentum to the drive axle.

Turnovers are transmitted through the clutch, gearbox, RK "Niva".

The shaft is shortened and welded.

The side is scalded.

The side is primed.

Rear end.

Front view.

Work with electrical wiring.

Mounted on the engine is going.

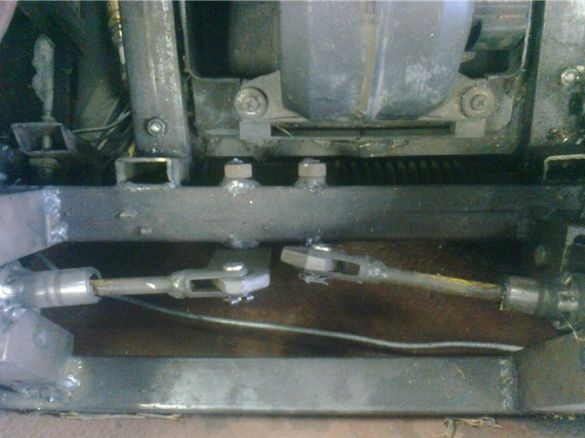

Homemade track tensioner.

Caterpillars are dressed.

The first test drive. video

Work has begun on a second pair of tracks.

Self-made dressed in new tracks.

Alteration of the top of the cabin to increase space for passengers.

Break-in continues. video.

Calipers fell off, reinforced with 10 mm metal.

They drove a screw without water. video.

Bathing. video

How is the management of an all-terrain vehicle implemented? After all, there is a steering wheel, and not levers like everyone else.

The steering rack, levers are welded to it, which, through the axis, press on the brake cylinders taken from the VAZ car. The levers are made of metal 9 mm thick.

Brake cylinder mount.

Hydraulic tanks are located on the right.

Fingers from the VAZ-2108 are welded on tacks.

A sheet of aluminum with rivets is riveted to the roof; it is coated with sealant between the sheets.

Glazed in a circle.

Painting from all sides.

The roof is completed.

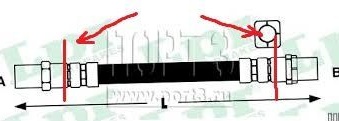

Method for passing brake hoses through a boat.

The brake hose from the VAZ-2108 is cut according to the marks, you can even use a torn hose.

The result is a fitting.

The ends are welded together.

The fittings are welded into the boat and brake pipes are screwed from the inside.

Outside, the brake hoses from VAZ-2101-07 are screwed.

A full-time vacuum box from the VAZ-2110 is installed for the brake. Four calipers are installed on the front axle, two of them are used for turns and two only for braking during descent from steep slopes. On the rear axle, brakes are only for cornering.

Now it’s worth it.

Calipers are not visible behind the wheel.

Brake pedals in the cab.

Running-in showed flaws in the cooling system. He installed the box, replaced the thermostat, set the broken one. Two fans work almost without stopping, the temperature does not rise above 90 degrees. The radiator installation diagram.

Finished box for cooling.

All cracks are sealed.

Expanded slots for air intake.

Video on the fans.

The engine compartment is glued with foil insulation, and on top of it with kavrolin for sound insulation. The generator is installed more powerful at 80 Amps. Hatch for air intake made with control from the cab. A winch for a knife is installed. The knife will be made in the form of a folding butterfly.

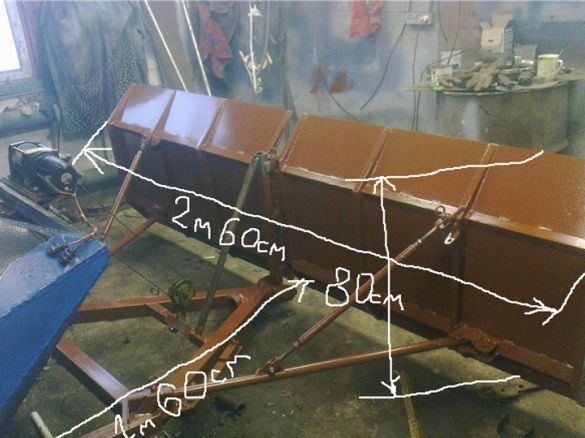

Cutting metal for a knife.

Bending sheets.

The second side is bent.

It turned out two halves of one knife.

Two halves are connected by a shaft.

Welded eyes.

Reinforced knives.

Central rack between two dumps.

Drove a knife.

Reinforced knife mount.

The fastener drove the knife to the all-terrain vehicle.

Middle rack knife.

Two halves of a knife are collected in one dump.

Reinforcement of heaps using profiles.

The bending points are reinforced with a corner.

The lower edge of the knife is also reinforced with a corner.

Snow cleaning with a new knife. video

Additional supports are attached.

The whole structure is painted with red lead.

The knife is drying.

The knife now has eight positions.

It remains to install the central screw.

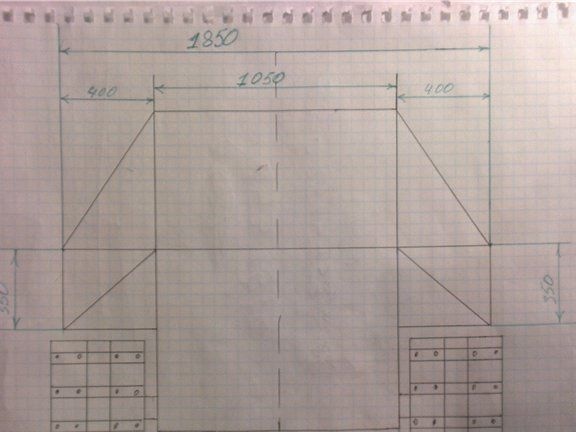

Dimensions auto-make.

Dimensions of the knife.

Stripes were cut out of truck tires to fit knives from the bottom.

The knife turned out to be full and ready for operation.