The eternally interesting topic for the manufacture of various knives sometimes does not imply the creation of knives.

In this article, Sergey, the author of YouTube channel "SteelWood" will tell you how he made a "decorative" machete, in which part of the butt can play the role of a torch.

This model will not have much sharpening, everything is purely decorative.

Materials

- Sheet steel 3 mm thick

- Old tire and chain from a chainsaw

- Steel pipe

- Metal dishwashing sponge

- Connecting rod from the engine

- wire

- M6 nuts and bolts

- Elastic bandage

- Glue, gasoline.

Instruments, used by the author.

-

-

- Cutting and flap scraping discs

- Brush wiper disc

- Magnetic plate

- Hammer, anvil

- .

Manufacturing process.

So, the first thing the master marked the future contour of the workpiece on a steel plate, and cut it with a grinder.

By the way, for the convenience of processing parts, the author uses such a magnetic plate. With its help, you can quickly fix metal workpieces.

A couple of the main details are ready, now the author wants to weld a piece of chain to the butt. To do this, he cuts off the main working teeth of the chain, leaving only the guiding shanks.

Then he grabs the chain to the butt in several places.

To connect the blanks, he will use sections from a regular motorcycle chain.

Welding the chain links to the workpieces, it turns out like this.

Next, he will need to make a handle. For this, a steel pipe is suitable. Cutting off the workpiece of the required length, flatten the pipe with a hammer on the anvil.

The pipe sat on the liner very tightly, and was welded to it.

As a guard, the master decided to use a paired chain.

Wrapped around the handle, and welded a chain to it.

Now it remains to make a shank, for this the author picked up an old connecting rod.

Trim the excess material, and grind it down to the size of the pipe.

Welded the workpiece from the connecting rod to the handle.

Now Sergey will manufacture fuel tanks. For this, a chrome tube is suitable.He cut it into two parts along.

He cleaned part of the butt, and tried on blanks. They will be on both sides of the canvas.

It is important to make a sufficiently tight bottom seam so that the fuel does not spill out. The upper seam is made with small holes.

Next, the author took a metal sponge for washing dishes, and densely filled the voids in the containers.

Now you need to brew the end of the tank.

In addition, the author welded M6 nuts, and drilled a hole in the tank. This will be a kind of filling hole, which will be closed with a trimmed M6 bolt.

Using a metal brush strips all surfaces of the machete.

As a winding handle, he uses a regular elastic bandage. Coats the handle with glue, and wraps it with a bandage.

The edge of the bandage also lubricates with glue, and tucks it into the previous turn.

Now it forms multi-colored metal stains to give it a more interesting look. It simply overheats the metal in several places with a gas burner.

Finishing the master made decorative descents.

Refills the gas in the tank and closes the plugs.

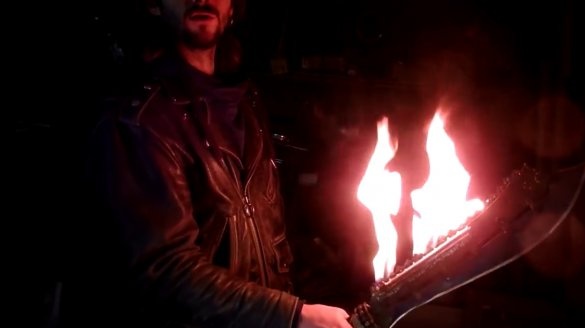

Well, the work is finished, now you can set it on fire. Gasoline filling is enough for only a few minutes, but the flame turned out to be very impressive in size. To increase the burning time, you need to reduce the size of the upper holes, or increase the capacity.

Thanks to the author for a very original idea of the design of a fire machete!

All good mood, good luck, and interesting ideas!

Author video can be found here.