Hello lovers to work with metal, today we will consider the original knife, which is entirely made of metal. The knife handle covers are made of brass, after polishing the whole thing looks quite interesting. The author cut the blade out of already hardened steel. Looks homemade quite interestingly, the author sharpened the blade to a razor state, the homemade product easily shaves the hair on the author’s legs. In manufacturing, the knife is not complicated, but you will need a grinding machine, since hardened steel cannot be processed in any other way. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- brass plates;

- carbon steel for the blade;

- brass rods (for pins);

- epoxy adhesive.

Tool List:

- tape cutting machine;

- belt sander;

- drilling machine;

- oven, oil, oven (for heat treatment);

- clamps;

-;

- drill with carbide cutters;

- polishing machine;

- oil (for coating metal).

The process of making a knife:

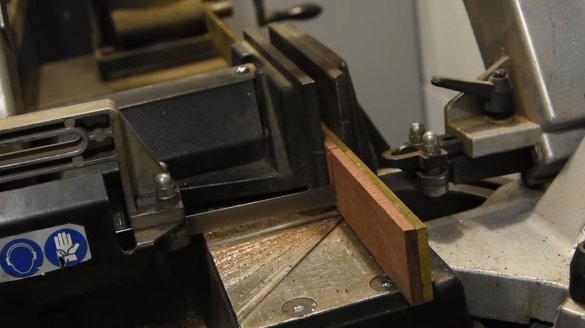

Step one. We prepare materials for the handle

To begin, prepare the materials for the plates, we need sheet brass of suitable thickness, as well as not thick boards, which will be needed only for processing the handle. We cut the blanks, glue the boards to the brass blanks, you can use superglue as glue. We also need to drill holes for the pins. The author used brass rods as pins.

Step Two Steel heat treatment

The author decided to harden steel in advance, so as not to jeopardize the finished blade. We heat the steel to a red glow and dip in oil. In order not to cause an unpleasant surprise in the form of cracking and deformation of steel, the oil can be heated with a hot piece of iron. The author tempered only the tip of the workpiece, where the potential body of the blade will be located.

We check the hardening with a file, an experienced master can determine whether the steel is hardened or not, by sound, if you knock on it. Usually hardened steel rings.We grind the steel plane so that the oxide film is visible during the tempering process, and we send the blade into the oven. The temperature is usually set in the region of 200 degrees Celsius and takes about an hour. As a result, the steel should be covered with a straw-colored oxide film, darker colors may indicate a deeper tempering, but it all depends on the steel grade.

Step Three We assemble and form the handle

On the hardened steel plate you can install the handle, for this you need to drill holes in the area of the handle for the pins. This must be done before hardening, if you harden the entire body of the knife. We glue the pads to the workpiece using epoxy glue, tighten everything securely with clamps. Leave the glue to dry in accordance with the instructions.

Next, we need a drill, using it we will form the desired profile of the handle. You need a powerful drill with a good carbide milling cutter that can handle steel. As a result, the author quite easily forms the handle profile. After that, it will be possible to remove the wooden parts and grind the handle on a belt grinder.

Step Four Blade

We proceed to the formation of the blade, draw the desired profile and cut it with a grinder. In this matter, it is important to understand that our steel is already hardened, so that its overheating will lead to tempering and it will be necessary to temper the blade again. Constantly cool the blade with water.

As for the descents, their author formed by eye with the help of a grinder, a thick grinding disk or a petal nozzle is suitable for such purposes.

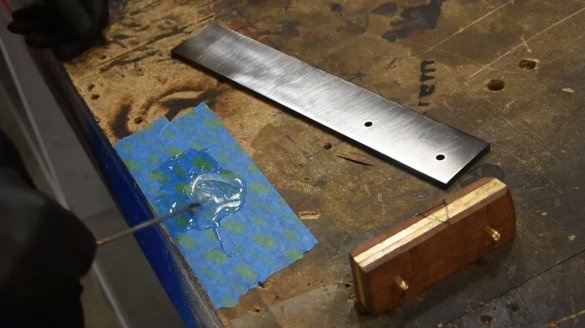

Step Five Handle refinement

We need to bring the handle to a mirror state, seal the blade with masking tape and proceed to grinding and polishing the brass. The grinder again came to the aid of the master. For rough processing, you can use Velcro and fine sandpaper. At the end, we carefully polish everything with the same grinder or on a polishing machine. As a result, the handle looks amazing.

Step Six The final

In the end, you need to sharpen the blade to a razor state, for such purposes the author used a polishing wheel and abrasive paste. You can also use special grinding stones, which also help sharpen the knife to the state of the blade.

That's all, now the knife is ready, cover it with suitable oil so that the steel does not rust and the brass does not darken. The knife is so sharp that the author shaves his hair on his leg. On this this project is completed, good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!