Each time, watching all new videos, sometimes I am convinced that their number and degree of danger are growing exponentially. Maybe some DiVaiVai geniuses are born in a sapper costume, but there is no certainty about this. I am not Dr. Dew, however, I join his indignation.

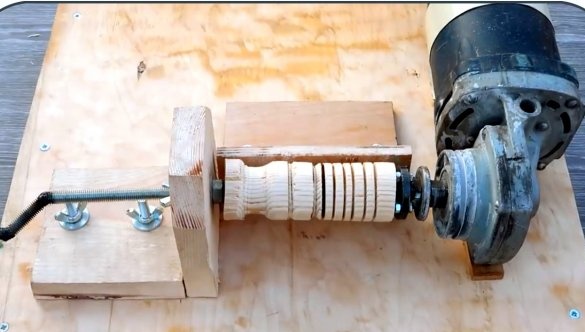

In this article, the author of the YouTube channel “INVENTOR” will show you his bullshit. This time, another inventor will try to create a lathe based on a grinder.

By the way, a small survey is posted below the text of this article.

PySy. Repetition of this homemade product is harmful to your health!

Materials

- Boards, sheet plywood

- Nut M14, bolts M10, M4

- Steel stud, wing nuts, washers

- Wood screws.

Instruments, used by the author.

— Bulgarian

- Cutting and flap scraping discs

— Screwdriver

— Welding machine

— Electric jigsaw

- Pliers, vise

- Wrench and gas wrenches

- Ruler, pencil.

Recommended remedies:

- Helmet, body armor, dry ice, sterile bandage, bags, formalin, diapers.

Manufacturing process.

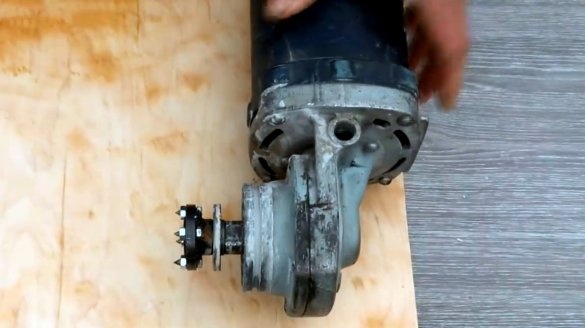

So, let's begin. Of course, the "maestro" removes the protective cover, removes the clamping nut and washer.

He picked up four bolts, but they were too long, and they had to be slightly shortened.

In short, fixing the bolts in the cartridge, he grinds them to the condition of the spikes.

Now, from these bolts and the clamping nut, he makes such a studded flange.

Yeah, the author has a desire to strengthen the design with another M14 nut. However, it does not fit between the bolt heads.

Yes, and the dog with it, the nut can be turned on a flap flap disc to such a degree of curvature. Now she intermeddle.

So, what's next for us ... Ah, the author has a welding machine. In short, he welded the nut to the washer.

What, author, is scary? It is necessary to tighten the self-tightening nut with a gas wrench. Better immediately weld to the spindle, yeah.

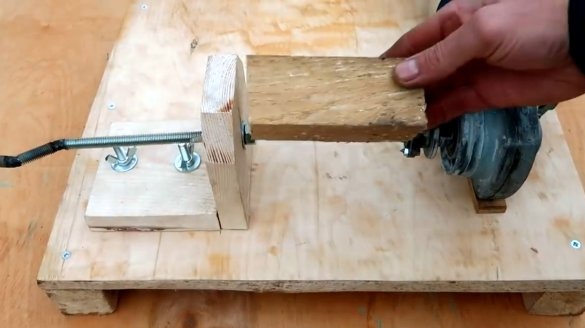

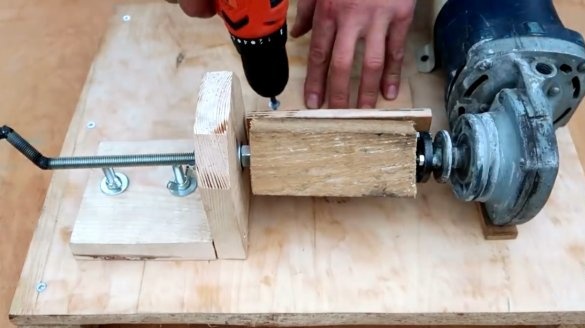

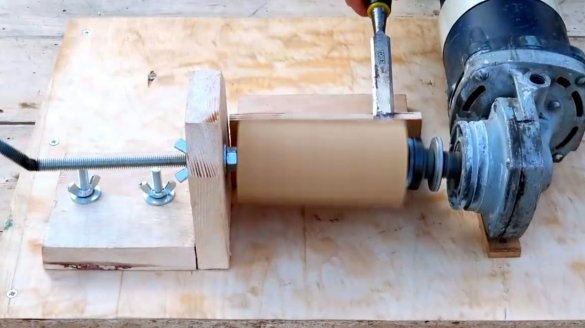

Are you bored? There used to be flowers.Now the berries begin. A grinder is attached to a plywood sheet with one M10 bolt and a flimsy clamp for a pair of self-tapping screws.

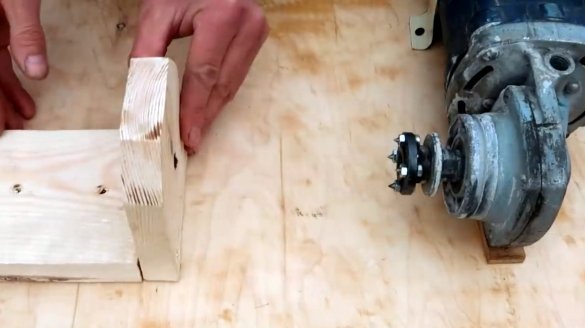

More fun! It is necessary to make the tailstock of two bits of boards, screwing them with a pair of screws even without pilot holes.

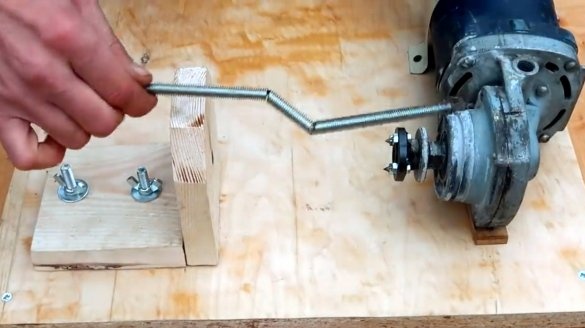

So, the tailstock must be movable!

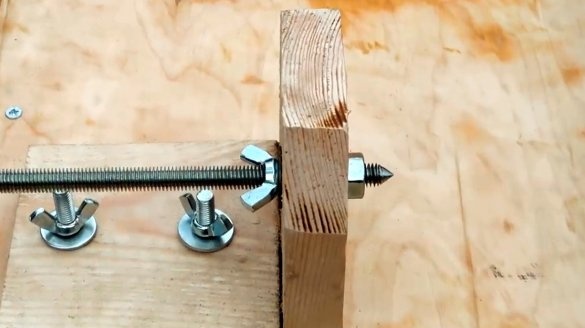

To do this, a pair of holes for the clamping screws are made in its sole, and a hole for the clamping screw in the rack.

I said grandma should be mobile. This will run like that, yes.

Two holes are drilled at the base, and a slot is made between them. It seems to me alone that even the author’s jigsaw is sawing sideways?

Next, the headstock is screwed to the base with a pair of bolts with wing nuts.

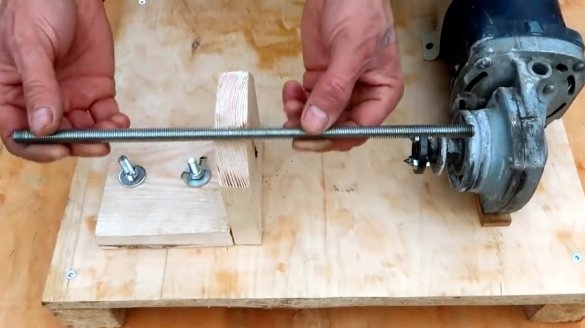

A sharpened hairpin will be used as centering.

Bullying is not finished yet, and a L-shaped handle is made on the hairpin.

And now attention to the tailstock stand! It is already warped almost 20 degrees from the vertical only when trying to install a workpiece! And what would you like if it is fixed on two metal screws?

Of the two pieces of plywood, the author made a support for the incisors. Yes, the same quality as before.

But why did he screw it tightly to the base? After all, it is the emphasis that should be adjusted not only by the distance from the workpiece, but also be able to be installed at different angles to it.

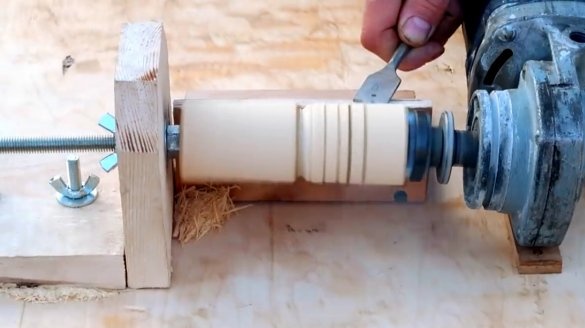

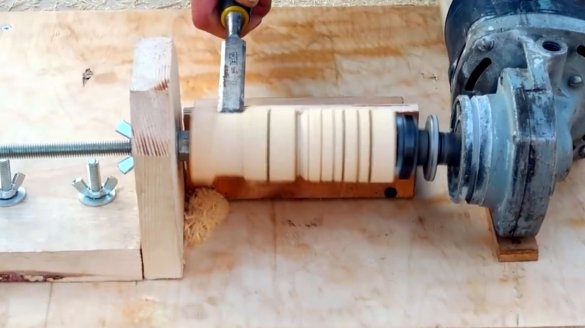

So, the rotation of the upper part of the workpiece is "to the author." Turning the chisel upside down, he tries to grind the square billet to the state of the cylinder.

Well, then - sheer insanity. The smoke goes by.

Further actions of the author with a pen drill on a tree in his hands. I already can’t describe it without the Russian mat.

So, this “inventor” is awarded the Matveev Prize in absentia! And if he continues to do so, he will also receive the Darwin Prize. Also in absentia.

To the author - more whole fingers, head, and brains.

All good mood, good luck, and interesting ideas!

And if you have good ideas or homemade projects, then you can share them on this site for a real fee, rather than a green note at various entertainment forums.

Author video can be found here.