In this article, the Master will share his experience in manufacturing a rocket furnace. Such an oven can be used quite widely, from home to going to barbecue or fishing.

Tools and materials:

Profile pipe 120X120X3;

Profile pipe 25X25;

Profile pipe 20X20;

-Sheet metal;

-Fittings;

-USHM;

-Welding machine;

-Drill;

-Roulette;

-Marker;

-Gon;

-Magnetic corners;

-Clamp;

- Fireproof paint;

-Wooden handles;

- Wing nuts + bolts;

Step One: Firebox and Fuel Hopper

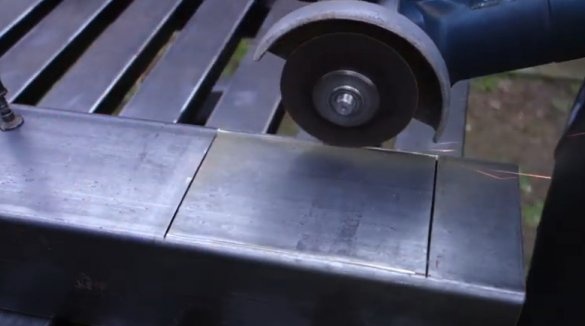

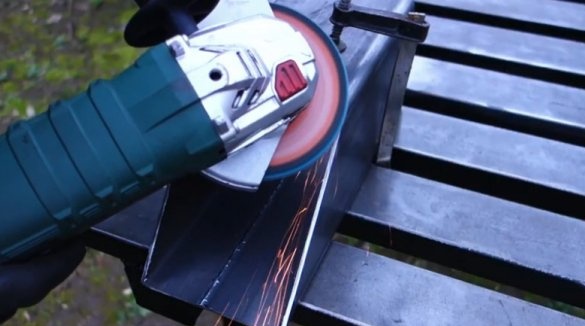

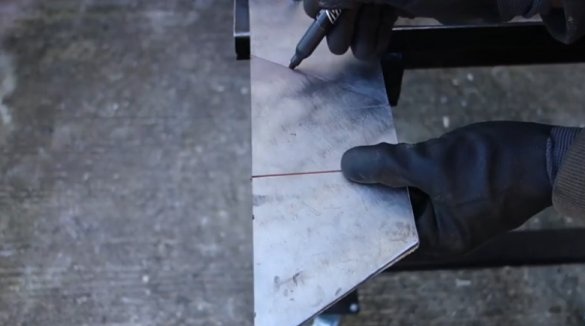

First of all, the master prepares the material. The furnace itself and the fuel hopper will be made of 120 profile pipes. Slices the blank for the furnace.

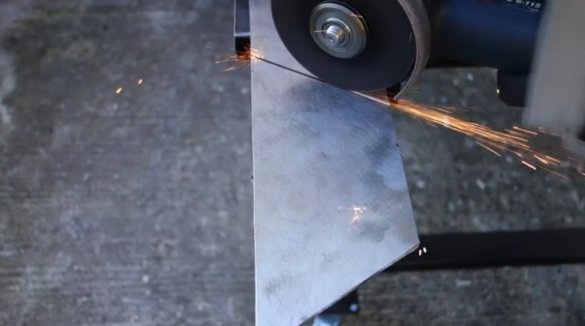

Cuts the workpiece for the fuel hopper. One end of the workpiece cuts at an angle.

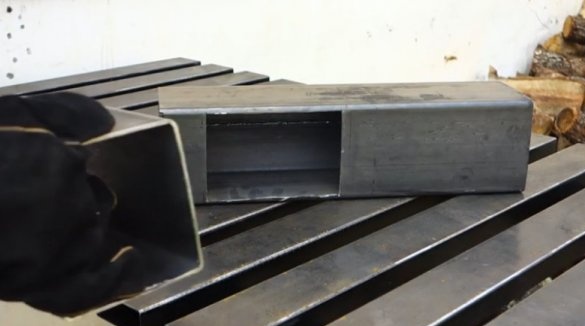

In the blank, which will be a furnace, cuts a hole. In the future, the fuel hopper will be welded here and the master will adjust two mating surfaces.

Step Two:

Cuts workpieces for legs, also at an angle. The legs are made up of several parts. One part will be welded to the furnace. The second will be inserted into the welded tubes.

At the ends of the movable legs, mobile platforms will be fixed. For their manufacture, the master cuts semi-circular blanks. They need 9 pieces.

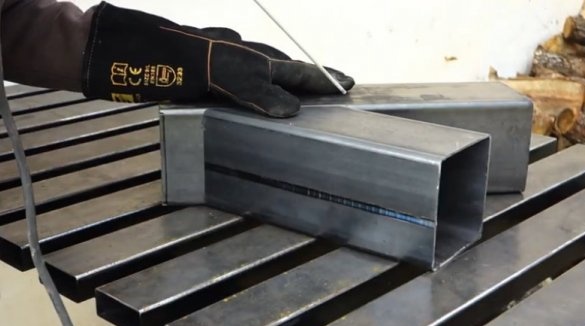

Step Three: Firebox, Fuel Hopper

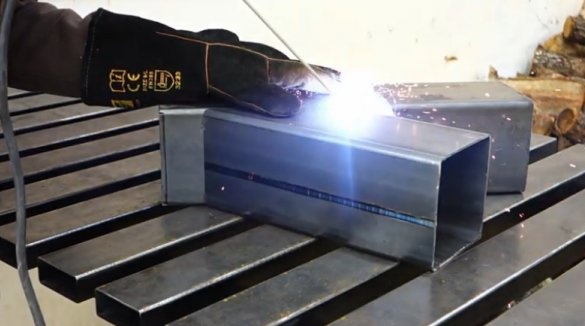

A fuel hopper is welded to the firebox.

Three strips of metal are welded to the bottom of the furnace.

Step Four: Feet

Welds the legs.

Now you need to make the movable part. First, the master cuts three segments of the 20th profile pipe.

Edges the edges of the blanks in a semicircle. Drill holes.

Slices three pieces of a metal rod.

Welds a movable platform.

Step Five: Top

Cleans a sheet of metal.

Cut four trapezoidal blanks.

Welds them at the top of the firebox.

Step Six: Partition

Divides the fuel hopper into two parts with a metal sheet.

Seventh step: door

Makes the door to the fuel hopper.

Step Eight: Miscellaneous Trivia

Drills holes in welded legs and welds nuts. Screws bolts with a lamb into nuts.

Makes and welds a handle.

Welds the grate to the top and the ash pan.

Stains the oven with high temperature paint.

Sets the legs.

The oven is ready.

Now you need to check it in work. The master loads fuel and ignites it.

Well, and cooks yummy.

The whole process of manufacturing such a furnace can be seen in the video.