Arthritis (through the Latin arthrītis “aching joints” from other Greek. Речρθρον “joint”) is a collective designation of diseases (lesions) of joints of inflammatory etiology. A person with arthritis may have difficulty in cases where it is necessary to use physical force. Arthritis is a very common disease that causes painful inflammation and stiffness of the joints. About 26% of women and 18% of men are diagnosed with the disease "arthritis" during their lifetime.

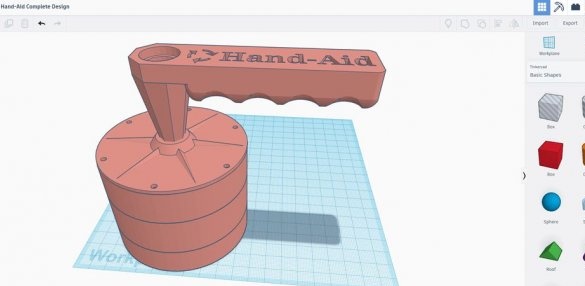

The master wanted to design and do something that would improve the ability of patients with this disease to “turn / twist” everyday objects, since these simple operations for a healthy person cause difficulties for patients.

With the help of his invention, the load on the joints is reduced, and you can easily open / close from water taps to oven handles, from gas plugs to shower taps.

How it works? The spring-loaded rods of the device will take the form of the object to which they are attached. This “manual help” will provide additional leverage that will help reduce pressure on any joints and cartilage, helping to significantly reduce pain.

Tools and materials:

-3D printer;

-Super glue;

- Screws 3.5X80 mm - 6 pcs;

- Threaded rod M4 -120 mm;

- M4 nuts - 2 pcs;

-0.5 mm stainless steel modeling wire;

Step One: Project

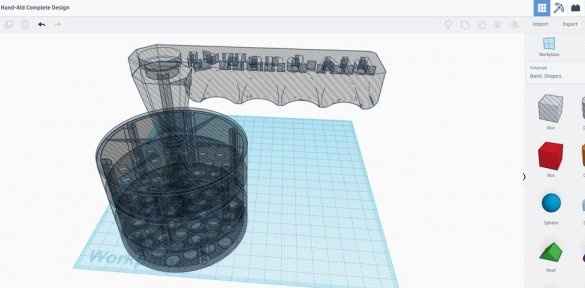

First, the master made sketches of paper, and then moved on to computer processing. The project was developed by the master in the TinkerCad program.

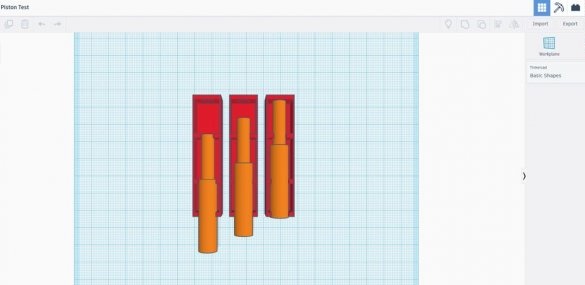

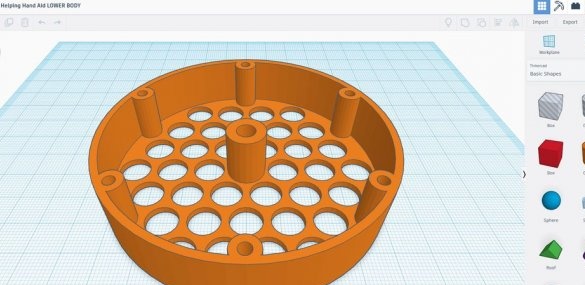

Step Two: Printing Parts

Now you need to print the details on a 3D printer. Links to print files are provided below. Each file, except for the pistons, needs to be printed in one copy. The piston needs 36 pieces. The wizard placed the "Piston x1" file for printing, one at a time, and the "Piston x36" for printing all at once.

Helping Hand Aid LOWER BODY.stl

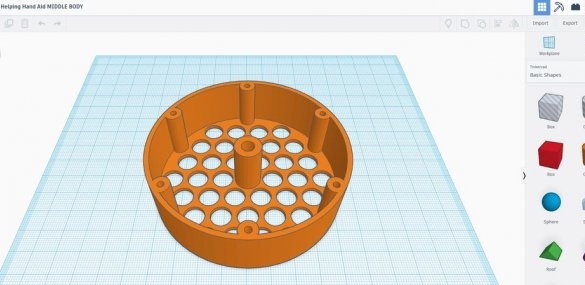

Helping Hand Aid MIDDLE BODY.stl

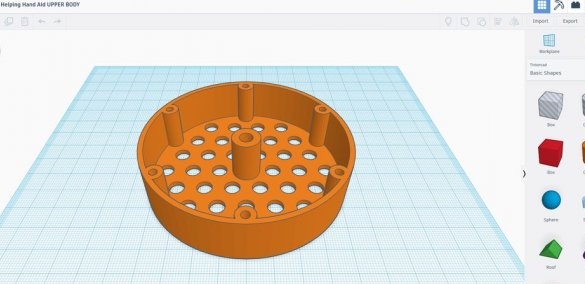

Helping Hand Aid UPPER BODY.stl

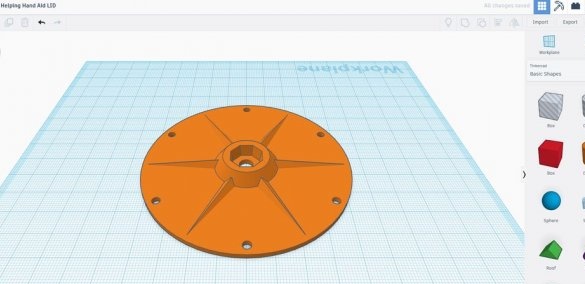

Helping Hand Aid LID.stl

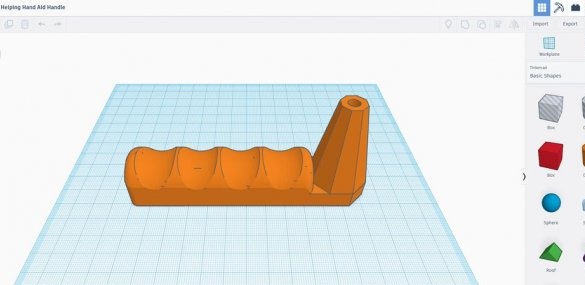

Helping Hand Aid Handle.stl

Piston x1.stl

Piston x36.stl

NUT COVER.stl

PISTON STOPS 36x.stl

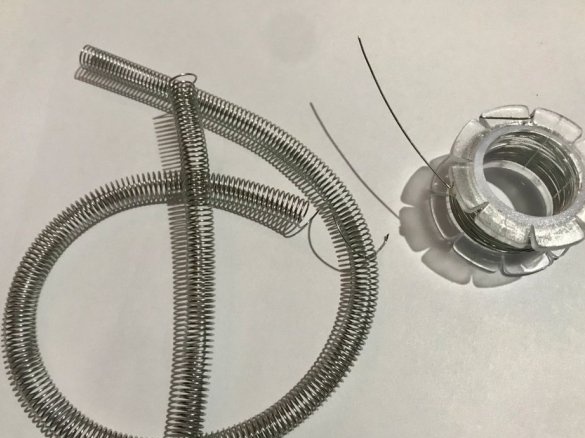

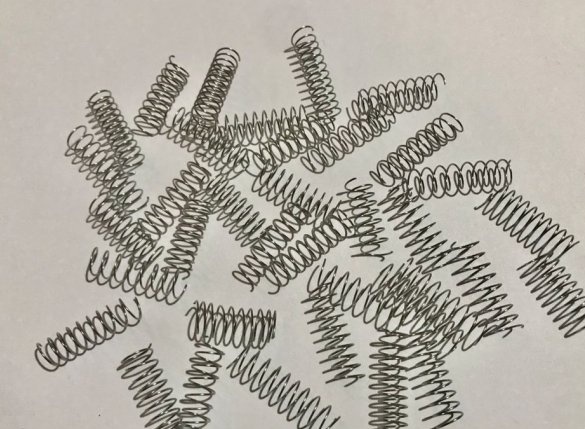

Step Three: Springs

The device needs 36 springs. You can either purchase them, or do it yourself, the main thing is that the diameter of the springs corresponds to the thick side of the fingers.

The master winds the springs independently from the wire for modeling.

Step Four: Build

Now you need to assemble the device. The master polishes the influx on the printed parts. Then glues the lower and middle parts of the body. Installs 36 fingers in the holes. Installs springs on the fingers. From above, it installs another part of the body by passing fingers into the holes.Stoppers adhere to the top of each finger, they will prevent fingers from falling out. Screws the top cover. In the center fixtures there is a hole. A threaded rod must be pulled through it. A nut is screwed on it from below, a handle is mounted on top and fixed with a nut.

All is ready.