This silver pendant the master made a Christmas present to his wife. The pendant was not cast, but turned out from a single piece of metal.

Tools and materials:

-2 mm silver plate;

-0.5 mm silver plated copper wire;

-Sandpaper;

-Varnish;

-Engraver;

-Pliers;

-Capacity with water;

-Retail;

Step One: Template

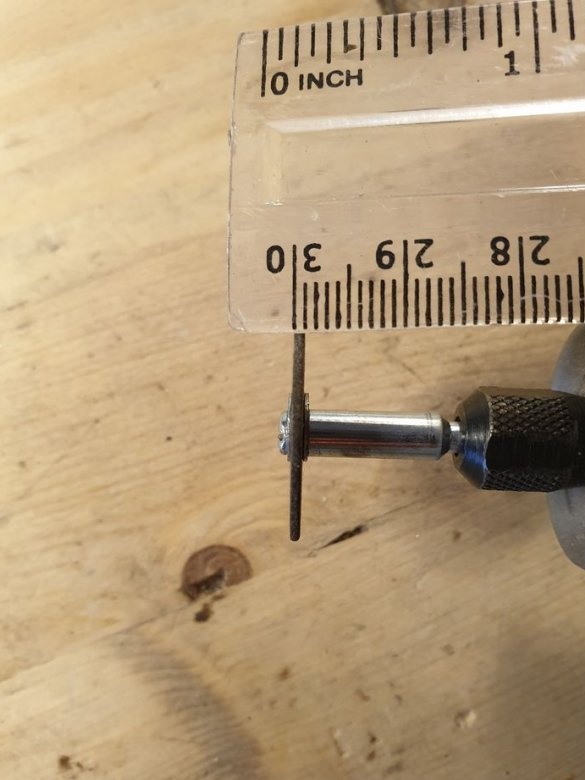

Pendant width 12.5 mm, length 20 mm. The master draws a teardrop shape on the paper, then cuts out the template. Imposes a template on the plate and outlines.

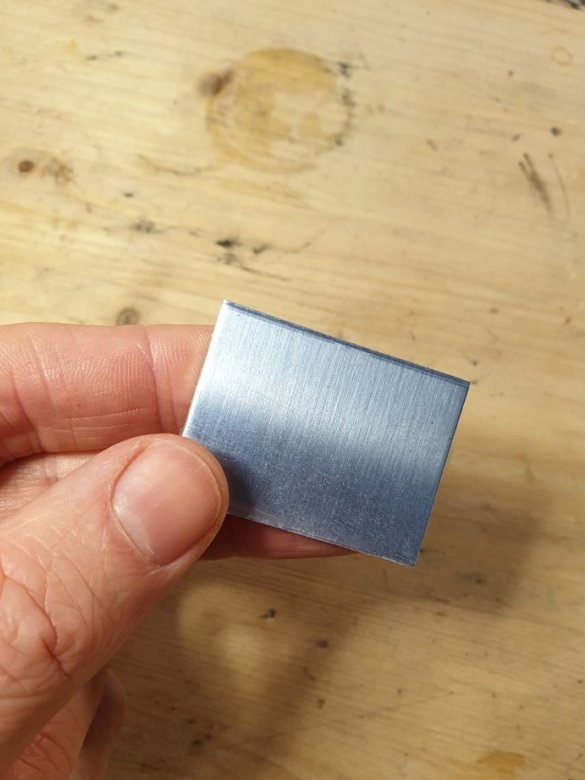

Step Two: Harvesting

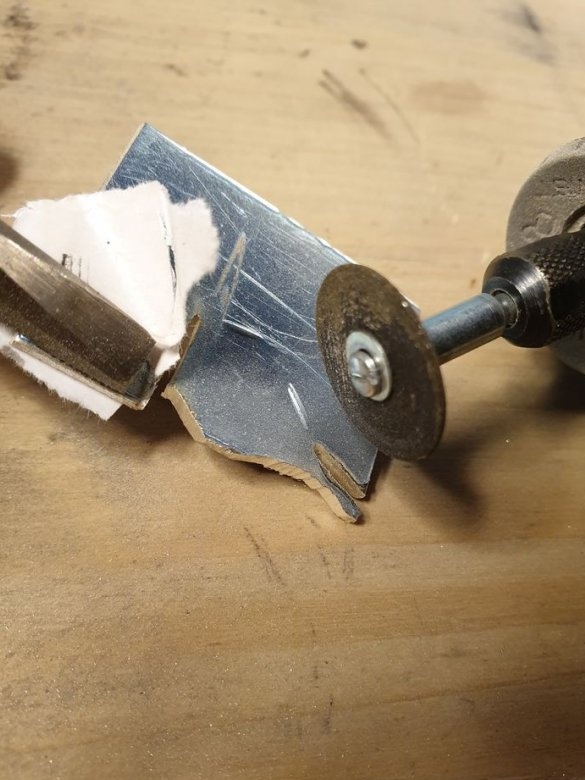

Now you need to cut the workpiece. In order not to scratch the surface, the master pads soft material between the lips of the pliers and the workpiece.

Cut the workpiece.

Step Three: Workpiece Processing

Grinds the workpiece, gives it the desired shape.

When grinding the workpiece uses water.

Step Four: Grinding

Next, you need to grind the product. The master first uses medium sandpaper,

then shallow.

Step Five: Digging

On the tail of the product grinds a recess. It is needed to attach the pendant.

Step Six: Polishing

Next you need to polish the pendant. For polishing, the master uses a polishing disc, rags, paste.

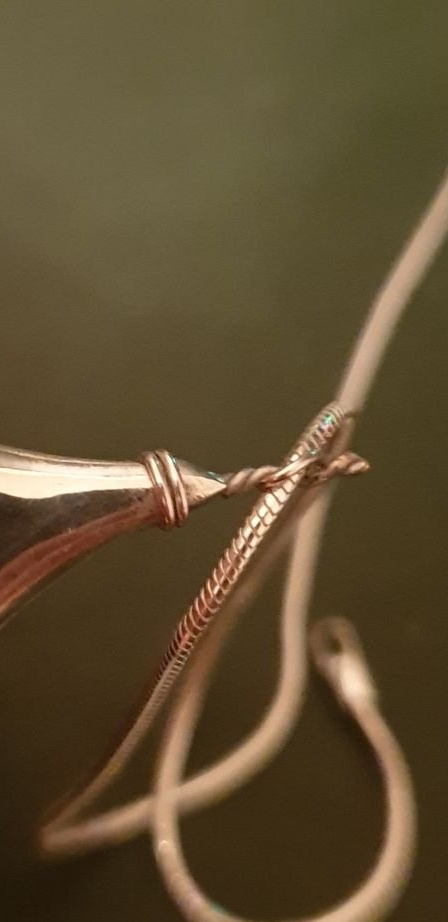

Seventh step: suspension

Then the master polishes and then winds the silver-plated wire around the “tail” of the pendant around the groove.

Makes an eye. The end of the suspension bites and polishes.

Threads a chain through an eye.

All is ready.