In this article, the Master will share with us his experience in the manufacture of electric guitars. The old electric guitar of the master serves as a template and donor. The purpose of this work is the processing of complex forms of wood.

Tools and materials:

-Fibreboard;

MDF;

-Red tree;

-Maple;

-Acrylic;

-Old electric guitar;

Epoxy resin;

-Insulation tape;

- Paint tape;

Step One: Disassembly

As already mentioned, the old electric guitar will serve as a template, and some of its details will be donor for the new guitar. The master takes apart an old guitar.

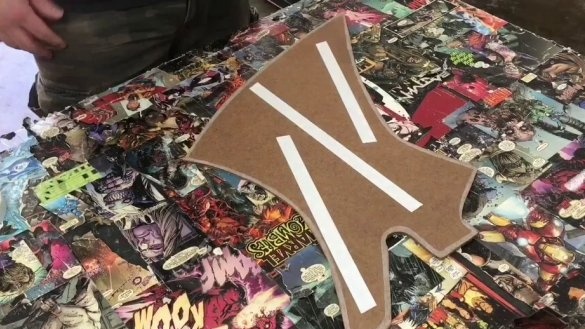

Step Two: Template

The master places the guitar body on the fiberboard and outlines it with a marker. Roughly cuts a pattern.

Glues the template to the body.

On a milling machine, customize the template.

Where metal parts protruded from the body, he turned the material on a grinding machine.

Step Three: Holes

While the master is glued to the guitar body, the master, using the body as a template, drills holes.

Then he peels off the template and, on plexiglass, makes a template for holes and technologically grooves.

Step Four: Centerline

Takes measurements and draws a center line.

Step Five: MDF

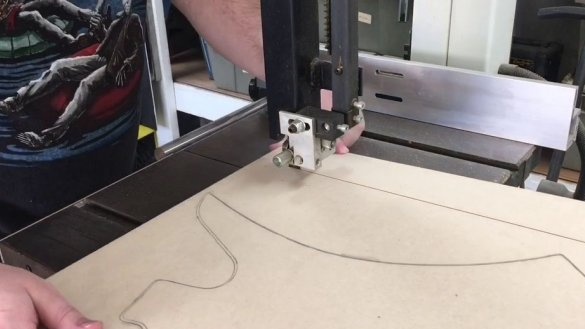

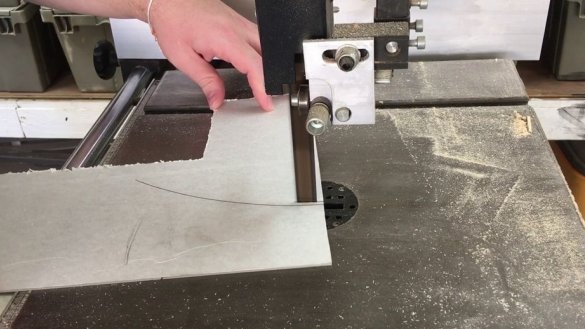

Then the master fixes the template to MDF and outlines it. Cuts MDF.

Secures the template to MDF and processes it on a milling machine. Thus, he cuts three blanks.

Step Six: Gluing

Glues three blanks together.

Before the glue dries, it fixes the workpieces with screws. Removes excess glue.

Seventh step: grinding

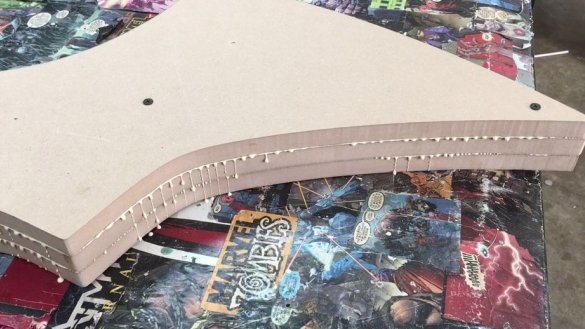

Grinds the workpiece. Wraps with packing tape.

Step Eight: Holes

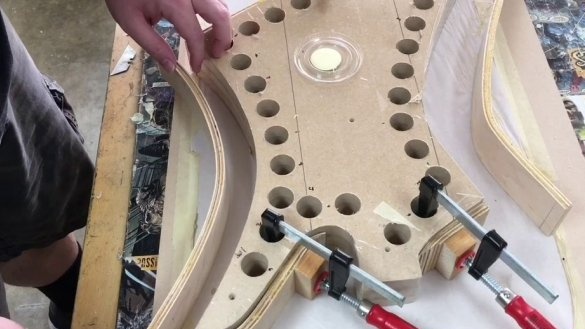

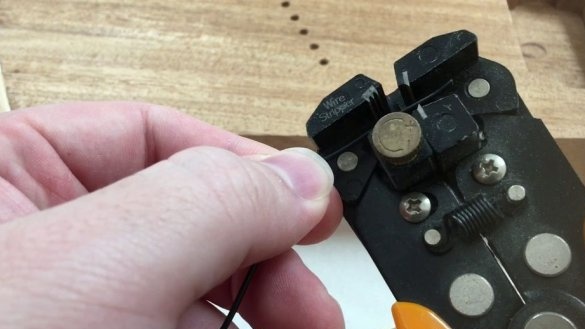

A number of holes are drilled around the perimeter.

Step Nine: The Inside

All that was done earlier is the manufacture of templates for the guitar. Now the master begins to manufacture parts of the case.

From mahogany, the master carves the inside of the case. It is on it that the metal parts of the guitar will be attached.

Drills holes and cuts out a groove for fastening of a signature stamp.

Step Nine: veneer

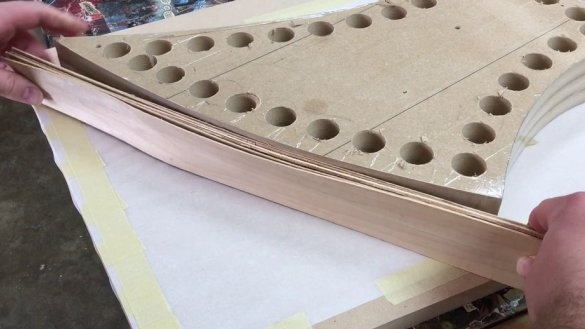

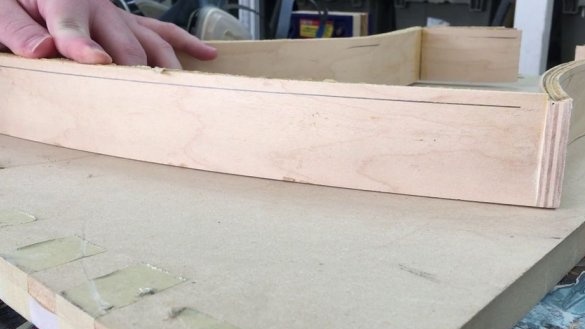

From the veneer, the master will make the outer part of the body. Compresses them with clamps, and then fixes with masking tape. Then marks and cuts the veneer into strips.

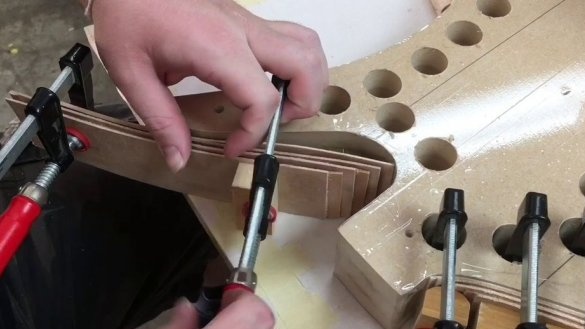

Now from these strips you need to make a body part. The master applies glue to the strips and presses them with clamps to the previously cut template into straight or small radius sections. The glue dries in 24 hours.

On sharp corners, another technology needs to be applied. The master places the veneer strips in a container and boils for 15 minutes. Then takes out the veneer. Now it has become flexible and can be easily squeezed around corners. In this state, the veneer is dry. After drying, it has the shape of a given angle.

The master glues veneer strips. After the glue dries, it polishes the workpiece.

Now all the parts can be glued together.

Step Ten: Housing Assembly

Now you can start assembling the body and guitar. First, the master polishes the parts and adjusts the inside to the outside.

Glues two parts of the body.

Step Eleven: Overlay

From acrylic cuts the pad. Drills in it mounting holes and a hole for the potentiometer.

Step Twelve: Final Assembly

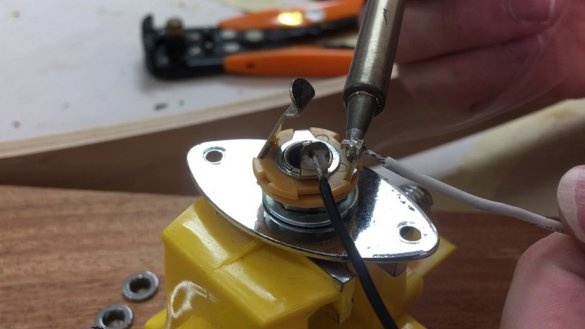

Then the master installs all the accessories and the neck from the old guitar.

Everything is ready, now you can try the guitar at work.