Alexey from the city of Khanty-Mansiysk decided to build all-terrain vehicle models pneumatics using Autoros tires. The all-terrain vehicle is characterized by a rather light construction and compactness, while combining the ability to carry goods. And also this model pneumatics compares favorably with their counterparts with installed bodywork. An all-terrain vehicle should be served at the request of the author for standard purposes, for riding on rough terrain and for fishing / hunting, including in the winter season.

More details about the parts of the mechanisms used in the construction of this model of a pneumatic all-terrain vehicle:

1) Before the construction of this all-terrain vehicle began, the author purchased front gears from VAZ 2123 in the amount of two pieces, they will be used as the front and rear axles of the future all-terrain vehicle.

2) As already mentioned at the beginning of the article, almost new wheels were acquired by AUTOROS and have dimensions of 1220 by 490.

3) The frame will be welded manually from the existing profile pipe.

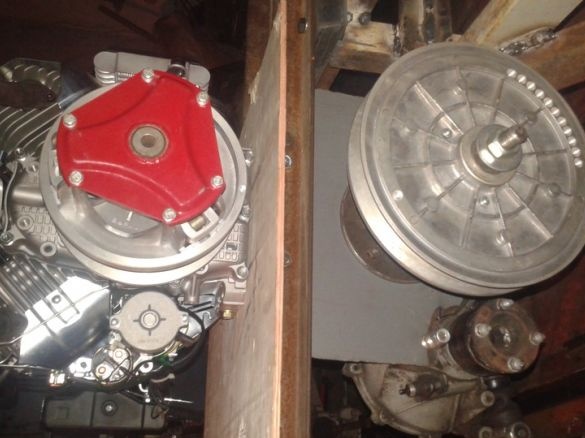

4) The gearbox removed from the VAZ 2109.

5) Lifan internal combustion engine with a capacity of only 22 l / s, it is also important to note that the engine has a variator.

Below will be presented a photo report on the steps of assembling an all-terrain vehicle from scratch.

To begin with, the author decided to start welding the frame, what he eventually learned can be seen below:

There are already visible set bridges and here is the first fitting of wheels:

A more detailed photo of the front axle:

Moreover, one of the design features is that the rotation will be carried out exclusively for the light of the front axle. Why did the author decide to use this method? Everything is quite simple, if you design the turn of both bridges (a biaxial all-terrain vehicle) it does not slightly complicate the design, and also adds weight to the all-terrain vehicle, which is quite critical for the engine of the car. Another important detail is that when turning both axles there is a strong load on the steering gear. Therefore, the author’s decision had the goal not only to facilitate the all-terrain vehicle, but also to add a travel resource and safety margin.

Moreover, as the author himself admitted, he did not see the possibility of installing swivel bipod along the frame, due to the fact that they will likely interfere with the rotation of the wheels, and this is unacceptable.In addition, the suspension does not give the bipod into the frame, it will only work at an angle from the left front wheel to the right rear wheel, and this is definitely not the best option, and in general there are doubts about the operability of such a scheme in practice.

The next step in the assembly, the author decided to fix the wheels on the frame:

And here are the photos of the rear wheels:

A rigid hitch was installed and all four wheels were dressed, additional work was also done on the frame, frame, installation of the steering column and the steering wheel itself:

The shafts were not made by the author, but turned by a professional turner in the factory. That's what came out of it:

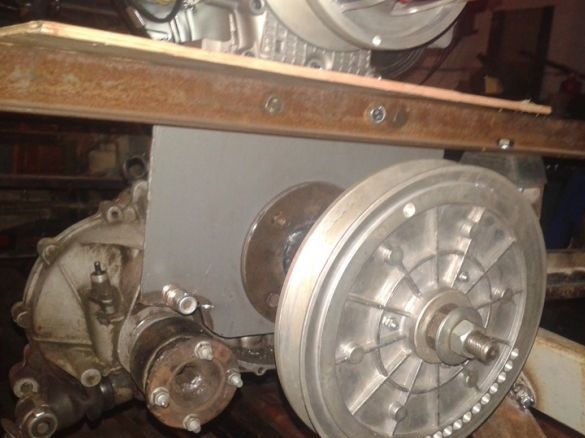

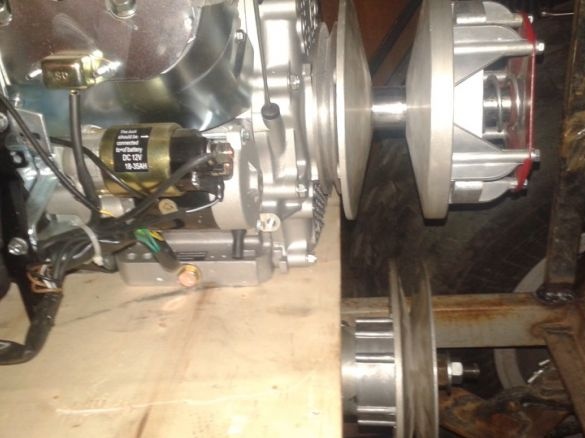

This same shaft was installed gearbox VAZ 2109:

Unfortunately, the installation was not without problems in design features. The distance between the pulleys is 33 centimeters, so I had to look for a belt from an imported snowmobile, since the author had no experience in operating a wider and longer belt than Buranovsky on the Safari variator.

Here is the video of the first exit, the frame is already welded and the main construction works are completed:

View of the all-terrain vehicle after installing the casing and external finishing work:

The first steps of the finished off-road vehicle on wheels AUTOROS:

In mid-April, after the completion and rolling of the all-terrain vehicle was complete, a trip to the lake was carried out along a melted winter road, with a total length of 120 kilometers. The all-terrain vehicle showed its best side when driving on all types of surfaces, including snow, swamp, ice.

After the indicated exit, a screw lock with a preload of 5 was installed in the front axle. During riding along the river, a breakdown occurred: the cover of the front gearbox and then the rear gearbox burst too.

After eliminating the damage, another hunting trip was carried out. It included 70 kilometers of track on a rigid hitch, about half a kilometer along the floodplain, after which the cover of the rear gearbox again gave slack and cracked. As a result, it was decided not to make long trips and the rear universal joint was removed, but after 70 meters the case and the front gear cracked. so gearboxes are a weak link in this design and need rework.

if anyone is interested in how the author got to the garage with similar problems being 70 kilometers from home, he had to go all the way in reverse.

Actually, to improve the design, the author bought bridges from Oise, has already revised them and is just waiting for parts from the turner to install them and solve structural problems with gearboxes.

The author of the all-terrain vehicle Alexei from Khanty-Mansiysk under the nickname riazan.