Interesting model karakata with the design of the tipping frame and all-wheel drive on the OI-25 tires. the weight of the all-terrain vehicle was about 450 kilograms. All terrain vehicle initially designed for two people and freight, but if you wish, you can take passengers into the back, as there is a specialized bench.

Materials and assemblies used in the construction of this all-terrain vehicle:

1) Tires Oi-25

2) pipe profile size 50x50x2

3) drive from vaz 2110

4) Lifan engine 13 hp

5) drive a large pulley from the VAZ 2109

6) the hub of the vaz 2108

7) steering rack from frets viburnum

8) steering column from vaz 2105

9) brake disc from vaz 2108

10) hand brake from vaz 2108

11) clutch cylinder from vaz 2105

12) clutch cable from vaz 2110

Let us consider in more detail the stages of construction of an all-terrain vehicle, as well as the main components of its structures.

To begin with, the author decided to weld the all-terrain vehicle frame from a profile pipe measuring 50 by 50 by 2 mm.

In order to peel the oi-25 tires, the author even made a homemade winch, a complete peeling took a whole month and a half.

The fracture node was made on the principle of k-700.

Then the author began to manufacture all-terrain vehicle drives. The design of the VAZ 2110 was taken as the basis, since it is made of a pipe and is easily subjected to welding work. The sliding fork of the driveshaft from a classic vase was also used.

The seat of the plug was machined to the diameter of the drive pipe. The drive itself was cut to the desired size, and then a plug was installed in it and the whole structure was subjected to welding. Thus, one side was inserted into the grenade of the gearbox, and the flange was screwed to the front axle of the all-terrain vehicle. The second drive, respectively, goes to the second grenade and flange to the site of the fracture of the all-terrain vehicle frames.

Then the author began work on the transmission of an all-terrain vehicle.

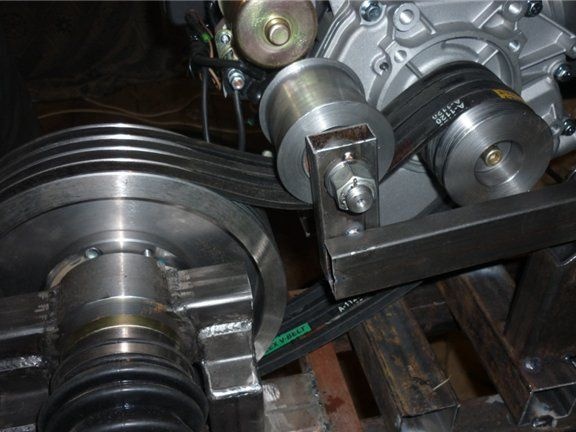

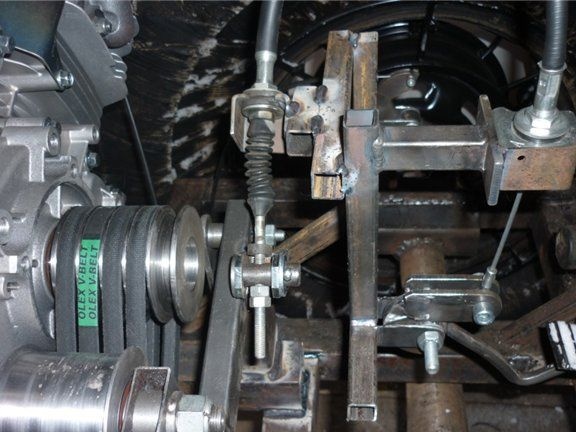

After that, the author mounted the frame on the wheels and set the 13-hp lifan engine. A belt clutch was also created. The drive of the large pulley from the VAZ 2109 was taken along with external grenades, one grenade being modified so that it could enter the input shaft of the gearbox.

More details about the work on the grenade: it was printed out and the separator with balls was removed, after which the spline shank was cut off, and a spline sleeve was cut from the clutch disc. then a hole was made for the size of the sleeve.After that, the sleeve was installed in a grenade and subjected to welding work. welding was carried out according to the principle of how the frame fracture assembly is welded.

For the manufacture of the driven pulley, a hub from vases 2108, a wheel bearing and a retaining ring for this bearing were taken. A new support box was machined for this bearing and the support legs were welded to the bearing itself. Then the details come together. The pulley itself is put on the wheel of the machine and fastened with wheel bolts.

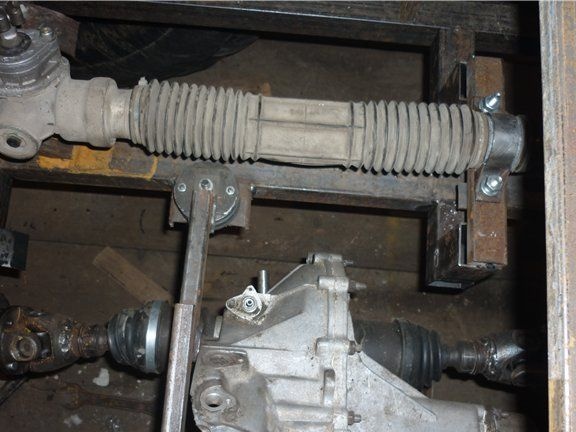

Then the steering rack was installed from the fret of viburnum and the steering column itself from the VAZ 2105. steering cardans were interconnected.

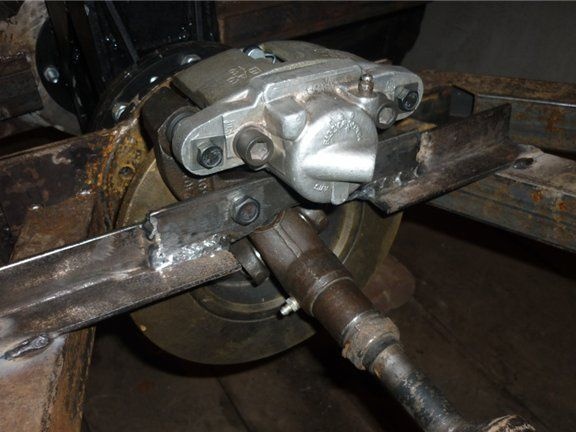

Brakes were installed on the driveshaft. On the rear axle shaft there is a disk from vaz 2108 and a support.

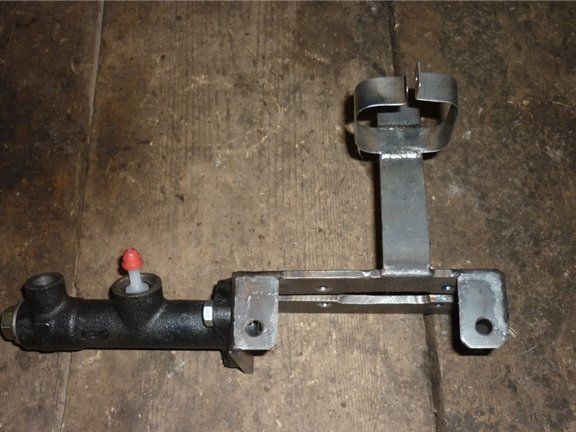

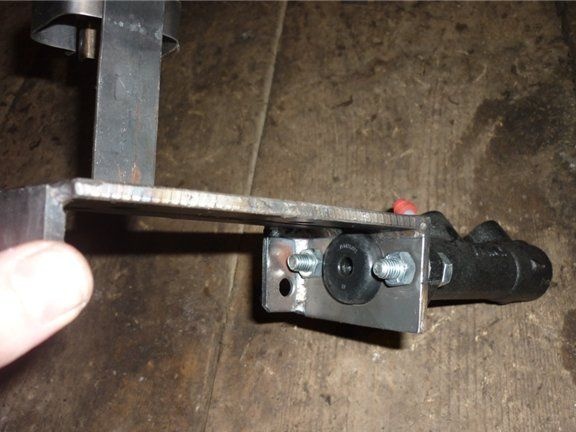

For the manufacture of a brake machine, a hand brake from vaz 2108 and a clutch master cylinder with a tank from vaz 2105 were taken, the bracket was made by the author himself.

The curtain was installed standard from the vase, but shortened for convenience.

Other photos of all-terrain vehicle designs:

After which the author proceeded to test the all-terrain vehicle. When traveling in the snow with a depth just above the knee, the all-terrain vehicle weighs itself well. The transmission works flawlessly, there is not even slippage of the belt clutch, the power reserve and traction of the all-terrain vehicle are felt. The wheels are also made soundly as tests have shown. No tire rotation even with visible wheel loads. The maximum speed of the all-terrain vehicle in fourth gear is 20 kilometers per hour, but there is still fifth gear.

Here you can see in more detail the design of the clutch drive of an all-terrain vehicle, the basis of which is taken from the clutch cable from the VAZ 2110.

After testing, the author began to consider the possible blocking of the differential of bridges. But since the chance of damaging the structure under serious loads may increase, as well as when both axles are blocked, the radius of rotation of the all-terrain vehicle and the force required on the steering wheel will significantly increase, it was decided to block the differential only on the rear axle of the all-terrain vehicle. Then proceed to a new series of tests.

Meanwhile, the casing was installed on the all-terrain vehicle.

The engine compartment of the all-terrain vehicle was modernized.

A car generator and a tire inflation compressor, which works directly from the engine, were also installed. The generator was used from VAZ 2110. The generator had to be installed, since the standard was only 35 watts and this was not enough. A battery was also installed that will power all major lighting devices. The compressor was delivered just like that, but inflating the tires in 8 minutes in the field will not hurt. In addition, if desired and replacing the hose, the compressor can also suck out air from the tire, which will allow you to adjust the tire pressure on various difficult sections of the track without much effort. Also, an air intake grill was added in front of the all-terrain vehicle, and the compressor itself is fixed to the frame, which serves as a tensioner.

And this is how an all-terrain vehicle is transported over long distances:

The author of the all-terrain vehicle: Artyom with the nickname "Artyom12" on from the city of Verkhnyaya Salda.