All terrain vehicle with side turn function, differential. the transmission is built on chains. Before the construction of the all-terrain vehicle began, the author planned to keep within only 250 thousand rubles, but as a result he spent twice as much. the reason for the costs was the author’s desire to develop more functionality and reliability of the all-terrain vehicle.

For the construction of an all-terrain vehicle, the following elements, materials and assemblies were required:

1) OKA internal combustion engine with an injector.

2) a gearbox for the same engine with a welded differential.

3) the steering column from the Niva

4) The bridge from Oise

5) wheels of the brand Arktiktras 1300 to 700 to 21

6) stars of 40 and 12 teeth.

7) muffler suzuki

8) resonator from matiz

Consider the stages of construction of an all-terrain vehicle:

This all-terrain vehicle is the first self-assembled author. Due to the lack of experience in the construction, there was a serious approach to each element of the structure, with the study of documentation and practice. During the assembly process, various difficulties arose, which the author managed to cope with. The problems faced by the author will be described below.

To begin with, the author made a plan by which he was going to build an all-terrain vehicle, and also highlighted the main problems that he might face.

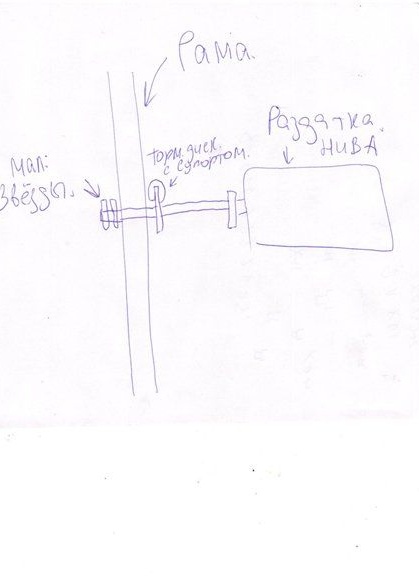

Planned to do side-turn an all-terrain vehicle with a Chinese Oka engine complete with a gearbox for it, through a Niva transfer case. accordingly, such a scheme raised questions, since the author did not have assembly experience.

It was necessary to decide exactly how to brew the differential on the gearbox while making an exit to the Niva transfer case. then you need to create a transition from the transfer case to sprockets and brake discs, respectively.

One of the options to do this is to use the shaft from the Niva gearbox and connect it to the Oka gearbox.

After all the necessary parts were purchased, including the whole Niva, which was safely disassembled for parts.

But the decision to switch to asterisks through the frame is not quite simple:

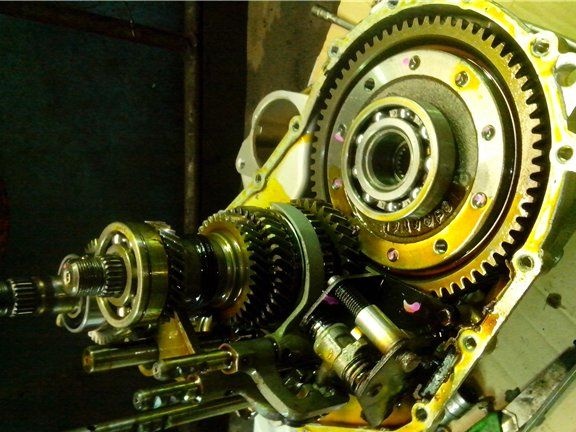

The gearbox was disassembled:

using argon welding, the differential was brewed, and the box was assembled back:

After performing theoretical calculations, the approximate all-terrain vehicle speed in fifth gear was established, it will be about 35 kilometers per hour.

Then the author began welding the frame:

Approximate installation of the engine, axles and transfer case:

The shaft was used by the drive in a fret grant, and sent to the coupling, in general terms this should not be difficult, but otherwise you will have to work a turner to shorten and fit all the details.

The author shortened the bridge from Oise, and decided to install brake discs to the hubs. Also, a support from the Niva will be welded to the bridge, and an adapter is bolted to the axle shaft. Stars used in an adapter for 12 teeth.

there were no changes to the driveshaft, as it is native and, accordingly, approaches the bridge.

Specifically, a bridge from UAZ 3151 was taken, a pipe was welded to it. The axle mounts were cut off, and a hole with a diameter of 30 was made, through which the axis was pulled in and then fixed by welding.

The bearing from the VAZ 2108 is attached to the frame and pillow of the transfer case, and then there is an exit for a pair of 12 dental stars.

The bridge was recreated:

The following adapters are made:

Gear shifting is implemented in a similar way:

Installed driver's seat:

In this form, the first test of the all-terrain vehicle was made.

After the first test of the all-terrain vehicle, the correct operation of the side-turn mechanism was revealed, the reason for this was the brake disc, or rather, the insufficient force applied to it. The solution was found with the installation of a second caliper. With heavy loads on the all-terrain vehicle, its overload, another important detail was revealed. Not the reliability of the steering column mount, which was subsequently redone. chain jumps were eliminated with chain tensioners.

The width of the frame was 85 cm. To create it, a seamless pipe with dimensions of 76 by 3.5 was used.

It was originally machined on a lathe, and then welded using argon welding.

The transfer case was fixed, as well as it was brought to the edge of the frame, it is necessary that in the future there was the possibility of installing the propeller without altering the chassis.

The fuel tank was installed:

Bought wheels from one of the craftsmen:

Control levers installed:

Used radiator from vaz 2108 with a fan:

Catalyst 11116 Involved:

Then the author began to collect the hubs:

Here is the finished frame:

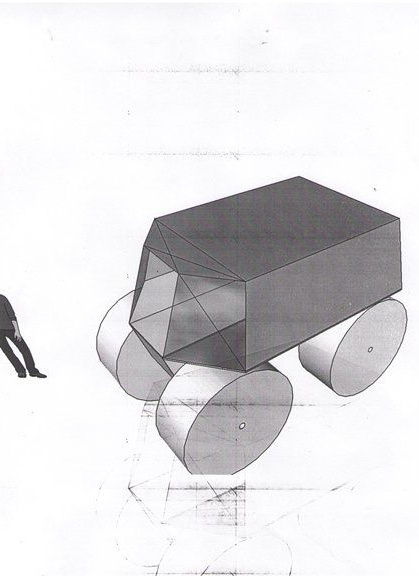

Outlines for the appearance of the casing of an all-terrain vehicle:

Hubs with an axis diameter of 65 mm are made:

A silencer from Suzuki is installed, as well as a resonator from Matiz. Thanks to this decision, it will be possible to drop deep into the forests without scaring game.

This is how the axes were made:

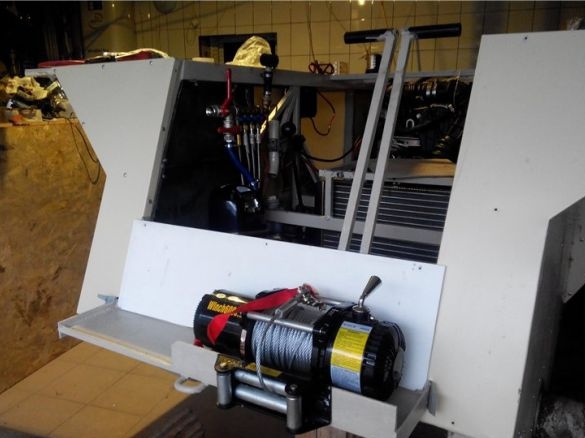

Site photo:

Tires for an all-terrain vehicle ordered:

The differential was removed and disassembled to find a solution to the problems with the rotation:

Turning problems

But as already mentioned. nevertheless, it was decided to fix through the brake cylinders, and the installation of additional calipers.

Dimensions of the all-terrain vehicle:

width 240 cm

length 200 cm

Since the chain dangled and could bump into the tooth of a star during rotation, the author took up two main issues: the brake force for easier rotation, as well as the installation of chain tensioners.

The liter engine pays off, 50 liters. from. quite enough for a similar car.

The result was two calipers on each side of the all-terrain vehicle, after such an upgrade, turning the all-terrain vehicle became easy and smooth without requiring effort.

Accelerates to 35 km \ h in fifth gear. you can start immediately with the fifth.

Below is a video where you can evaluate the driving capabilities of an all-terrain vehicle:

Expansion tank installed:

implemented swapping through the hub:

Winch delivered:

Here are photos of chain tensioners:

After their installation, the chain does not jump or ring. the all-terrain vehicle itself works quite quietly without vibration.

Tests of the finished machine were carried out. On them, the author found out that the engine is one of the best places in the design of the all-terrain vehicle, thanks to it it is possible to turn around in fifth gear, even hints of unstable operation did not arise.

All-terrain vehicle author: Victor from the city of Moscow with the nickname vitos