I already wrote an article on how to make a parabolic solar furnace based on a satellite dish. Such a furnace showed excellent performance and efficiency. However, not everyone has an unnecessary satellite dish, and buying it specifically for the manufacture of a solar furnace is very expensive. Therefore, this article will discuss the manufacture of a parabolic solar furnace based on foil and cardboard.

Materials that the author used to create this model of a solar furnace:

1) corrugated cardboard

2) stationery knife

3) glue

4) polished foil

5) bolts m4 20 mm

6) wide washers

7) fabric

8) wire

Consider as much as possible the plan for creating a parabolic solar furnace, as well as the main distinguishing features of this model.

And so, the author decided to make a solar oven in the form of a satellite dish, using cardboard as the main material.

To be more precise, we used corrugated cardboard from ordinary cardboard boxes. Therefore, in order for all the elements to be sufficiently even and durable, the author fastened two such sheets with glue so that the waves of the corrugated board of each sheet were perpendicular to each other.

To simplify the manufacture of a solar furnace, the author made several schemes, according to which construction.

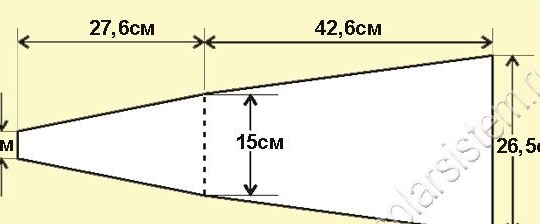

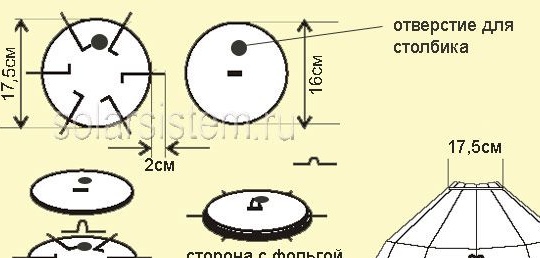

The author decided to create a parabola of 12 parts of the same size. According to the dimensions shown in the diagrams, the future solar furnace will be an area of about 0.8 square meters. However, you can enlarge the elements on a scale thus obtaining a large surface area of the parabolic solar furnace, which in turn will increase the maximum temperature that this furnace can create.

In order to speed up the process of cutting elements of the solar furnace from sheets of cardboard, the author drew one element and made it template. Further, this template segment was simply applied to the cardboard, and with the help of a clerical knife, all other segments were cut out.

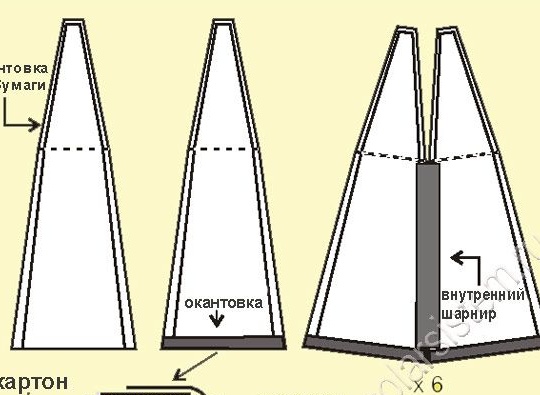

To protect and strengthen the elements of the solar furnace, the author made their edging. To do this, a 5 cm wide strip of thick paper was glued to each element along the edges. Also, the elements were interconnected using a glued strip of fabric, which will act as a swivel. Such a connection will allow folding the solar furnace, if necessary, for its storage or movement.

Since the author preferred to use “accordion” for the addition of the oven folding, the strips of fabric between the segments were attached alternately from the front to the back. At the same time, the author left a gap between each element 2-3 mm wide, so the edges of the elements would not experience additional load when folding the solar furnace.

After all the elements were connected together, the author received the necessary parabola. The next step was foil gluing on its inner surface. The author used precisely polished foil, since it has a sufficiently large reflective effect. Self-adhesive wallpaper with a mirror surface is sold in stores, which are also excellent for gluing the inner surface of a solar furnace.

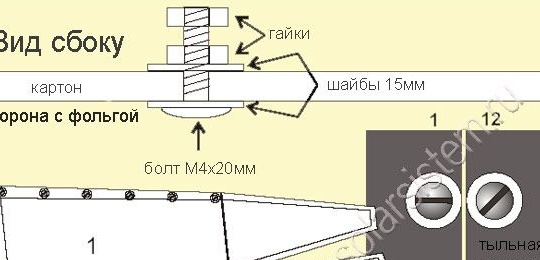

To fix the elements in the form of a parabola, the author screwed several bolts to the first and twelfth segments of the solar furnace. The author used 20 mm M4 bolts and wide washers for their reliable fixation, as they will be screwed into cardboard.

At the convergence point of the elements of the solar furnace, the author made a round plane of plywood. This plane acts as a stub, as well as a fixator for a narrow part of the elements of the solar furnace. For this, the author used a wire that will fasten the elements to this stub.

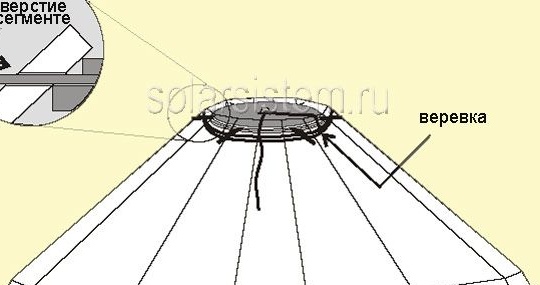

All this is perfectly shown in the schematic pictures below:

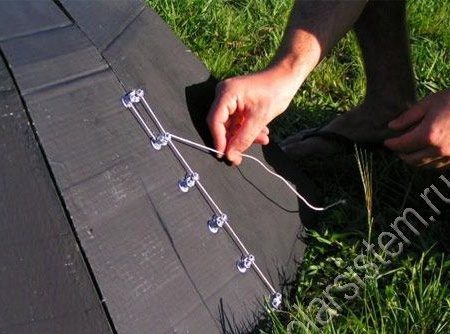

As can be seen from this diagram, the wire is inserted into the hole in each segment through one, after which all segments at the base are wrapped with a rope and securely fixed.

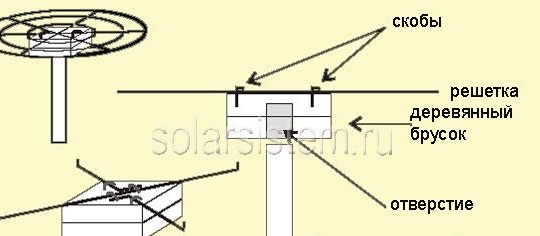

In order to make a stand on which the pan will be installed, the author used a wooden block and a metal grill.

Thus, the tilt angle of the solar furnace itself and the location of the pan in it, which directly depends on the position of the sun at the horizon level, can be easily adjusted.

Since the solar furnace mainly consists of cardboard and foil, it is quite light, so when installing it must be fixed so that it is not blown away by the wind. Fixation of the solar furnace occurs using stretch marks, and in order to prevent the geometry of the furnace from suffering from these stretch marks, the author pulls the parabola with a rope.

[center]

Surprisingly, in clear weather, the cooking speed, according to the author, is twice as high as when using a gas stove. Other advantages of this stove is that it is very cheap to manufacture, since it does not require expensive materials. Thanks to the folding design, this solar furnace is very easy to transport and store, and besides, it is very light, since its main component is cardboard.

In conclusion, the author recalls that the cooking time when using solar ovens depends on a large number of observed conditions. The main factors affecting the speed of cooking are the intensity of sunlight, the amount and size of the food being cooked, and the ability to properly monitor the direction of the oven relative to the sun. Therefore, if you have little experience in cooking on a solar oven, the author advises starting with simple dishes like rice or baked potatoes. It is also important not to forget to move the stove towards the sun approximately every 30-60 minutes during cooking.