If you want to make an original lamp do it yourself With virtually no cost, this instruction is for you. To make such a lamp, wood waste will be needed, the author used plywood and small boards from plywood. It was necessary to buy here only some electrical parts, and also the costs go to glue.

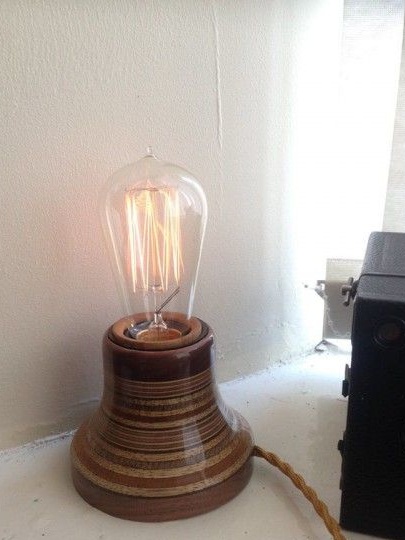

As for me, this style fits perfectly in steampunk.

Materials and tools for homemade:

Materials:

- fork;

- glue for gluing wood;

- to finish the wood will need super-glue or polishing glue;

- lamp holder;

- network dimmer;

- lamp (the author liked the lamp of Addison);

- a piece of cable (or you can just twist two wires).

Instruments:

- a tool for cutting wood, and an act for turning;

- high-quality clamp;

- drill and drill;

- screwdriver and device to remove insulation (our man does it with a knife

When processing wood, a lot of dust is formed, which is harmful to health if inhaled, apart from glue particles. So work must be carried out in a respirator or at least a protective mask.

The manufacturing process of the lamp:

Step one. We assemble the lamp housing

You can choose any shape of the lamp housing, this is just an example for manufacturing. The base is made of several layers of boards, plywood or other material. The author used walnut boards and plywood for these purposes. They need to be folded so that the intersection of the structure occurs. All layers are carefully lubricated with glue, and then tightly clamped with a clamp or in a vice until the glue completely dries.

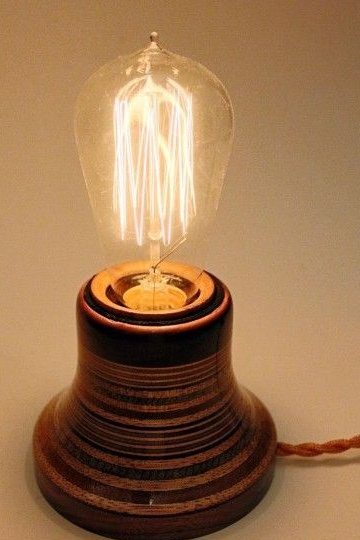

The author used different types of plywood and boards to get strips on the lamp. Thanks to these strips, it was decided to name the Zebra lamp.

Step Two Primary rough processing of the basis

Immediately after the glue dries, the workpiece can be given its original rough shape. In addition, a tooth will still need to be formed on the workpiece, thanks to which it will be mounted in the chuck.

Step Three Shape the workpiece

Now the workpiece can be clamped in the lathe chuck, this can be done thanks to the tooth formed in the step earlier.

Before forming the profile of the base of the lamp, the author decided to make a recess in it for installing the lamp holder. Thanks to this recess, it will be easier to form the main profile, since it will act as a guide.To make this deepening, you must first drill the workpiece with a drill, and then select the desired amount of material using a semicircular bit.

At the end of this stage, the home-made was processed with sandpaper, and the tree is a little shaded.

Step Four We drill a hole for the cable and polish the workpiece

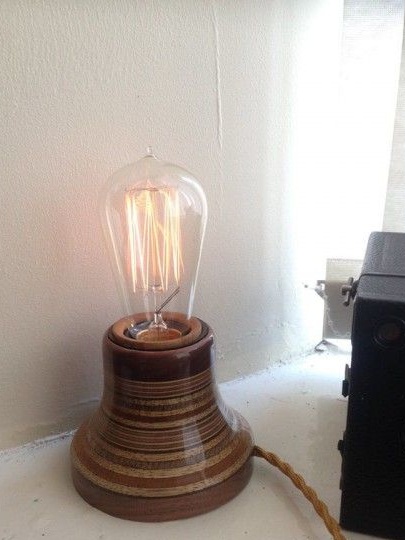

To make it convenient to lead the cable into the lamp, the author drills a hole in it, it is located on the side at the bottom of the lamp base. This hole should converge with the channel that was drilled along in the previous step.

To drill a workpiece, the author blocked the machine using an indexing system, and then used a manual electric drill.

The next step was the external treatment of the base. It must be properly treated with sandpaper, gradually reducing the grain size from coarse to fine. You need to achieve good smoothness over the entire area. Well, then the workpiece can be polished. For polishing, the author bought inexpensive cyanoacrylic glue and applied it to a workpiece with a paper towel. When the glue is completely dry, the workpiece needs to be slightly leveled with sandpaper, and then polished to a shine.

Step Five We remove the tooth for fastening in the machine

Now you need to carefully cut the tooth from the base of the lamp. To do this, the workpiece unfolds back to front and is clamped through the inside. Now the tooth can be cut. It is advisable to get the base as even as possible. In conclusion, it can be sanded with sandpaper.

Step Six The final stage of assembly

The final step will be the connection of all electrical equipment, and this is just a cartridge, cable and plug. We pass the wire through the center and fasten the plug to the end to connect to the outlet. We connect the bulb holder to the other end. The wire must be well insulated to avoid short circuits. Well, then it remains only to screw in the lamp and insert the plug into the outlet, the lamp should turn on.

For ease of use, such a lamp would be nice to equip it with a switch. However, the switch can be installed directly on the wire.

That's all, the lamp is ready. As can be noted, everything is robbed very quickly, not taking into account processing on a lathe. But this is just an example, the basis can be thought up and another, which will be easier to manufacture.