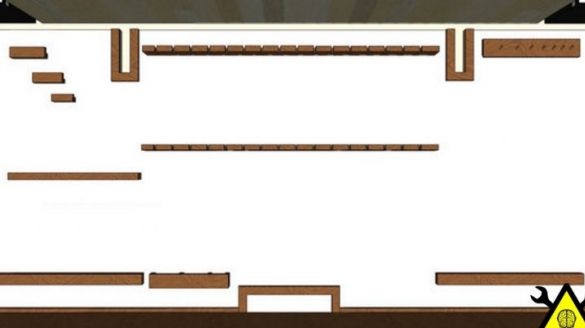

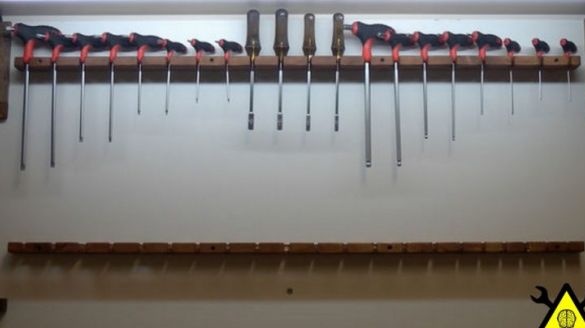

The author took a pair of similar holders for hexagonal keys with a T-shaped handle, several ends. screwdrivers, rasps, etc.

He laid out all the tools in order to find out the length of the rails.

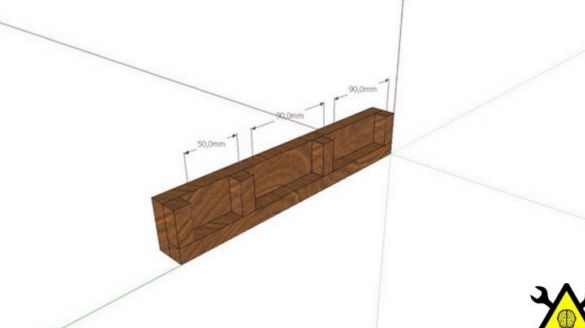

As you see in the photo, he marks the places under the landing holes and applies the marking using a square.

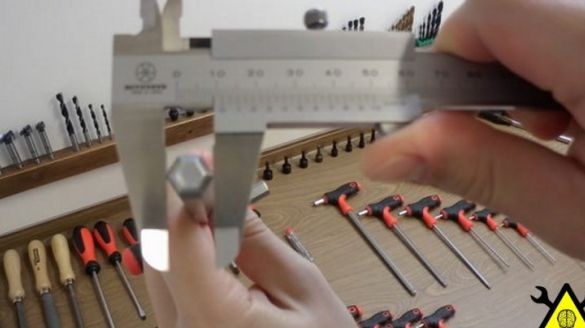

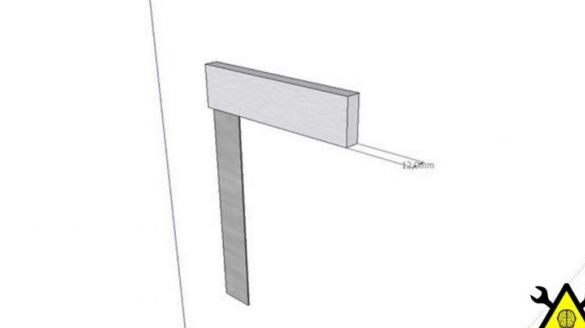

The diameter of all handles is measured and 1 mm is added to the original result.

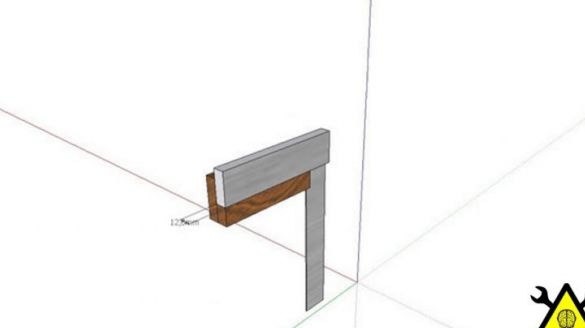

Let's move on to the drilling machine. We drill a Forstner drill deaf. openings on one second thickness of a lath.

In the case of the author, the thickness of the slats was 2cm.

Then he measures the diameter of the slave. parts, and also adds 1 mm to the original total.

Then he drills through center holes in previously drilled holes.

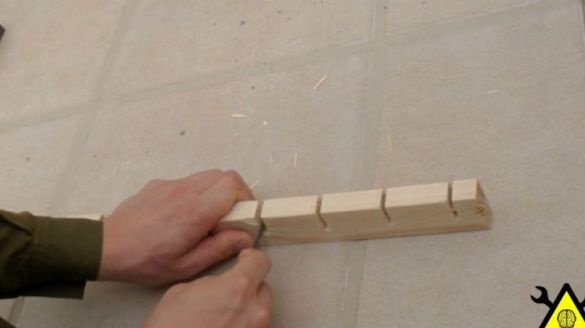

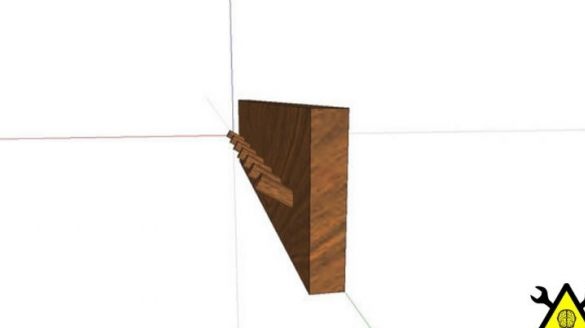

We turn the rail over and draw 2 identical lines to each hole.

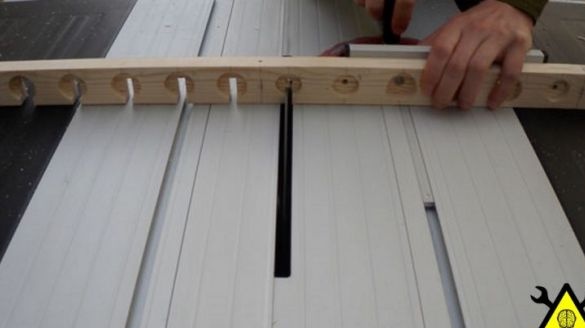

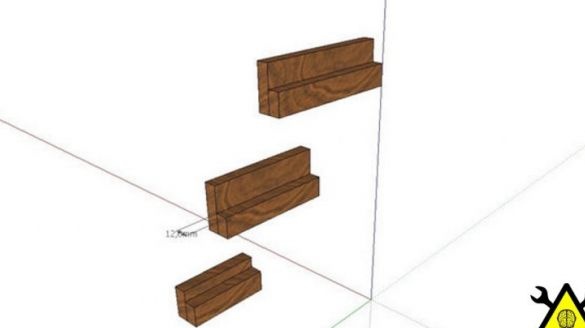

We adjust the desired height of the knife blade and begin to cut out the areas that were marked before.

He then polishes the slats on each side.

For thin section. special rails were used soft sandpaper.

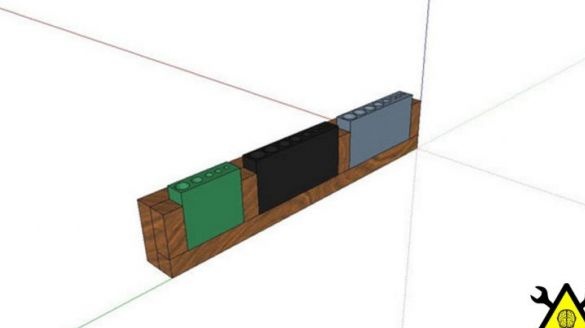

We expand openings for ease of installation of all necessary tools. Expanding not too much!

After finishing grinding, the author takes up the painting.

After painting, you need to leave everything to dry for about a day and then install support on the shield, which will be attached to the wall.

Parsing the whole mess!

To install metal corners, the author makes L-shaped shelves.

Then he measures the dimensions of the base of the drill, then drills special corresponding grooves in the bar. Putting it all together!

To connect the crowns, he takes the fillet, drills a row of holes or holes into it at an angle of 45 degrees and fixes the dowels in them.

How do you like this article? I hope you enjoyed it. Thank you so much for your attention!