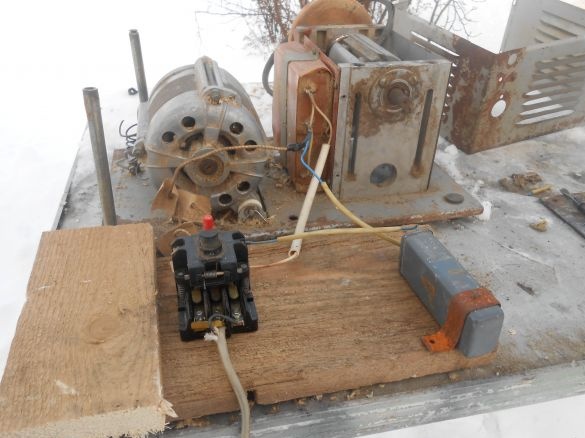

The weather is lovely today! Frosty 10 degrees and the sun. I decided to recharge myself with vitamin D, and for one, sort out the woodworking machine inherited from my father.

To him, more gadgets go for turning work. At one time there was a gorgeous machine. And a plane and a circular and emery, and of course a wood lathe.

That's how he looked in his youth

With such characteristics

The desktop woodworking machine UBDN-1 is a compact desktop device for processing softwood and hardwood lumber.

The woodworking machine UBDN-1 is designed to perform the following operations:

• cutting lumber, not more than 25 mm thick

• jointing of lumber, not more than 100 mm wide

• drilling holes with a diameter of not more than 6 mm

• milling grooves with a width of not more than 6 mm

• turning of workpieces with a diameter of not more than 70 mm

• tool sharpening

In his last working days he was very slow, when processing boards, he constantly stopped, as if there was not enough strength. At launch, I wanted to help him accelerate.

Let's see what's inside

Belt drive from the engine to the jointer shaft, which sits on two support bearings. Yes, the strap lives on ...

And here is the culprit of the malfunction

The common wire fell off the start toggle switch.

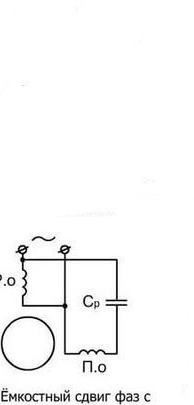

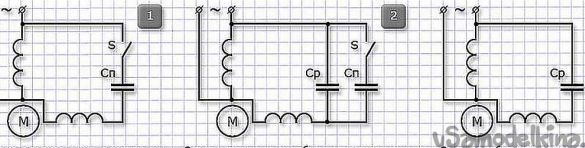

The machine uses a connection diagram of a motor with a capacitive phase shift with a working capacitor. Engine DVA 71-2ukhl4, 370W, 50HZ, 220V, 2826 rpm.

Since the asynchronous motor decided to redo the motor connection diagram on the machine. On the circuit with two capacitors, working and starting, control through a button like PNVS. Of course, you can apply a circuit with a starting and working capacitor without the PNVS button, and on the toggle switch, but with it it is somehow more comfortable ...

Here is the actual scheme:

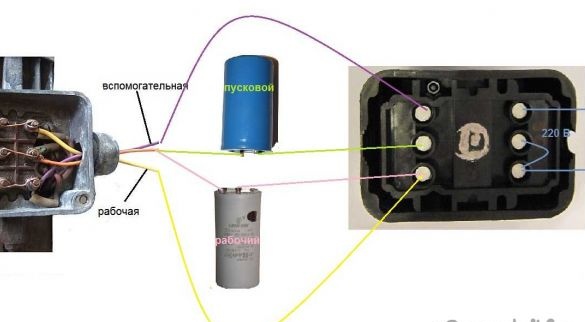

We analyze the miracle of Soviet industry

And we connect according to the scheme, as it were, by hinged installation to check the operability of the scheme.Complying with safety and labor regulations.

We check. Everything works, starting the engine immediately without buildup, keeps the speed according to the passport ...

We do a revision of the bearings, lubricate and assemble.

And then it starts to get dark, vitamin D ends.

The whole machine is back in operation, in the summer we will operate, so to speak we test the innovation. Have a nice weekend and good luck, it's time to go home.