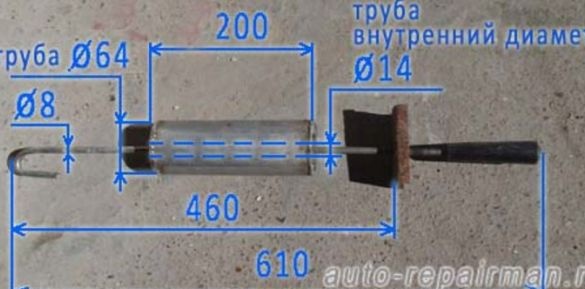

According to the principle in such a hammer: a rod on which on one side there is a hook, handle, stopper, striker. We take the hammer in one hand, and the second we set the hammer in striking the stopper. The author took from a sheet metal a pair of not large pieces of the same diameter, and one piece of metal thicker, two pieces of pipe one larger, the second smaller, but slightly longer than the first and even the handle. The author does not indicate the sizes in the text; your sizes may differ from the sizes of the author. The dimensions of the author in the picture above.

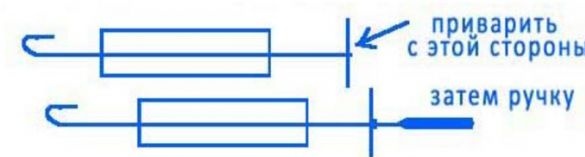

You need to make a circle of metal, its size is equal to the diameter of the pipe, which is larger. In it it is necessary to drill a hole equal to the smaller pipe diameter. Next, the smaller pipe needs to be welded as in the picture.

Explanation from the author: first, he cut a square the size of a little larger than the size of the pipe, which is larger, then made a hole for the pipe which is smaller and welded it, and then turned it into a circle of the desired size. The picture is another option. Everyone has the right to do their own thing.

The author put on a large piece of pipe on the resulting blank and scalded it. Further, the author made another puck, exactly the same as at the beginning.

Then he cut a smaller pipe, with a margin for welding left 2-3 mm. The picture shows the cut line.

Then he filled the void with dry sand. I put the finished second washer on top and scald everything.

The result was a striker.

At the next stage, the author took: metal for the stopper, a handle and a bar. The author cut the bar with a margin for a hook bend.

The stopper must be thicker of metal so that the stopper does not bend from the impact of the striker. The author took not fat, but he, however, in the form of a bracket.

The handle can be used for anything that fits (or you can just weld a small tube.)

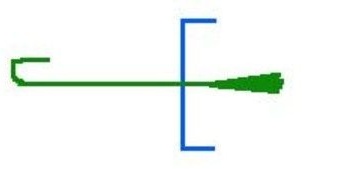

He hooked one edge of the bar, put on the striker, and put on the stopper on the second edge and boiled from the side of the handle. The handle was also welded here (all welding should be on the side where the handle is, but not on the side where the hammer is.) This is the author’s hammer.

The author has welded the washers and is going to straighten the body element with a tool that he made himself.