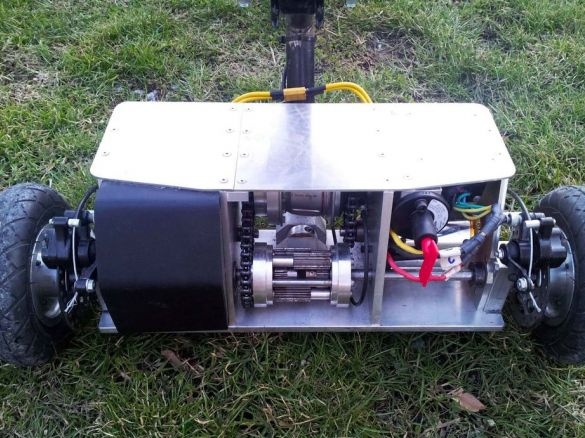

The tricycle made by the Master has an eight-speed gearbox and a brushless motor. Tricycle speeds up to 65 km / h. Each of the rear wheels is equipped with a set of disc brakes, which are actuated by a two-stroke brake lever on the steering wheel. Steering is very similar to bike or motorcycle. In addition to the steering wheel turning the front wheel, the front half of the tricycle frame also tilts to the sides. Inclined movement allows you to quickly and confidently rotate, which would not be possible if the connection was rigid.

Let's watch a video review of the tricycle.

To make the tricycle, the master needed the following

Materials and tools:

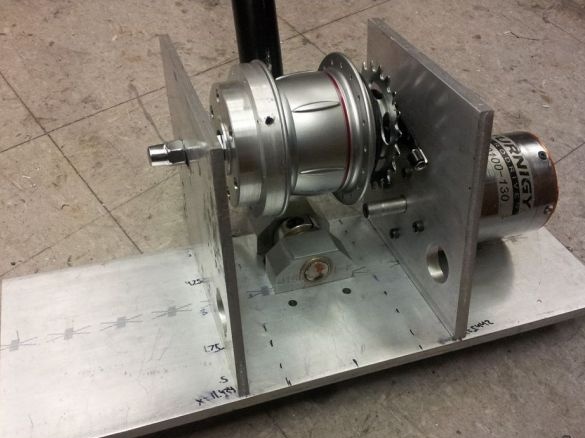

Brushless motor Turnigy C80100-130;

-Transmission;

-Differential;

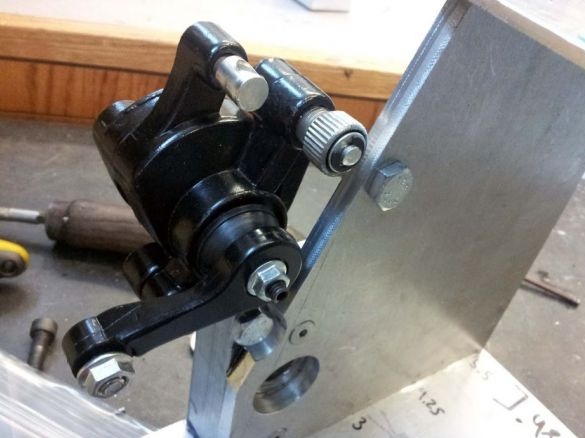

-Disk brakes;

-Wheels;

- fork with a bicycle;

-Welding machine;

-Pipe metal;

-Bronze bushings;

- Aluminum billets (bars, rods, etc.);

-Drilling machine;

-Bandsaw machine;

-Metal rods;

-Bearings;

-Stars;

-Gears;

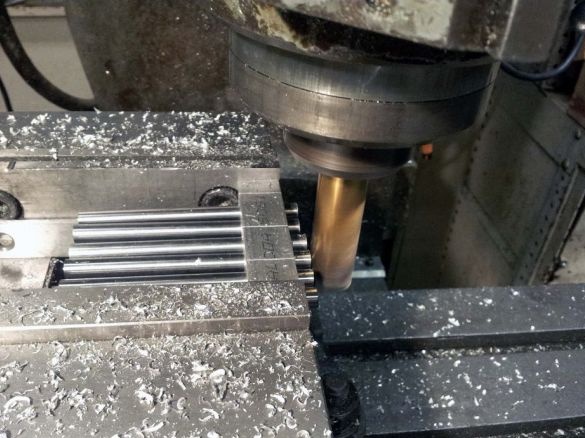

-Turning and milling machines;

-Fasteners;

-Bicycle seat;

Epoxy resin;

Sander;

-Chain;

-Soldering iron;

-Pliers;

-Fuse;

-Switch;

-Dampers;

Step One: Front Fork

The first step, the master redid the plug for the installation of new wheels.

Step Two: Frame

Made a tricycle frame from a pipe.

Step Three: Steering Mount

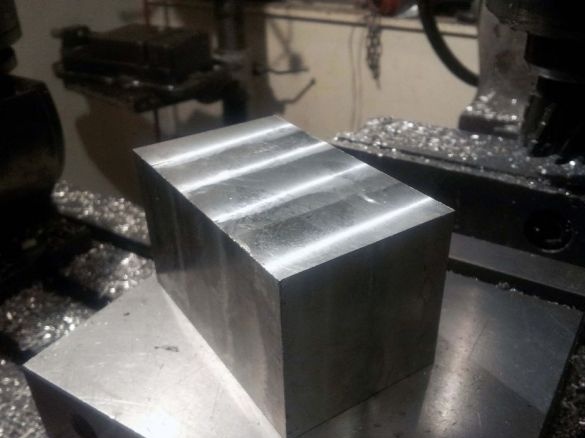

The steering mount can be bought at the store, but the author made it himself from aluminum.

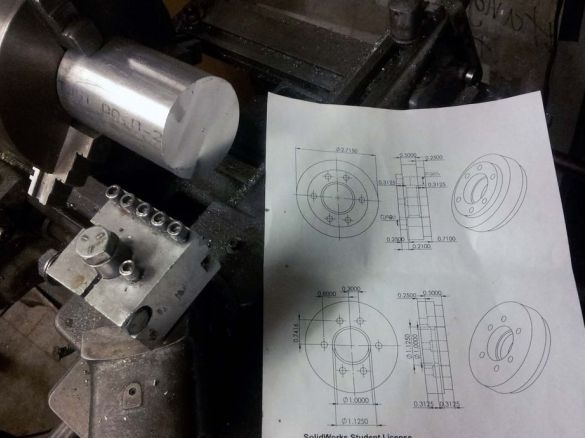

Step Four: Gearbox

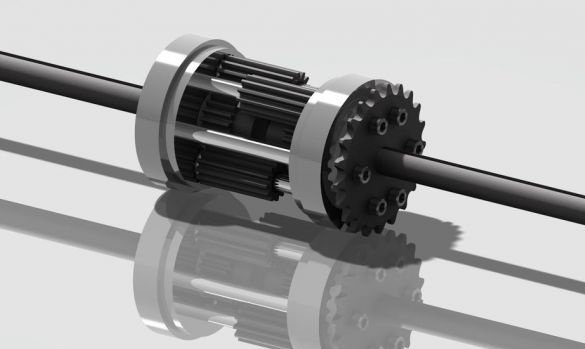

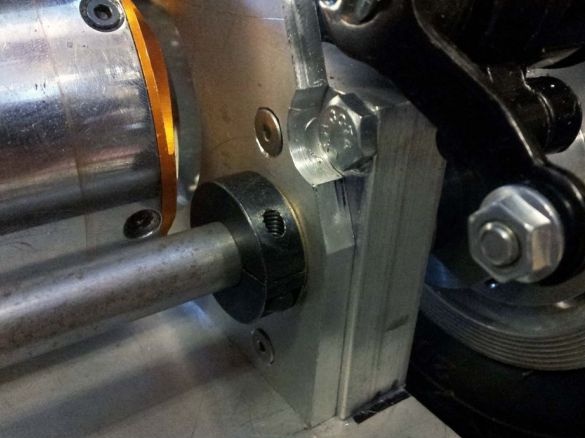

Shimano's planetary gearbox has eight speeds and is designed to be mounted on the rear wheel of a bicycle. Such a box is traditionally controlled by a handle on the steering wheel. For his homemade the master had to redo the box. The master installed another sprocket on the box.

Step Five: Differential

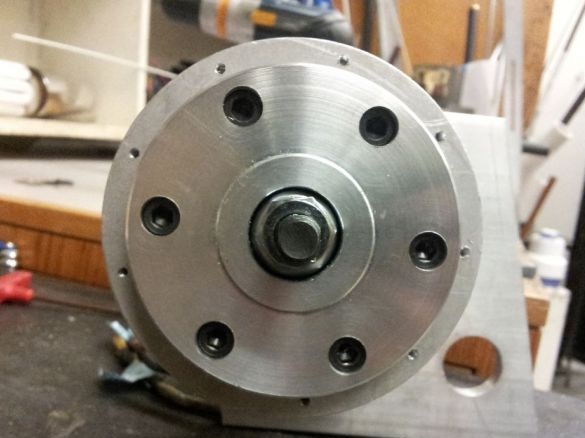

The master made the differential himself. The master turned the covers on a lathe. Installed bearings and shafts. In the gear set bronze bushings. I put gears on the shafts. Set the second cover.

Step Six: Swivel

The front of the frame may slightly tilt relative to the rear. This design simplifies tricycle management. For turning, the master makes an arm with a shaft and a bronze bushing. The bracket is fixed on the platform. A shaft connects the front of the frame to the back. Also installs shock absorbers between the frames.

Seventh step: back

The back of the frame is made of aluminum sheet. Four sheets are vertically attached to the platform. Top closed with another sheet. Almost all electrical and mechanical parts are installed in the inside. Aluminum blocks with bearings are installed on the sides of the platform, they bear the main load from the wheels.

Step Eight: Wheels

The foreman installed the front wheel from the scooter unchanged. At the rear, I replaced the bearings and made a mount for disc brakes.

Step Nine: Seat

Welded to the frame mount for the seat. The master took the seat from the old bicycle. Removed the upper skin. Strengthened the bolts. Screwed.

Step Ten: Brakes

Disc tricycle brakes. Located on both rear wheels. The brakes are controlled by the handle on the steering wheel.

Step Eleven: Small Details

The engine, gearbox and differential are connected via a chain. The distance between the box and the engine is small, so the master did not put a chain tensioner between them. A tensioner is installed between the gearbox and the differential. The master installed bronze thrust washers on the bearings. An aluminum tube was fixed on the frame to support the legs. Also, the master had to change the engine shaft.

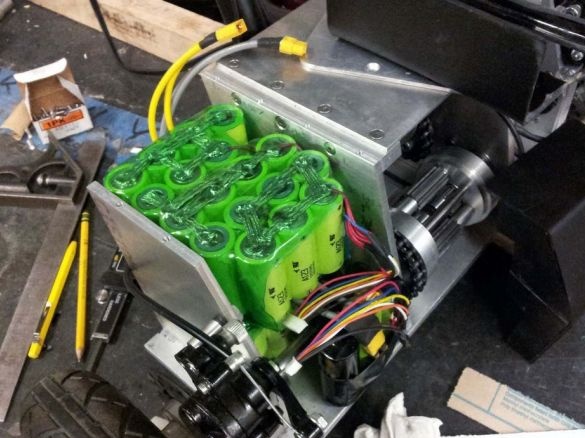

Step Twelve: Batteries

The master used 36 A123 Systems 26650 batteries as a source of electricity. The batteries were mounted according to the 12S3P scheme (blocks of three batteries connected in parallel, then 12 blocks connected in series). According to the master, this is about 300 Wat / hour. At peak load, batteries can produce up to 14256 watts, with normal 8316 watts. For batteries, the master made an acrylic case. The engine runs through the Kelly KBS48121 controller. The control knob is on the steering wheel. A 100A fuse and circuit breaker are installed between the battery and the controller. The controller has a programming function and the master has reduced the maximum current to 90%.

The electric scooter is ready.