Over time, any master has a problem storing the tool. There are more and more tools, and less storage space. And, in the future, if you do not take care of its storage, the workshop will resemble the Augean stables, the order in which only Hercules can restore order. So the Master decided to organize a place to store his instrument.

Tools and materials:

-Circular Saw;

- Guide for a circular saw;

-A circular saw;

-Plywood;

-Measuring tape;

-Pencil;

-Sandpaper;

-Level;

-Nailing gun;

-Fasteners;

- Joiner's glue;

-A screwdriver;

-Miter saw;

-Gon;

Step One: Suspensions

To fix the shelves on the wall, the master decided to use the so-called "French suspension". A rail with an oblique cut is mounted on the wall. A rack with an oblique cut is also attached to the shelf. Then the shelf is put on the rail section to section.

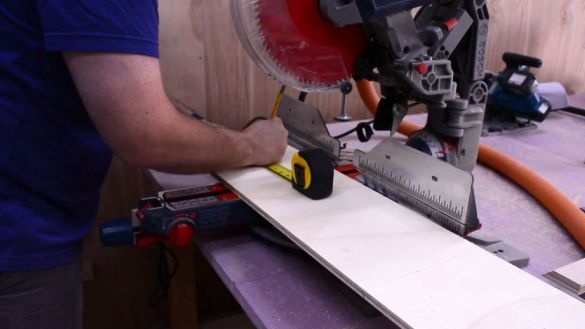

On a plywood sheet makes markup. Cuts a sheet according to a marking.

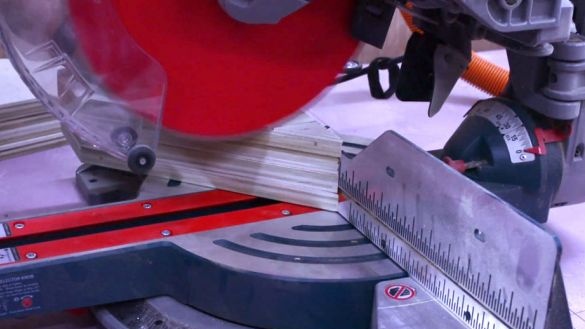

Cuts strips into two parts. The angle of cut is 45 degrees.

Fastens the hangers to the wall. For fixing uses glue and screws. When installing suspensions, they must be leveled with a level.

Step two: shelf for large clamps

Further, the master makes several types of shelves for different tools.

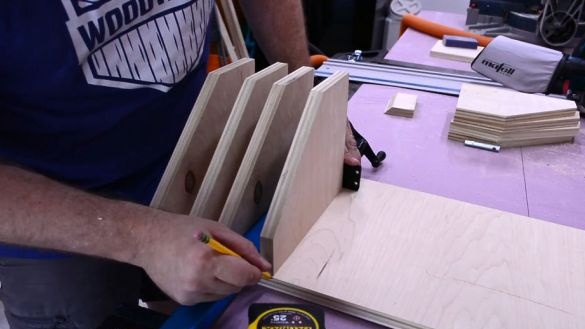

Measures and cuts workpieces.

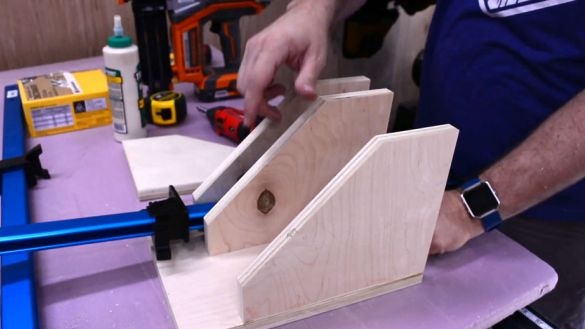

Collects shelves. Fixes parts to glue and, from the back, screws.

On the back, secures the bar with a slanting neckline.

Sets the shelf to the suspension. A tool hangs on a shelf.

Step Three: Shelf for Medium Clips

By the same principle, makes a shelf for medium clamps.

Tightens the suspension and hangs the shelf.

Step Four: Small Clamp Shelf

Now that the process is set up, the master optimizes manufacturing and cuts out several parts together. Then also collects the shelf.

Tightens the suspension and hangs the shelf.

Now in the workshop, order and clamps do not wallow throughout the workshop.

The whole process of making a storage place can be seen in the video.