Hello everyone, I propose to consider a simple adapt for crushing branches. This will be especially useful when leaving the territory, caring for the garden and so on. The eternal question arises, where to put all these endless branches. Now they can be easily and simply turned into firewood. In this manual, we will look at how to make the main crushing unit. To make a car, you will need another engine, materials for the frame and other little things.

List of materials and tools that the author used:

Material List:

- strong thick sheet steel for the manufacture of the frame;

- two bearings with housings;

- steel beam (a working shaft is made of it);

- strong sheet steel (for knives);

- bolts (for mounting bearings and knives);

- paint.

Tool List:

- welding machine;

- grinder;

- a drilling machine or drill;

- tap for threading;

- nozzle on the grinder for metal cleaning;

- a vise.

Manufacturing process homemade:

Step one. Production of a working shaft

The working shaft must be strong, since the loads will be considerable. Its author made on a lathe from a steel "bar." The central part should be rectangular, this will fix the knives here. If you do not have a lathe, you can turn to any turner, the task is quite simple.

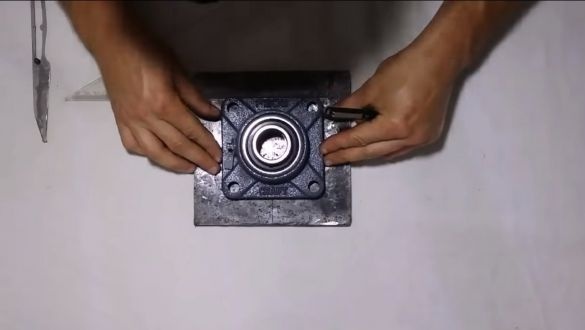

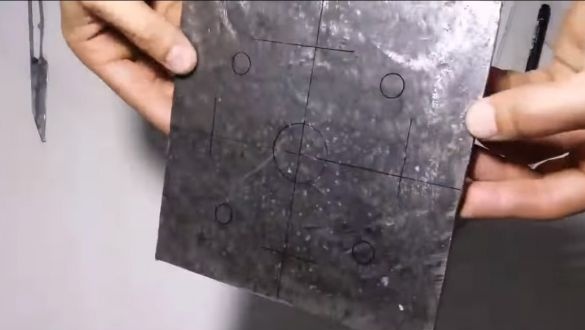

Step Two Brackets for bearings

Bearing brackets are part of the frame. Here we need strong sheet steel, the most strong. Cut two squares and outline the places for the holes. We drill holes and cut the threads, the author fastens the bearings with bolts. Next, you need to make holes for the shaft. At first, the author wanted to drill them, but this turned out to be problematic, since the metal is quite thick. As a result, four holes were drilled, and the author cut a square hole with a grinder.

Step Three Finalization of the working shaft

We drill holes in the working shaft and cut the threads. Knives here will also be attached with bolts.

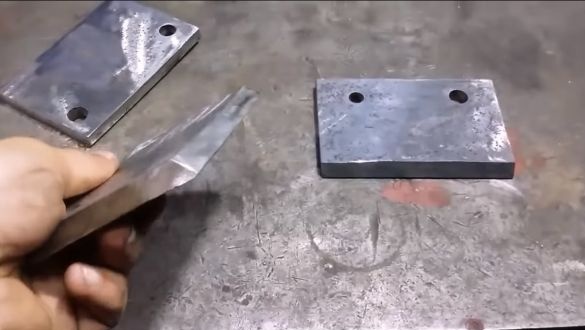

Step Four Production and installation of knives

For the manufacture of knives you will need strong steel and it is advisable to use a metal that can be hardened. Then there will be no chipping marks on it and you won’t need to sharpen knives often. We cut four knives from sheet steel and sharpen. That's all, it remains to drill holes and screw the knives to the working shaft. We install a grover under the bolts so that they do not unwind from vibration.

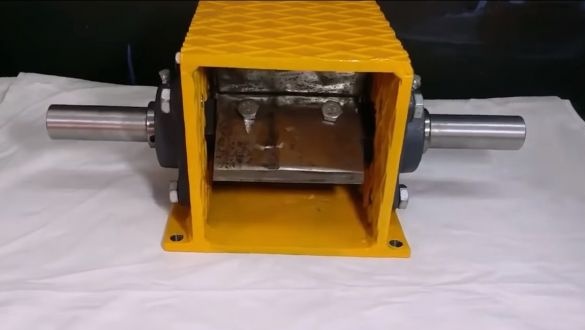

Step Five Putting the device together

To assemble the device you will need two more steel plates. The largest will be the base, in it you need to drill holes in the corners for mounting. Well, weld the entire structure as tightly as possible.

That's all, now the car can only be painted so that the product looks beautiful and does not rust.

That's all, the project is over. I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat it.