Good day to all. With this article, I want to start talking about my modeling tools. Perhaps they will interest not only modelers, but also other lovers of "little things." To make this fixtures It will not take much effort and material costs.

So from the materials we need:

1. Nail clippers (purchased at the Fix Price store for 77 rubles)

2. “Lamb” M5

3. Washer ø5 mm inner diameter

4. A piece of steel wire ø5 mm (I took from the hook of the trading rack)

A little tool too:

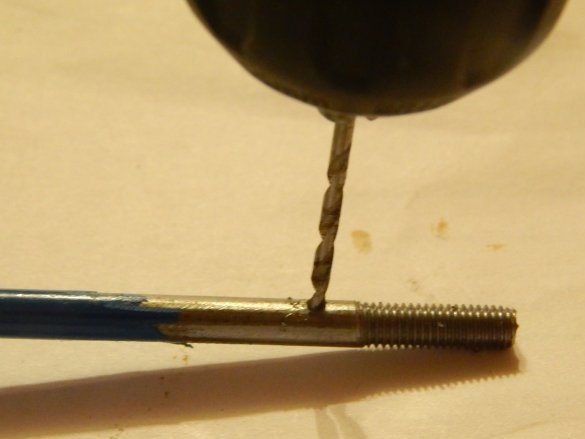

1. Drill, drill ø2.5 mm

2. Hacksaw

3. Flat file.

4. Lerka M5

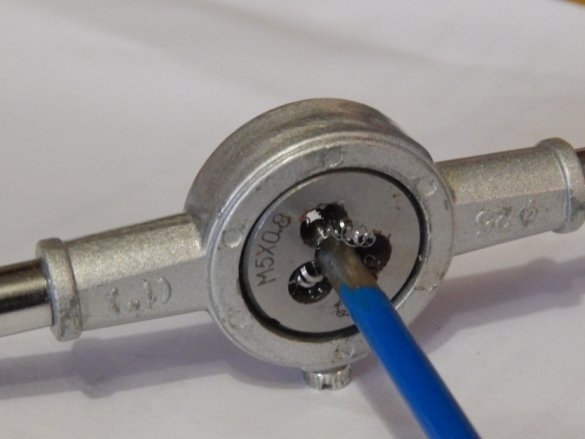

Of all the prepared materials, I needed only the M5 lamb and the washer. I will not clog the article with unnecessary photos, I will just show what happened when using a simple M5 bolt:

The upper hairpin is made of hook wire of a trading rack.

At first I just wanted to make a miniature vise with a “wing” clip

And to use the lever as needed, but then it turned out that the lever in the folded position perfectly copes with the stopper function.

I sharpened the cutting jaws to a width of about two millimeters, I consider it sufficient to clamp small parts.

Raised the question of threading the wire, but there were no problems with this. As a lubricant, I used ordinary pork fat, even according to the stories of the master at the school, I remember how he said that for cutting threads fat is even better than sulfofresol.

I drilled the bar without incident, using the same lubricant.

I cut a groove with an ordinary hacksaw

And then processed with a flat file

To compare the dimensions, I bring a snapshot of a handmade jewelry vice. They are certainly good, but quick clamping in them does not work. In my device, the part can be clamped both with the “lamb” and with a lever, the clamping force of which is also regulated by the “lamb”.

Let me give you an example - cutting a groove on a yoke for fastening a guy. Since there are a lot of them on the model of a sailboat, a quick clamp greatly facilitates the work.The rigging wiring blocks are processed in the same way.

That's all for now, I hope my article will be useful to someone, until we meet again.