To make such homemade.

The author took an old metal canister of 20 liters.

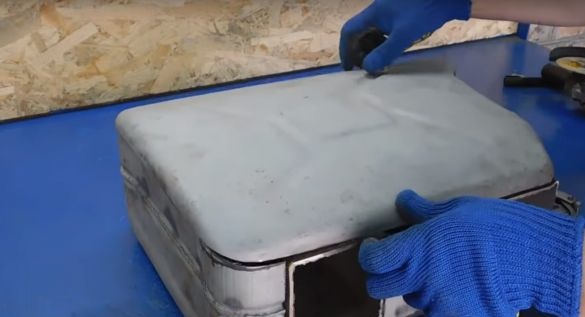

I cleaned it with a sandblast.

During sandblasting, a hole appeared that was not part of the master’s plans. But for our hero there is no such problem that cannot be solved. In the future, this hole will be brewed by the author.

After cleaning, the master carefully cut the canister handle.

After marked on the side walls of the canister.

And cut off one wall of the canister to mark it.

I put a small patch on the unscheduled hole inside as a substrate.

And welded it.

After welding and grinding from the outside, and as you can see in the photo there is not any hole.

Next, the master took a profile pipe 80x80x3 mm.

After marking, I cut two pieces with smooth edges. (The sizes directly depend on the size of the canister.)

And one piece of pipe was cut at an angle.

These are the three blanks of the future stove turned out by the author.

Further, the author cut out some elements of the canister.

After trying on.

And the markup. Future slots and mesh markings on the lower pipe with a diameter of 8mm.

After made holes.

Next, cut the grid around the edges.

And he bent it into the middle of the pipe with a hammer.

In the upper pipe, the author makes a cutout under the pipe with oblique sections.

First fastens all the parts with drops of welding.

And then it boils everything with good solid seams.

Next, place the oven in a canister.

And having put pieces of the profile pipe, the master welded all the mating parts to each other.

Then the author will restore the integrity of the canister by welding into place the previously cut wall.

Further, the author decided to make an additional compartment in the back of the canister. He marked and first cut through only one side, the one on which the loops will be installed.

After welding the loops.

Cut out all over the markup.

To stiffen the door.

He welded a 12 mm metal square to it.

After the master cleaned up all the external seams.

Then he strengthened the handle of the canister.

Welded it back, slightly shifted to the bottom from the original location.

Next, the master will make a box for the rear compartment. Taking a piece of sheet metal, and giving it the desired shape.

The author made several holes for electro rivets.

Putting the box in place.

And fixing it by welding.

On the outside of the door, the master installed a pair of latches.

And he began to manufacture the blower door. To do this, he took two metal plates.

And he shaped them like a photo.

After welded them to the door itself. (As a door, the author used an element cut off earlier from the canister.)

Set it in place.

Like this.

The author secured the firebox door to hinges.

And also to keep it in a closed position.

Our hero made such a retainer from bolts and nuts.

In the end, the author painted a canister with heat-resistant paint, with a maximum working temperature of 400 degrees.

Such an oven turned out by the author.

In the rear compartment, the master put a bag with shavings, a small poker.

And the ignition fluid.

The advantage of such a stove is its low consumption of firewood, and it is also transportable like a regular canister. And of course, the original design.

Before the test, the master took everything out of the back compartment.

And he set about burning the stove.

And then all the most pleasant.

A cauldron of 4 liters, boils in 15 minutes.

And that’s all. Thank you all and see you soon!