In this article, we will look at how the Master made a wooden bed. The bed was durable and beautiful, and for its manufacture he used the following

Tools and materials:

-Board;

-A circular saw;

- Joiner's glue;

- Clamps;

-Knife;

-Bandsaw machine;

- Planing machine;

-Drilling machine;

-File;

- Orgsteklo;

-Pencil;

-Roulette;

-Saw;

- Valuable breeds of a tree for inlay;

-Kalka;

-Carbon paper;

-Planks;

Step One: Material Procurement

To make the bed, the master used mahogany boards. Having purchased boards, the master dried them for several weeks. After drying, the boards processed the boards on a planer, trimming them.

Step Two: Feet

Makes blanks for legs. Cuts the board and glues it together to make four squares with sides about 8 cm.

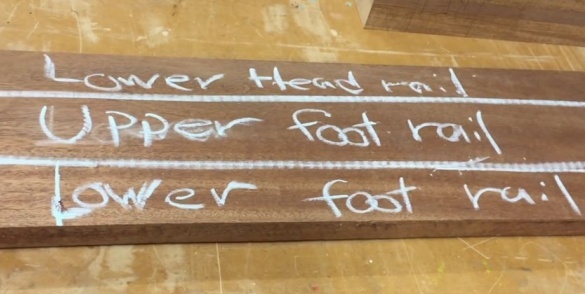

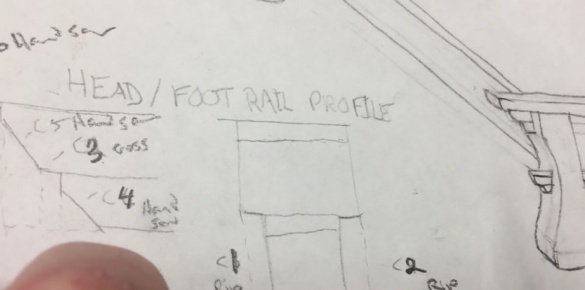

Step Three: T-Board

Makes jumpers for the back and front headboards. Saw boards T-shaped.

Step Four: Connections

Further, the master makes grooves in the legs, and cuts for connection in the T-shaped jumpers.

Step Five: Build

Assembles front and rear headboards. Apply glue for fixation.

Step Six: Inlay

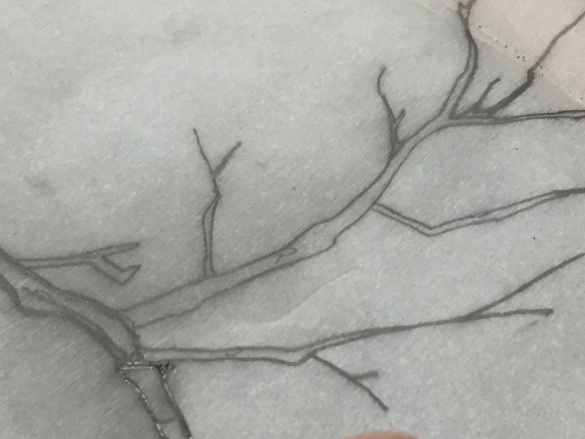

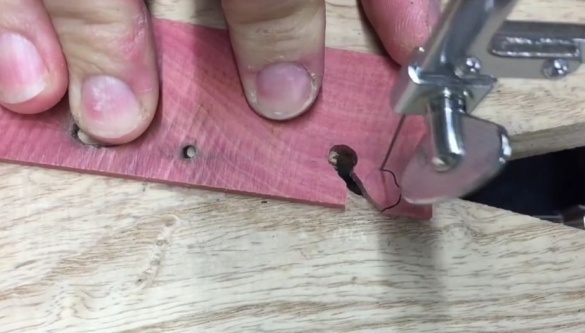

Now the master proceeds to drawing the pattern on the back. First draws a picture on the back.

Then, with the help of tracing paper and carbon paper, he transfers the drawing to the board. Cut each element of the picture from different wood species matching the color. Then he makes recesses according to the drawing, with a knife and a milling cutter, and glues the elements of the picture.

After he finished with the back, the master proceeds to inlay the head of the front back.

Also draws elements.

Cut the branches of a tree and begin to set them.

Then he goes on to sakura flowers.

Coats the surface with varnish.

It is worth noting that the master spent 25 hours on the manufacture of the first drawing, and 63 the second.

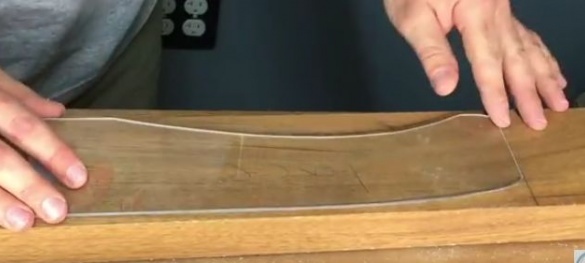

Seventh step: arc

At the head of one of the elements has an arched shape. The master makes this shape of the board with the help of a milling machine. Then cuts the board to size, makes connections. Sets the arc.

Step Eight: Sideboards

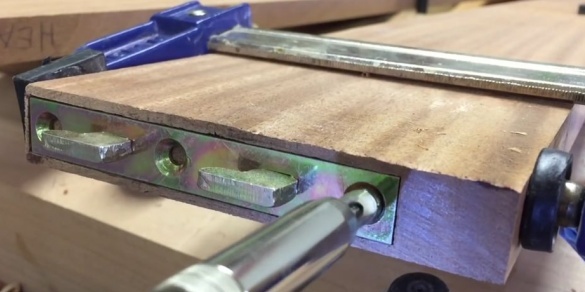

Cuts boards lengthwise.Glues, and then fastens, on the inner surface of the board, the bars for the entire length. From the end screws metal brackets.

Step Nine: Lamellas

After assembling the bed, the master installs the slats. He makes lamels from poplar planks. The ends have a dovetail compound.

It remains to cover the wooden elements of the bed with impregnation.

The bed is ready.