The Peltier effect was discovered back in 1834, and has since been widely used for quite accurate temperature measurements. And in the first half of the twentieth century, it was found that when replacing metals with semiconductors, it is possible to obtain power thermocouples, which are much more powerful than measuring ones.

The Peltier effect is reversible, that is, it allows you to convert both the thermal energy of the temperature difference into electrical energy and the electric energy into the thermal energy of the temperature difference. Especially for nerds: when generating electricity from heat, it is called the Peltier effect, but Seebeck, but you and I are not nerds. Metal thermocouples today measure temperatures, semiconductor - they generate electricity from nuclear decay heat (RTG) and fuel combustion (TGC), cool food in portable refrigerators and processors on motherboards.

Peltier modules for motherboards are widespread, and friends come up with new applications for them. Most often, the result is a mini-power station that runs on a candle. And the author of Instructables under the nickname Luq1308 decided to cool the smartphone with such a module. Although for this purpose just a fan is enough - but also more interesting!

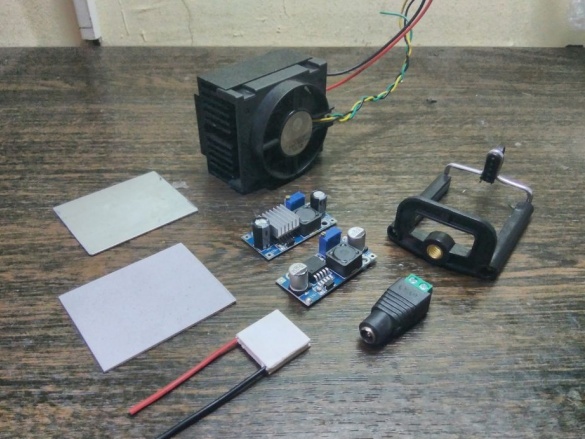

To do this, he prepared a Peltier module of type 12703 for 12V and 3A, a processor fan with a heat sink, a tripod for a smartphone with a holder like a selfie stick, an aluminum sheet measuring 45x50 mm and a thickness of 1 mm, a silicone thermal pad of the same size and thickness, 2 adjustable pulse a converter with an output current of up to 3A, as well as a socket for supplying power. He also stocked with consumables: heat shrink, solder, flux, glue with the properties of thermal paste (domestic AlSil-5 is suitable), wires, cable ties, double-sided adhesive tape and superglue. From the tool he took a soldering iron, wire cutters, an emery cloth, a slotted screwdriver and a file.

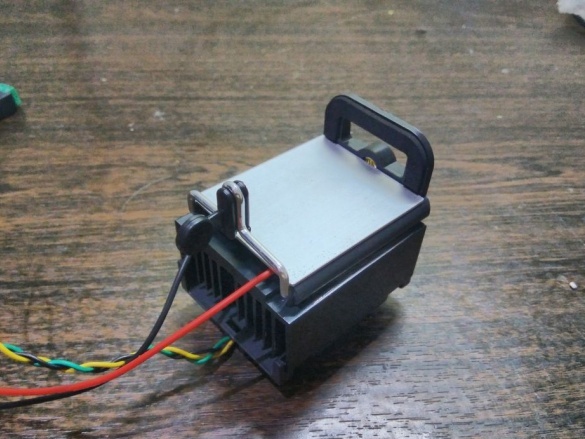

Using adhesive with thermal paste properties, he glued the Peltier module to the smooth surface of the heat sink. Luq1308 tracked to stick the element on the right side, and then, subject to the polarity of the voltage supplied to the module, heat will go towards the heat sink, and the opposite, where the smartphone will be, is cold. He applied glue evenly, and after joining did not relieve pressure until it completely hardened. This is true for all subsequent adhesive joints.

He removed the holder from the tripod Luq1308 and modified it with a file (compare one holder in the photo with the other) to fit the Peltier module.

Having cleaned the contacting surfaces with sandpaper, he glued the heat sink to the holder with superglue so that there was a Peltier module between the walls of the holder.

On top of it with glue with the properties of thermal paste, he glued an aluminum plate.

Taking the first of two pulse converters, he glued it with double-sided duct tape to the heat sink. It is important to take a tape that is thick enough so that the printed conductors on the back of the board do not short-circuit the heat sink. On this converter, he set the output voltage to 5V in advance, and then soldered the wires of the Peltier module to the output in the correct polarity.

Then Luq1308 glued the second converter in the same way, set the output voltage to 13V on it and, also observing the polarity, connected the output to the fan. In fact, it would be possible to get by with a converter with a smaller margin of output current, since the fan consumes no more than 0.2A.

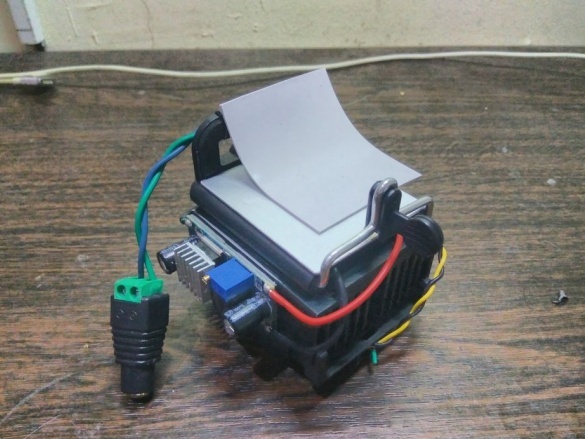

He parallelized the inputs of the converters, and, again not forgetting the polarity, connected to the input jack, which he secured with a cable tie. He took the power supply to the voltage corresponding to the input voltage of the converters, and with a sufficient current margin.

The final touch: press the thermal pad onto the aluminum sheet. Although it can also be glued, Luq1308 wanted it to be removable. The gasket helps heat transfer perfectly.

Having placed the smartphone in the holder and running a demanding task on it, the master proceeded to adjust the transducers to provide the best cooling with minimal noise. It turned out that 8V on the module and 13.5 on the fan correspond to this mode. You cannot turn on the Peltier element when the fan is stopped.

Does it work well homemade? Too! Sometimes, with the indicated voltages, a little condensation even appears on the smartphone. Luq1308 decided to assemble the second such cooler on a less powerful module like TES1-4903, consuming the same current, but from 5V. At the same time, he will use a heat sink of smaller sizes.

P.S. Please note that without a case you will quickly break the homemade product, stop the fan or burn the transducers by a conductive object accidentally caught in them. So do not hesitate in making one.