Compact system "Cyclone - 17".

Good day to all. I bring to your attention the compact Cyclone-17 system for removing dust, sawdust and other bulk materials. This system is designed both for direct connection to a power tool and for cleaning sawdust from the floor. Unlike many similar designs offered, this system is compact with the required power. The system was made to work with wood on the loggia and in the rooms of the apartment. The height of the entire structure is only 1m from the floor, the size of the sole of the machine is 30x40cm. My system was mainly used with hand milling machines, belt and vibration grinding machines, and sawdust cleaning from the floor. 1.5 years of operation have proven its effectiveness and reliability. Convenience and efficiency turned out to be more than I expected. Therefore, I decided to offer this design to everyone.

Especially for the site ""

The system consists of four main parts:

1. Universal vacuum cleaner blower.

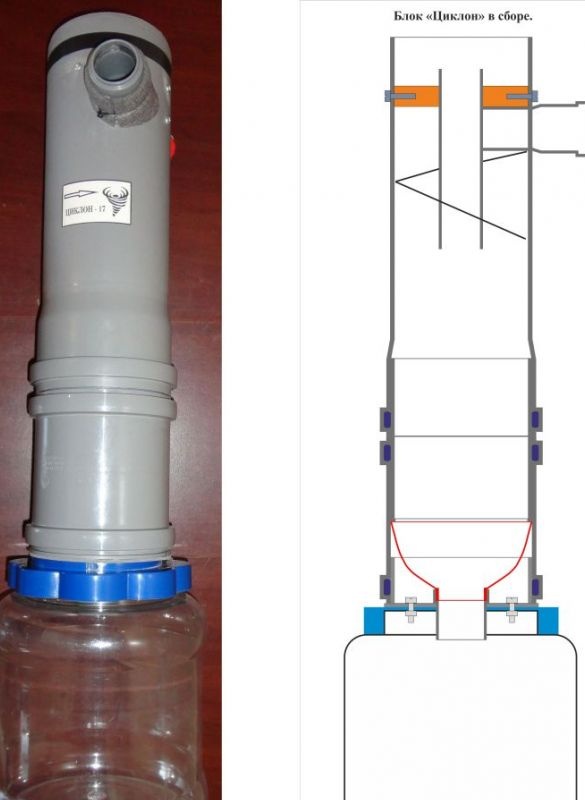

2. Block "Cyclone".

3. The machine on wheels.

4. Block synchronous start.

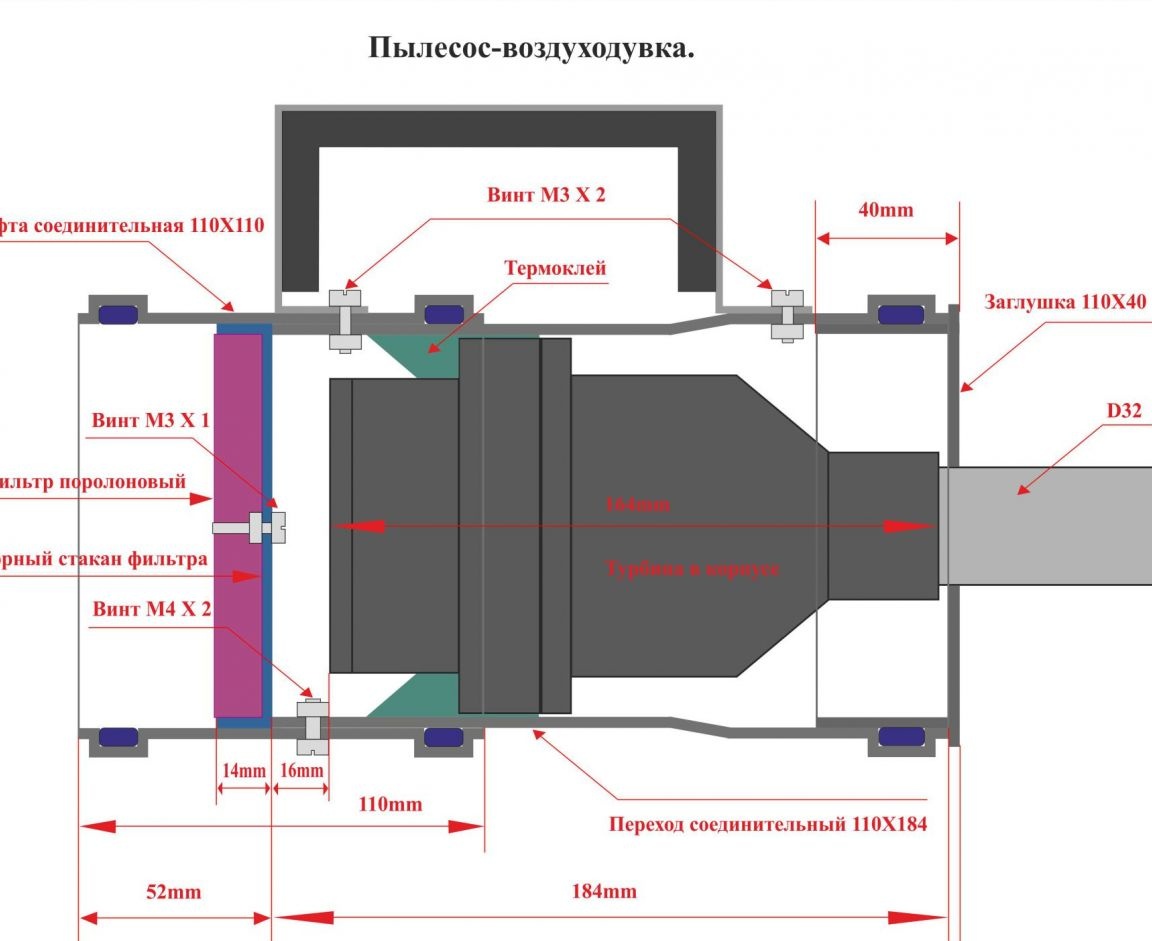

1. Universal vacuum cleaner blower.

2. Block "Cyclone".

3. The machine on wheels.

4. Block synchronous start.

As the main structural material, standard plastic water pipes and a laminated chipboard are used, which is very convenient. A jar from Chupa Chups is used as a container for collecting sawdust, its choice is determined by relative rigidity and transparency (which is very convenient), as well as by a tight threaded connection with a lid.

If there is no possibility or desire to independently assemble a vacuum cleaner-blower, then any household vacuum cleaner of small capacity with a power regulator can be connected to the Cyclone block. Hose adapter design is up to you.

Universal vacuum cleaner blower.

Destination.

The universal vacuum blower can be used as a part of the Cyclone - 17 system. So as an independent mini vacuum cleaner to remove dust in hard-to-reach places (office equipment, audio and television equipment, etc.) and as a blower for blowing dust and sawdust from power tools, office equipment, etc., as well as for pumping inflatable of furniture, pools and. etc.

Separate use.

For the manufacture of the device housing was used:

1. Coupling 110х110 (without an internal side in the middle).

2. A fragment of a fan pipe with a transition of 110x184.

3. The plug is 110x40.

4. Any pen at your discretion.

5. Hose adapters, for individual use.

6. Screws with nuts M3, M4.

Making legs of your choice. At me they are made of fixing plastic corners. They are fastened with M4 screws, from turning they are fixed with hot glue.

Diagram of a universal vacuum cleaner blower.

Filter device.

The filter is cut out in size from foam rubber with a thickness of 14-16 mm, the support cup for the filter is made from a standard plug 110, by cutting and grinding off all the excess (dimensions - see diagram). For better sealing it is wrapped with electrical tape. The filter perfectly filters even the smallest wood dust. Easy to remove and wash.

Power point.

The engine with a turbine (230V 350W) is used from the spray gun for Bosch PFS 65 paint (or Bosch PFS 55, they are the same). The turbine housing is assembled as follows: the front part is from the Bosch PFS 65 turbine housing, the back is from the Bosch PFS 55 turbine housing. The rear part can also be used from Bosch PFS 65, but it will have to be cut off at the edges.

Turbine engine and turbine housing parts.

Complete turbine housing and rear housing from Bosch PFS 55.

Cut off part of the exhaust tube from the front of the case, leaving 2.5-3 cm (see photo). Next, insert a piece of D32mm pipe 90-95mm long into it and fix it with hot-melt adhesive (see diagram).

A hole for a D32mm tube is cut out in the plug housing. Holes are drilled for wire, wire clamp, switch, power regulator.

Switch of any suitable power and size. Any power regulator from a power tool or homemade. I used: a KCD1-1 switch with an indication of inclusion and a power regulator from the MFI Skil 1470 with a triac of 4A. It is conveniently attached to the plug using two metal corners.

A hole for a D32mm tube is cut out in the plug housing. Holes are drilled for wire, wire clamp, switch, power regulator.

Switch of any suitable power and size. Any power regulator from a power tool or homemade. I used: a KCD1-1 switch with an indication of inclusion and a power regulator from the MFI Skil 1470 with a triac of 4A. It is conveniently attached to the plug using two metal corners.

This regulator is necessary when used in a design with a plastic container for sawdust. Since when connecting a tool with small dust-exhausting openings (for example, a vibrating grinding machine), a partial compression of the container is possible (until it is at least half full). Therefore, there is a need for a slight reduction in turbine power. I won’t describe the assembly procedure, it’s convenient for anyone (see diagram, photo).

Block "Cyclone"

The Cyclone block consists of a vortex generator block and a sawdust collection block.

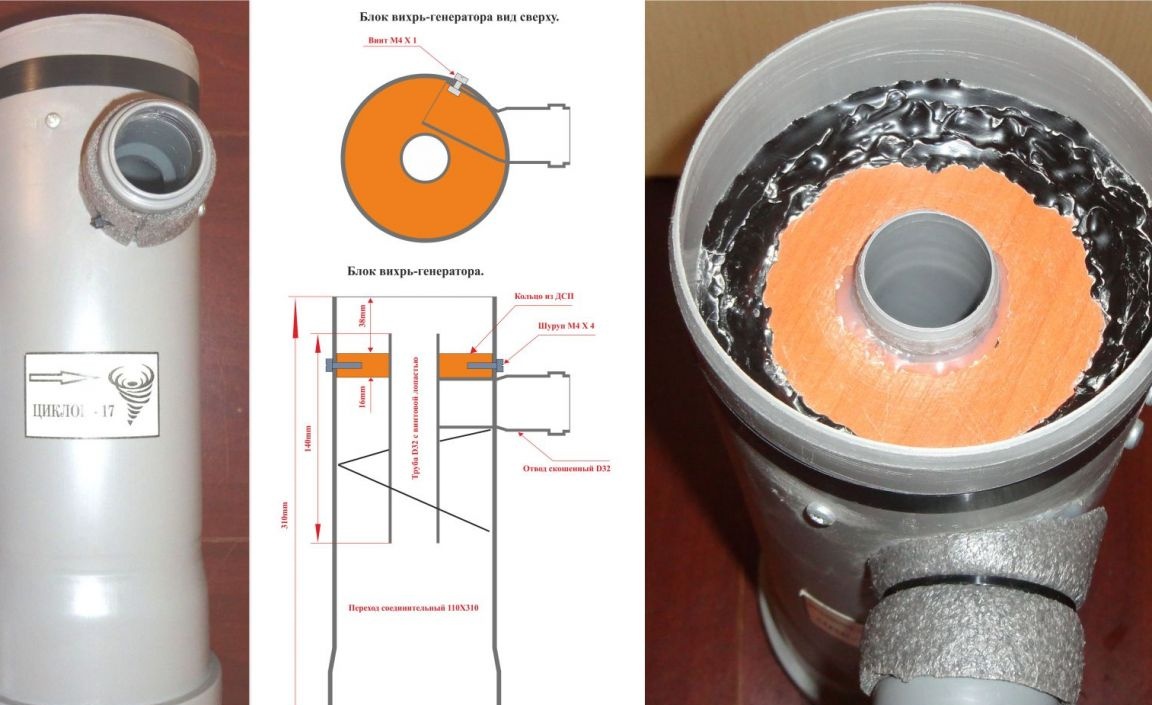

Vortex generator block.

The vortex generator is assembled in a pipe with a transition of 110x310. First, in the pipe 110x310, an outlet D32 is installed, beveled at 45 °. The outlet is fixed in the pipe with a screw with an M4 nut and is fixed and sealed with hot glue (see diagram). The ring is made of laminated chipboard 16 mm thick. The ring in the pipe is fastened with four M4 side screws and hot-melt adhesive (see photo, diagram).

Next, a D32 x 130-140mm tube is installed in the ring with a screw blade fixed to it, fixed with hot-melt adhesive (see photo, diagram). The blade is made of plastic from the box from the DVD disc and mounted on the tube using hot-melt adhesive (see photo).

Next, a D32 x 130-140mm tube is installed in the ring with a screw blade fixed to it, fixed with hot-melt adhesive (see photo, diagram). The blade is made of plastic from the box from the DVD disc and mounted on the tube using hot-melt adhesive (see photo).

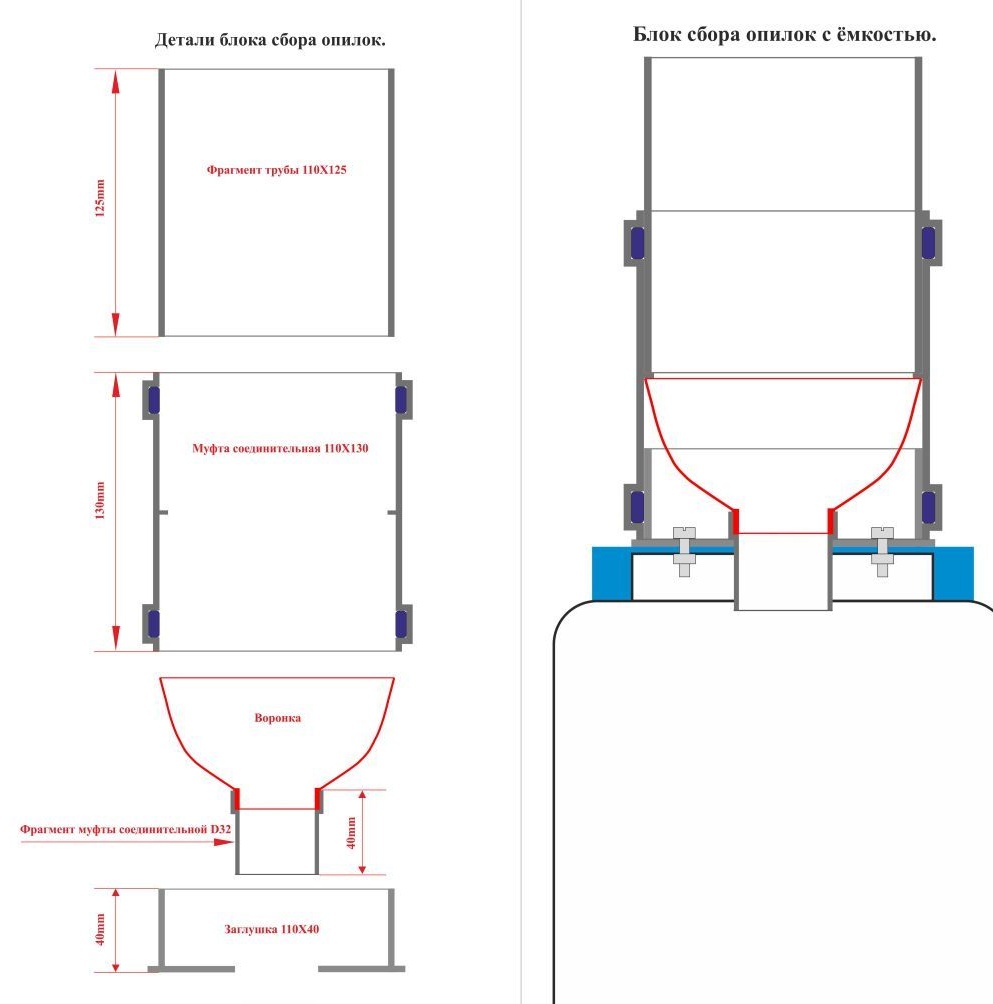

Sawdust collection unit.

Details of the sawdust collection unit.

IMPORTANT!!!

On the rubber sealing rings installed: in the vacuum cleaner-blower (from the filter side) and the vortex-generator block, the inner skirt must be sharpened. For the possibility of separation of these nodes. Otherwise, disconnecting the nodes for cleaning will be very problematic. Leave the rest of the rubber bands as they are. to maintain the device, disconnecting the remaining nodes is not required.

It does not make sense to describe the machine in detail, everything is visible in the photo. The system is attached to the machine using two plastic clamps with latches.

The hose is used from a spray gun for Bosch PFS 65. The ends of the hose are fixed in the tubes using hot melt adhesive. [/ Justify]

Tips for cleaning sawdust from the floor.

At the end of the flat nozzle, I recommend making side holes (see photo). They prevent unexpected plugging, which can lead to compression (deformation) of the plastic container. They do not affect the quality of cleaning. A standard telescopic brush from a household vacuum cleaner is also used.

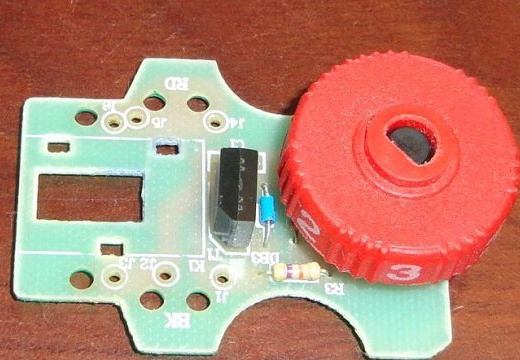

Synchronous start block.

I took the synchronous start-up circuit on the Internet. It is repeatedly described in detail on different sites. Many thanks to its author. The only thing that had to be replaced by the indicated parts on the diagram on the Internet with the analogs (diodes, triac) that were at hand. PCB size 50x70mm. The board fits comfortably in a 78x78mm wiring box.

The unit is attached to the machine with screw furniture ties. Therefore, it is conveniently installed and removed.

If you need additional information, write to the post office, I will try to be sure to answer. Feedback, suggestions and comments are very welcome.

The unit is attached to the machine with screw furniture ties. Therefore, it is conveniently installed and removed.

If you need additional information, write to the post office, I will try to be sure to answer. Feedback, suggestions and comments are very welcome.