Hello everyone, in this instruction we will look at how do it yourself make a simple and powerful hydraulic splitter. As the main working unit, the author used, which is manually actuated, by human power. Due to the design features, the splitter is quite slow, but the usefulness of such homemade still there. With the help of such a wood splitter, you can easily split even the most problematic lumps, which have many knots.

Also, if you wish, you can upgrade the design by installing an electric motor on it, which will drive the hydraulic jack. As a result, the system will be able to work by pressing a button. So, let us consider in more detail how such a splitter can be made.

Materials and tools used by the author:

Material List:

- ;

- thick sheet steel;

- I-beam or channel (for the frame);

- two springs;

- bolts with nuts;

- paint and primer.

Tool List:

- grinder;

- welding machine;

- drill;

- roulette.

The process of making wood splitter:

Step one. Assemble the frame

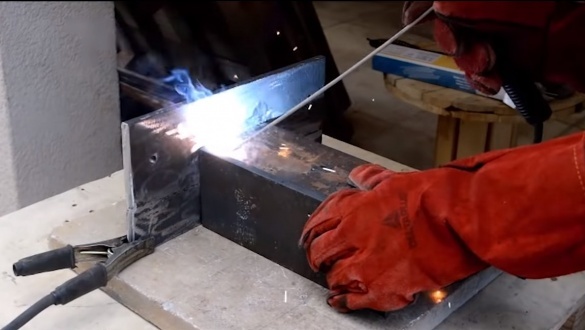

The frame of the wood splitter is its most important organ, huge loads are here. To make the frame, we need a channel or an I-beam. To begin with, we make all the necessary measurements and cut the workpieces. We will need more pieces of sheet steel to make mounting plates and strengthen the entire structure.

The greatest attention should be paid to the racks, here the maximum load will fall. For their manufacture, the author scald the I-beam with sheet steel, as a result, rectangular details were obtained. When all the components are ready, the whole structure will need to be properly welded. We clean the metal well so that the product can then be painted.

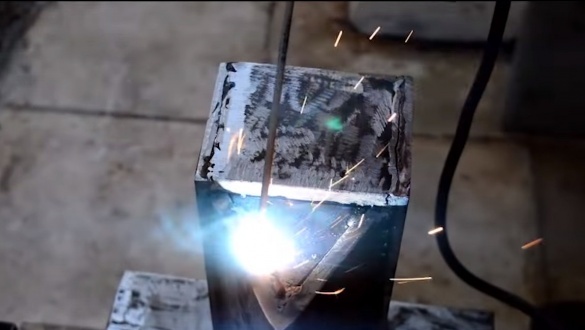

Step Two We make a wedge

We need a wedge in order to split chocks. This part of the structure must also be strong. The author decided to weld a wedge of thick sheet steel. We cut two pieces and weld them in the form of a triangle on the upper rack. Wedge can be sharpened to improve homemade productivity.

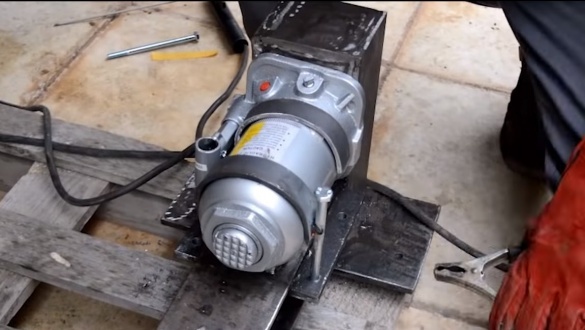

Step Three Jack installation

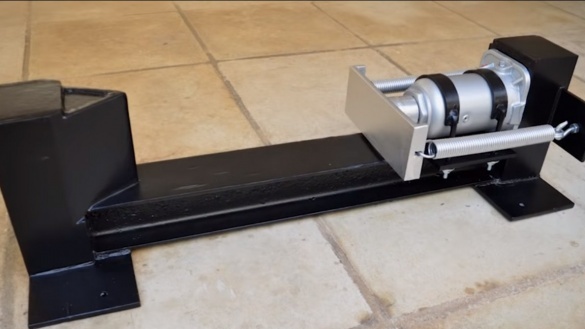

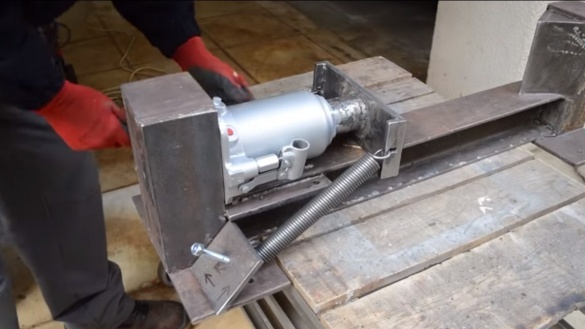

The jack will abut against the bottom rack. To begin with, you need to slightly raise it above the frame, for this the author welds several steel plates to it. It is also important for us to securely fasten the jack so that it does not pop out in the process of splitting firewood. For such purposes, we will need four bolts with nuts and sheet steel. From these components, the author made two clamps, with which the jack is firmly attracted to the frame with nuts.

Step Four Making a return device

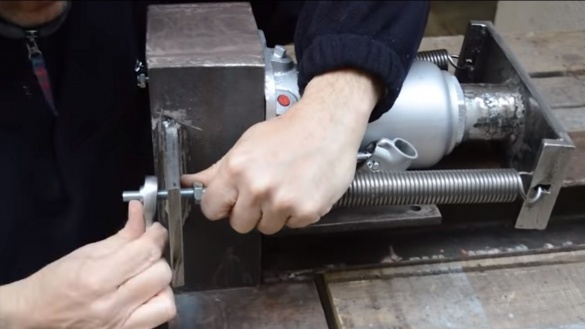

After the chock is split, we need to return the jack to its original position. For such purposes, it will need to be equipped with springs. Among other things, we need to make a persistent platform on which we will install chock. The supporting platform is welded from sheet steel, ears are welded to it for attaching the springs. And so that the support platform is securely fixed on the jack, we weld a piece of a round pipe to it in the center and install the nose of the jack in it.

On the frame we also need to weld two ears for attaching the springs. We install hooks in the holes and install springs. After tensioning the springs, the author cuts off the excess ends of the threaded rods.

After that, the design can be tested in practice.

Step Five Painting

So that the metal does not rust, and the wood splitter looks beautiful, we need to paint it. For high-quality painting, we cover the metal with a layer of soil, and then paint, the author chose a black paint. When the paint dries, the splitter can be collected.

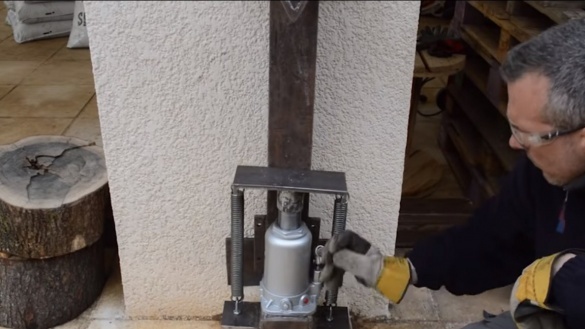

Step Six Installation and testing

The author sets the wood splitter near the wall, and so that he does not fall, we fasten the device to the wall. The machine takes up little space and looks beautiful. Now we proceed to split the firewood. The view shows how easily the wood splitter copes with chocks with knots. It would be long and difficult to chop such chocks manually.

That's all, the project is over, I hope you liked it, and you found useful information for yourself. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade products and ideas with us!