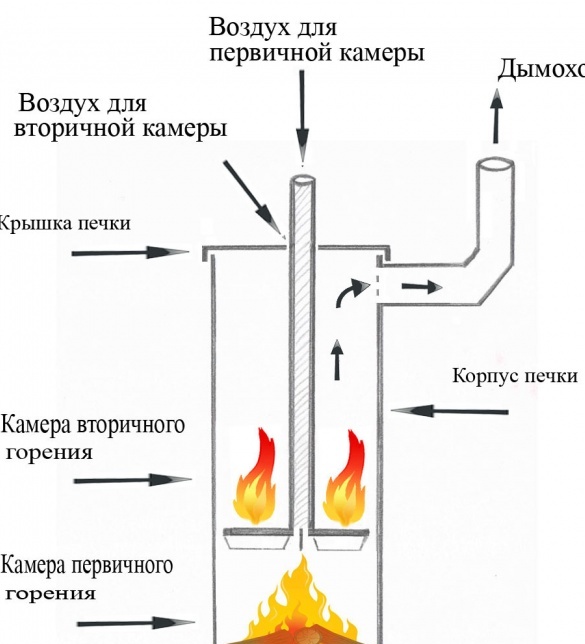

I propose to consider such an interesting design of the furnace, which was called "Bubafonya". Such a furnace is classified as a long-burning furnace, and it can be heated with almost anything, from ordinary firewood to sawdust, grass, bark, and so on. The peculiarity of the furnace is that combustion in it occurs from top to bottom, and not vice versa, as in classical furnaces. The air supply is also carried out from above, and the air is heated up until it reaches the burning point of the wood.

Also, the design is interesting in that the firewood on top is pressed by a plate with an impeller. Thanks to the plate, a combustion chamber is obtained, the plate presses on the wood and the combustion chamber decreases depending on the degree of combustion of these firewood. And the impeller is needed so that the incoming air forms a vortex at the combustion point. Of course, the design is rather sophisticated and it is hard to fully understand the principle of operation of such a furnace, but, according to its owners, it works quite interestingly and efficiently. Consider how to make such a furnace out of a gas cylinder!

Materials and tools used by the author:

Material List:

-Two gas cylinders;

- Inlet pipe for air supply;

- outgoing chimney;

- thick sheet steel.

Tool List:

- welding machine;

- grinder;

- a drill with good drills for metal;

- roulette;

- marker;

- clamps.

The manufacturing process of the Bubafony furnace:

Step one. Gas bottle preparation

Working with a gas cylinder implies a high danger, if you just start cutting the cylinder, it will most likely explode. There are tons of ways to clean a balloon. The easiest way is to fill it under the neck with water and start cutting directly with water. But at the same time you need to be careful and try not to wet the grinder, since you can earn an electric shock.

Some other craftsmen thoroughly wash the bottle with water and detergents. Water must be used hot so that flammable substances evaporate.But such a procedure needs to be repeated several times.

In any case, first remove the tap and drain the contents from the cylinder. What flows out is a combustible substance, the properties of gasoline are similar to gasoline. Therefore, avoid open flames.

Step Two Cutting and welding

When the cylinders are prepared for cutting, we arm ourselves with a grinder and get to work. We cut off the neck of both cylinders. One cylinder will be the main one, and from the second we will cut a piece to extend the furnace. When everything is ready, weld all the parts together well. As a result, the design obtained by the author has a height of about one meter.

Step Three Cover making

To make the cap, we need the top of one of the cylinders. So that the cap is well fixed on the cylinder, we need to make a protrusion in its inner part. To do this, cut a piece from the container, and then cut the resulting rim and narrow it so that it goes inside the container. That's all, now we do this weld to the inside of the lid. As a result, we get an excellent cover, which is tightly and securely installed on the furnace.

Step Four We mount a chimney

In the upper part of the furnace you need to make a hole for the chimney. The author makes such holes with a drill. We drill a series of holes, and then knock out the part with a hammer. The hole can then be modified using a file. That's all, it remains to weld the chimney.

The author needed to weld a knee to bring the chimney out onto the street. To cut pipes at the right angle, it is recommended that you first make paper patterns.

Step Five Production of air intake

The air intake is a piece of pipe with a plate at the end, the pipe passes through the furnace to the furnace. Select the desired pipe and cut a piece of suitable length. The length of the pipe should be slightly longer than the length of the furnace so that it does not completely fall into the furnace when all the fuel has burned.

Next, we make a separation plate, it should be made of thick sheet steel, since there will be a high combustion temperature inside the furnace. We need to cut a circle of such a diameter so that it enters the cylinder with some clearance. The magnitude of this gap, unfortunately, is unknown. We cut out the circle by drilling holes; here it would be nice to have a drilling machine.

In the center of the round log we make a hole for the inlet pipe and weld it. For even distribution of air over the combustion chamber, an impeller is mounted on the plate. For its manufacture, you can use a corner or other similar material.

Step Six We finish the furnace cover

The furnace is almost ready, it remains to make a hole in the lid under the intake pipe. The gap here should be small, but at the same time, the pipe should easily pass through the cover. You also need to weld two handles of thick wire to the lid.

That's all, after that the stove is ready. Firewood is loaded from above, burned similarly also from above. The furnace closes and a slow and efficient combustion process begins.

Of course, in the lower part of the furnace you still need to make a door so that it is more convenient to set fire to the furnace, monitor the combustion process, and also dig out the ash. But the door should be airtight, as the air supply is planned from above.

That's all, the project is over, leave your opinions on this design, and also write reviews if you have such an oven. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade with us!