I welcome fans to craft, I propose to consider a motorized earth drill, which can be made on the basis of a chainsaw. Whether it makes sense in this project or not, it is up to you to decide whether you can get the necessary materials and how much they will cost you. As the “heart” of the device, a gearbox with a ratio of 1X100 is used, this gearbox is called Bonfiglioli VF49. You can buy it or use a similar one, anyway homemade you should be much cheaper than buying a new earth drill.

It’s not difficult to assemble the device, the chainsaw does not change in any way, it’s just like a nozzle for a chainsaw.

Now you will not need to dig holes in the shovel to dig in the posts, this can be done in minutes using this homemade drill. If you are interested in the project, we will consider in more detail how to assemble a homemade product!

Materials and tools used by the author:

Material List:

- manual earth drill;

- chainsaw;

- gearbox Bonfiglioli VF49;

- Sheet steel;

- roundabout.

Tool List:

- lathe;

- drill;

- taps for threading;

- grinder;

- vise;

- pendulum saw;

- plasma cutter;

- belt sander;

- screwdriver, wrenches.

Homemade manufacturing process:

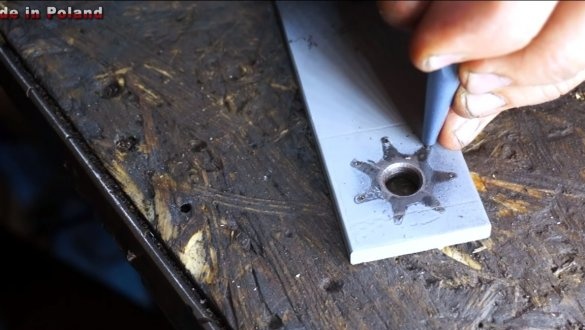

Step one. Adapter manufacturing

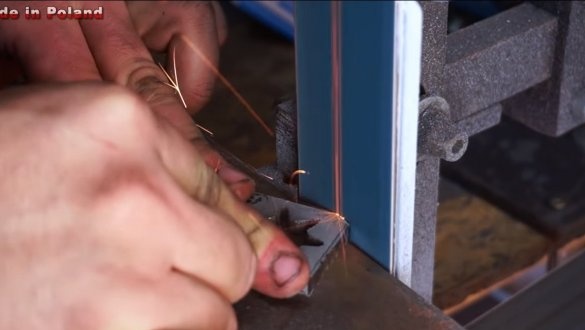

To begin with, we need to make an adapter, with it we will connect the drill gear to the chainsaw sprocket. To do this, the author removes the star from the saw and outlines it with a marker on thick sheet steel. Next, the marked area needs to be cut out, for this first we drill a hole in the center. Well, then we cut out the rest using a jigsaw, and then files. As a result, the part should be easily worn on the chainsaw sprocket. We give it a round shape, cut off the excess, and then grind it on a belt grinder.

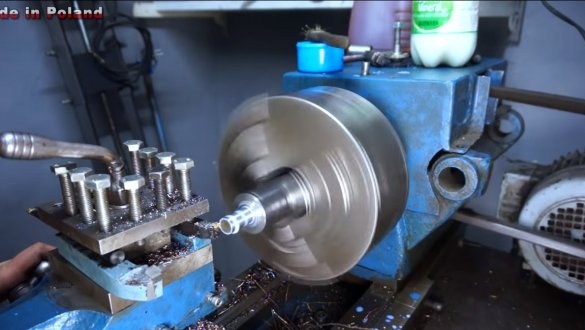

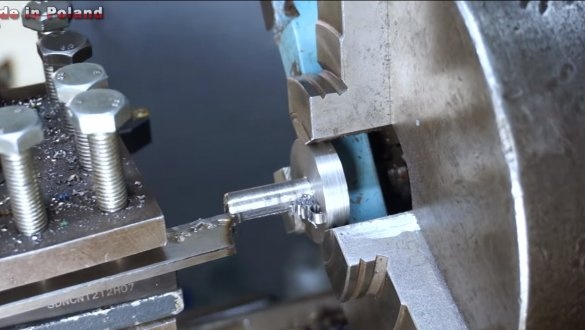

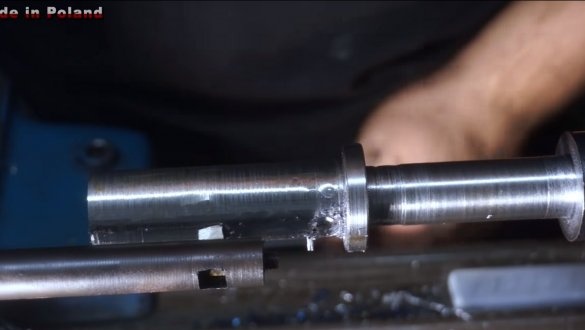

Next, we need to make an axis, with which we will connect to the gearbox. There should be a keyway on the axis, as well as a place for attaching the previously manufactured parts for the sprocket. To make this part you will need a lathe. We grind the necessary part, drill holes, cut the thread and screw the part with screws to attach it to the sprocket.

Step Two Mount to the grinder

Next, we need to figure out how to mount the gear to the grinder and the mount must be reliable. Its author carves from thick sheet steel.The mount is screwed to the gearbox, and the whole thing is attached to the chainsaw using standard nuts for attaching the tire.

Step Three Pens

The design is quite weighty, and the loads during drilling are not weak. The handle will be fixed to the gearbox, first cut a round plate and drill holes. This plate is screwed in the place of the gearbox, where the shaft comes out with reduced speed. Next, a plate is welded to the handle, which the author bent so that it goes to the handle of the chainsaw. As a result, when you hold the saw, you also hold the gearbox. We also weld the handle for the second hand, its author makes of a piece of pipe, welded to the plate on the gearbox.

Step Four Drill Installation

We need to make an adapter for the reduction output of the gearbox, its author also grinds it on a lathe. Well, then we install the part on the gearbox and put on an earth drill.

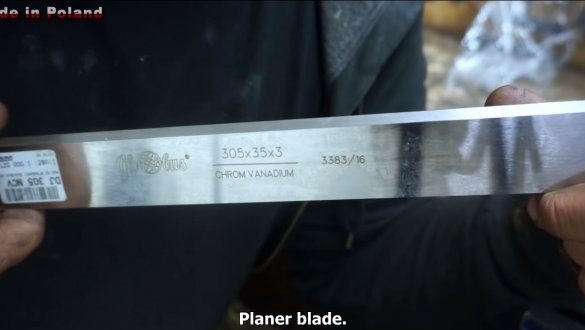

In addition, the author installed knives made of chrome-vanadium steel on the drill so that it pierces the roots well and, on the whole, the drill drills well.

That's all, the homemade product is ready. We start a saw and try to drill. The author of the video shows that the drill drills the earth without much effort, now to build a fence will not be a big problem. That's all, the project is over, good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade products with us.