This tool will allow you to install sheets of drywall overlap, as a result of which the joint is neat, putty is not required, and the connection is more reliable. Everything is done on the basis of a grinder, the nozzle is very simple to manufacture. The main material for the manufacture is plywood. When the device is operating, almost no dust is generated, since a vacuum cleaner is connected to the nozzle. If you need one homemade and I wonder how it works, I propose to get acquainted with the project in more detail.

Materials and tools used by the author:

Material List:

- plywood;

- self-tapping screws;

- a rubber part for connecting a vacuum cleaner hose;

- screws and nuts.

Tool List:

- circular saw or hacksaw;

- drill;

- screwdriver;

- a screwdriver.

Homemade manufacturing process:

Step one. Fasteners

First, we make a part with which the nozzle will be attached to the grinder. This part is a rectangle with a hole cut out. The part is screwed on with screws that secure the working axis of the grinder to the gearbox. Only regular screws are twisted and installed by the author.

Step Two Reference area

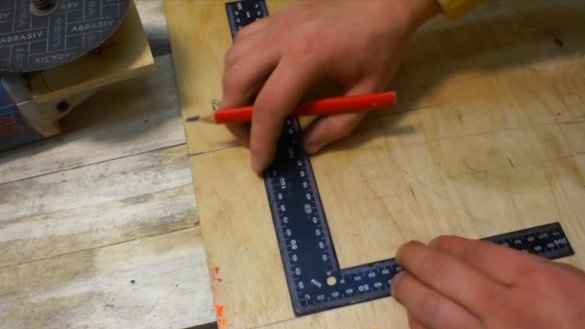

Next, we need to cut out of plywood and install a support platform. With it, we will rely on a sheet of drywall when cutting. This sheet must be screwed through a spacer of a suitable hollow from OSB, plywood and so on. The bottom line is that the cutting disc is at the right distance from the supporting platform. We fasten everything with screws and nuts.

Step Three Thrust piece and hood

Opposite the disk, a thrust piece is installed, it is needed so that the disk comes into the material at a clearly defined depth. We assemble it from pieces of plywood on self-tapping screws and fasten it to the device.

In addition, a lid with a rubber ring is installed here, into which you can insert a hose from a vacuum cleaner to suck in dust.

Step Four A pen

Attach the handle from the grinder to the nozzle so that it is comfortable to hold. To do this, the author built a special nut from plywood and screwed it to a homemade product.

Step Five Test

We turn to the tests, make a cut in a sheet of drywall, as a result, we will peel off the paper and get a certain deepening. The depth of this recess will depend on the thickness of the disc used.

Next, you need to glue the paper back, we use PVA glue. And so that the glue dries quickly, and the paper is firmly adhered, we draw on the paper with an iron

That's all, the homemade product is ready, everything works fine. Good luck and creative inspiration!