All residents of private homes with household plots will agree that the furniture on the terrace or in the garden — chairs, benches, stools, tables — is subject to rapid wear without proper care. High humidity, temperature changes and other factors contribute to the rapid decomposition and aging of wood. In this regard, all kinds of impregnations, varnishes, paints that promote the conservation of wood have been developed. It has long been noticed that the part of furniture that is in direct contact with soil or artificial surface - asphalt, tile, cobblestone, etc., is most susceptible to decomposition. Legs are the most vulnerable part of furniture. How can they be protected?

Mark offers one non-trivial way to protect your legs from epoxy. It creates a kind of pillows, they are good in that they not only prevent the penetration of moisture from the ground, but also fasten the wood fibers together, preventing them from dispersing. And this is a very significant point, because people sin by involuntarily stretching chairs and other furniture on tiles, cement screed and, thus, severely damage the legs.

Epoxy will prevent the breakdown of wood. Such pads are made very simple.

Materials

- Two-component epoxy resin

- Teak oil

- Masking tape.

Instruments, used by the author.

- Orbital sander

- Sandpaper.

Manufacturing process.

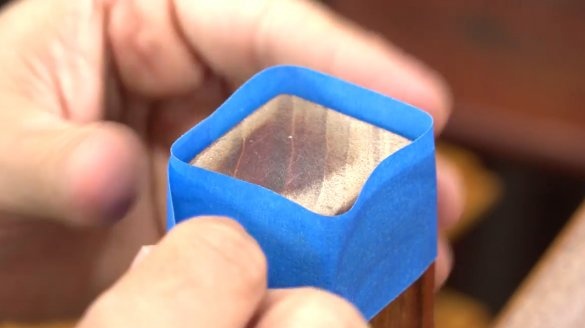

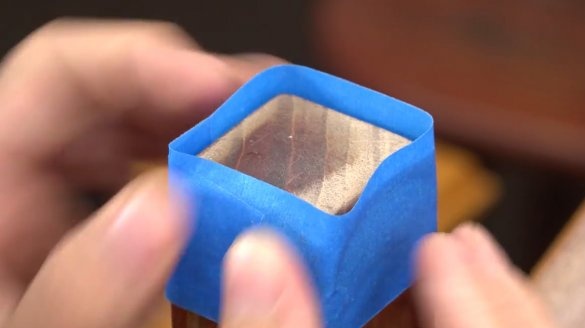

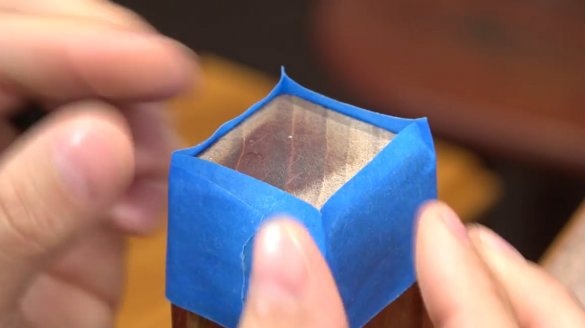

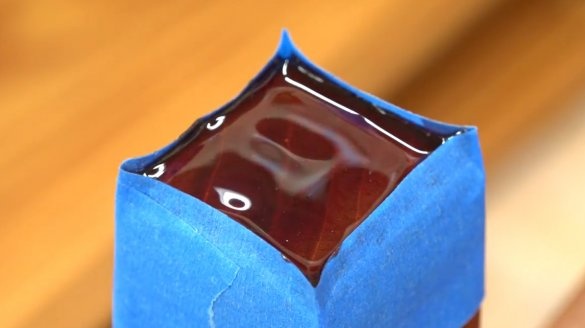

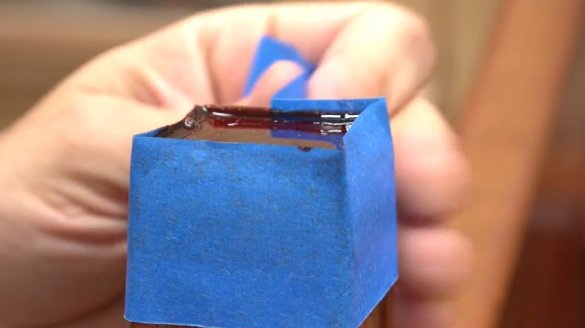

An ordinary masking tape is taken and the leg of a chair or chair is wrapped around it - this creates a mold for epoxy.

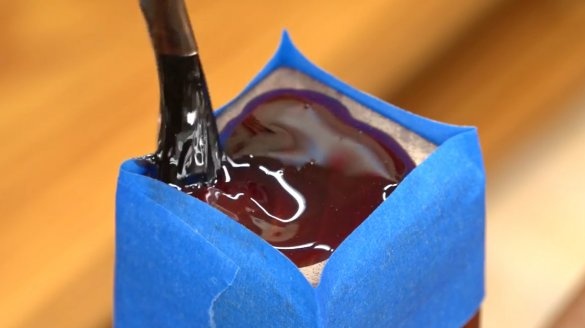

This brand of epoxy is called the West System. This is a high-quality resin, it has a very liquid consistency. Such a resin can perfectly fill all the voids. Just pour the resin into the resulting impromptu shape.

Since the hardener was not the first freshness, he gave the resin a dark bard shade akin to mahogany.Thus, the epoxy “sole” remarkably “merged” in color with the wood.

If the wood is fresh, it is likely to absorb some epoxy. Therefore, after a few minutes, the procedure will have to be repeated.

Ultimately, after proper treatment, a good half will remain from the original resin layer.

Epoxy is known to be a self-leveling material. Due to its surface tension, it spreads and creates a perfectly smooth surface. The polymerization of this particular type of epoxy resin occurs within 24 hours. Already in the evening, Mark removes tape.

To smooth out irregularities, he polishes the material with a grinder, then with fine sand paper. It is very important - the touch should be very light.

And now the legs of the chair are ready! The author uses only a small amount of teak oil to hide clouding and minor scratches.

Thus, a little epoxy resin will provide furniture with reliable protection against external environmental influences.

The great thing about this method is that it can be used on furniture of any age, both on a brand new, still untouched by time, and on old, shabby pieces. And it really will prolong their life!

Good luck to everyone and good mood!