Hello everyone, I offer you to consider instructions on how to make a high-quality and beautiful knife from Damascus steel. With this knife you will surely surprise your hunting companions, and such a knife will be very useful in tourism. Of course, getting Damascus steel involves a forging process, so for the manufacture you will need a forge furnace and an anvil. In general, the author also used other rather not widespread equipment, such as tape cutting machines, belt grinder and more. But if this does not scare you, and you want to try to make a similar knife, I suggest studying the project in more detail!

Materials and tools used by the author:

Material List:

- several grades of carbon steel;

- wood with a beautiful texture (for a pen);

- steel rod for pins;

- steel for guard;

- epoxy adhesive.

Tool List:

- belt sander;

- tape cutting machine;

- drilling machine;

- blacksmithing supplies;

- grinder;

- acid for etching;

- grinding stones;

- oil for wood impregnation.

The process of making a knife:

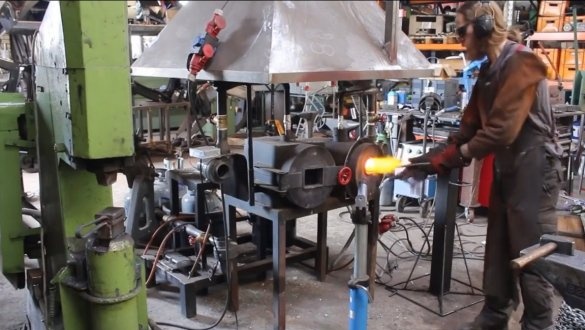

Step one. Forging

We begin the process of making a knife, of course, with forging. To get Damascus steel, you need to mix well several grades of steel. To do this, you need to wrinkle, twist, the longer, the better. The more layers Damascus steel has, the better it is considered. Of course, steel should be carbon, only in this case it can be hardened, and the blade will be very strong.

By forging, the author also forms the main profile of the knife.

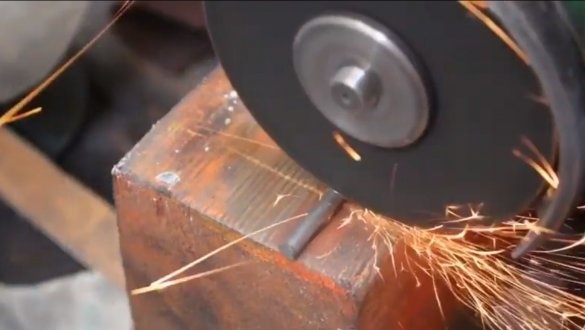

Step Two Grinding and beveling

After forging, we proceed to grinding, it will allow us to get the final profile of the blade. Here comes the belt sander to the rescue. We process the knife along the contour and grind the plane. The author also forms the slopes on the blade, all this is done by eye. If there is not enough experience, it is better to mark everything out initially. Draw a line along the future blade in the center to remove the same amount of metal from both sides. While the blade does not need to be sharpened, hardening is ahead, steel with a thickness of less than 2 mm during hardening can overheat and become fragile.

After polishing, the author conducted a test etching in acid to see what the pattern on the blade would be like.

Step Three Holes

In the handle we drill holes for pins, it is desirable to release the steel first.To make the handle easier, more holes can be drilled, then it will be convenient to chop with a knife like an hatchet.

Step Four Quenching and pickling

Now the blade can be hardened, but first the author decided to put his own brand on it. Before hardening, the blade is recommended to be normalized so that it does not deform and does not crack during hardening. Heat the metal red and let cool in air.

Now you can harden and cool steel better in warm oil, so there is less chance that cracks or deformations will appear. Steel should be heated to a temperature at which it ceases to be attracted by a magnet. To know a more accurate temperature, you need to know the grade of steel, however, we have Damascus steel, here you need to select the temperature regime yourself.

After hardening, steel is usually released, but the author missed this point. If the leave is not made, the blade may be fragile.

After hardening, we clear the blade of scale and perform light grinding. After polishing, we etch the blade in acid to get a damask pattern. Each steel grade in acid darkens differently, as a result we see this marvelous pattern. But here it is important not to overexpose the blade, otherwise acid can leave shells. After etching, wash the blade well under running water and polish it as desired.

Step Five Garda

We make a guard, the author has steel. Here we need thick sheet steel, you can weld several pieces together to get the desired thickness. We cut the workpiece with a grinder and make a cut to fix the guard on the handle. We will fasten it with a rivet. The author sets the rivet by forging, that is, it must be heated with a gas burner, and then riveted. As a result, the whole structure is very strong. We give the final look to the guard by grinding on a belt grinder.

Step Six Pen making

For the pads on the handle, choose beautiful wood, it will depend on how your knife looks. The author dismissed the board on a circular saw, as a result, two pieces of the required thickness were obtained. Prepare also the pins, they are steel by the author.

Pads can be installed, usually they are installed both at once, and only then handle is polished. But the author sets each pad separately and in the process drills holes for the pins. As glue we use epoxy.

We form the desired shape of the handle, the bulk of the material is removed using the petal nozzle. Well, then a belt sander comes to the rescue. We bring the pen to a perfectly smooth state by hand using sandpaper.

Seventh step. Impregnation

The handle is necessarily saturated with oil, it will protect the tree from moisture, which it loves to absorb. Here, ordinary flaxseed oil or special oil for wood impregnation is suitable. Under oil, the wood will look amazing.

Step Eight. Sharpening

Sharpen the knife, here we need grinding stones. At the end, we sharpen with the smallest abrasive, as a result, the blade can be brought to a razor condition. In this state, the blade will remain for a long time if high-quality steel is selected. The author’s knife easily cuts paper. Do not forget to make a sheath for such a sharp knife!

That's all, the project is over, the knife turned out amazing. I hope you enjoyed the project, good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas with us and homemade!