Good afternoon, aircraft modellers.

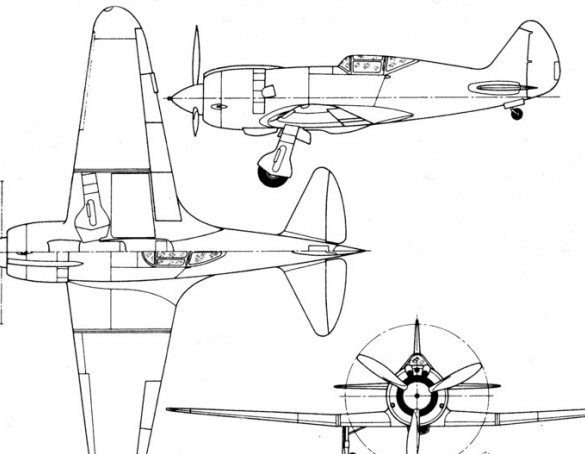

Today I decided to talk about a very interesting aircraft model of the famous high-speed, high-altitude fighter that flew during the Second World War - this is the MiG-3.

Which of us was not enthusiastic about his flights, watching films about the war. The author did not seek to make a copy of the aircraft, but he managed to convey the main recognizable features of this aircraft. Model made here according to these drawings.

TTX.

Flight weight - 850 gr.

Length - 900 mm.

Span - 1400 mm.

Engine - ST3508 750 kv

Battery - 3S 2200 mA

Screw - 10 x 6 thrust 750 gr.

Screw - 11 x 7 thrust 900 gr.

Materials

Heater "Penopleks" - 20 mm.

Ceiling tile (ceiling) - 5 mm.

Glue - epoxy.

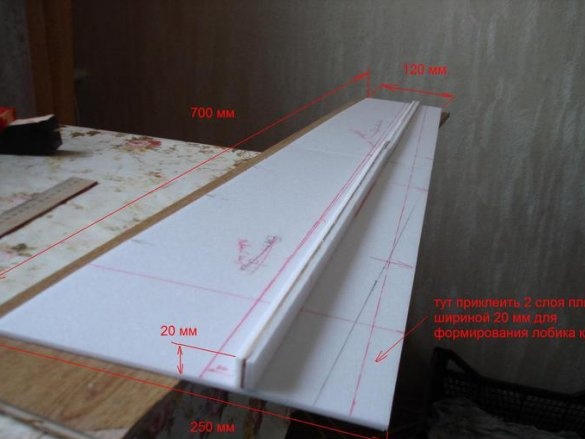

All the main dimensions and dimensions, the author put in the photographs.

The author first made blanks for the sides of the fuselage from the insulation.

For the future hood and gargroth, a piece of insulation is glued in the nose of the fuselage.

The fuselage is smoothed out with fine sandpaper.

The lower surface of the wing is made from the ceiling.

Glued plywood -4mm. on which the motor will be mounted.

The wing attachment points are reinforced with plywood.

The battery and regulator are installed.

The wing spars are made of wooden rulers reinforced with strips of ceiling.

A strip of ceilings is glued to the front edge of the wing blank, this will be the forehead of the wing.

Ribs are cut from a heater.

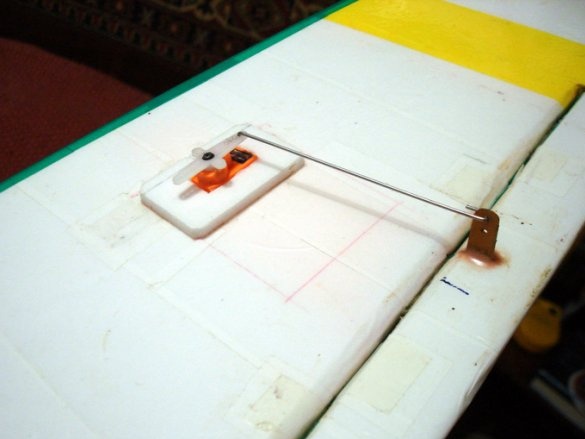

Servos are installed, wires are laid, and then the outer skin of the wing is mounted.

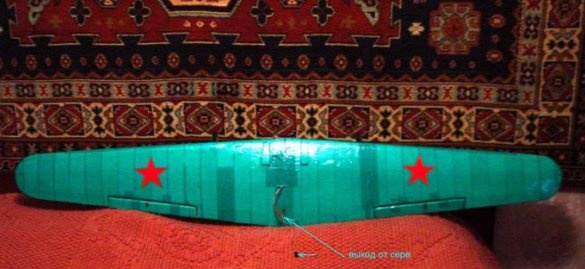

It looks like a wing.

The wing is reinforced by glued insulation.

The thickness of the wing at the root rib is 30 mm.

Servos installed. For durability, ribs are made wider at the mounting points of servos.

When gluing two wing halves, V kgol is made - 2-3 degrees.

This is how the finished wing looks.

The wing is inserted into the prepared groove and fixed.

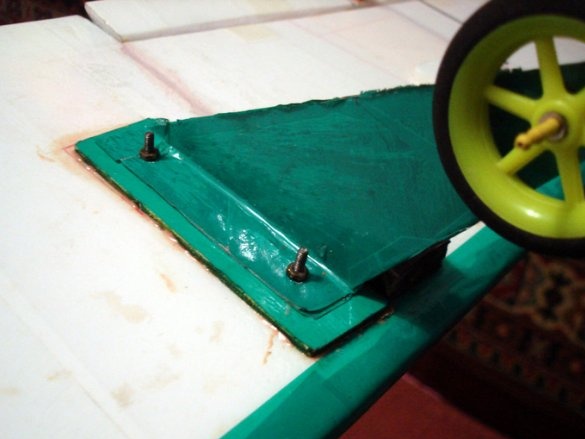

On the wing glued pieces of the ceiling, which prevent the displacement of the wing. The wing is fixed with a self-tapping screw. The screw-in point is reinforced with a piece of PCB 30 x 30 mm.

PH is static.

Chassis racks are made of 1 mm duralumin. thick, mounted on pieces of wooden rulers glued from the bottom of the fuselage.

This is how the fuselage assembly looks.

And this is an assembled model.

The author built a hood from a plastic bottle.

The author was pleased with the flight qualities of the model he had assembled.

A small video of the flight of the model.

All the best, see you soon.