Hello, friends.

The author of this homemade recently made repairs on the chassis of his car; as a result of the repair, old parts remained. Being a guy not stupid and even with properly grown hands, the author decided to make a bracket for an angle grinder, she is also a Bulgarian. The manufacturing process is very simple, and it will not require specific tools. And whoever doesn’t have an old ball valve in the coffers, it can easily be found at any car service station, I think there is enough such good with our roads.

Tools and materials.

Manufacturing process.

Actually all you need to do is make a transition under the grinder and fix the resulting bracket in a convenient place.

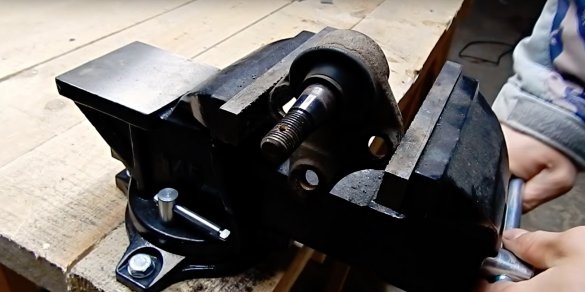

The author clamps the ball in a vice, puts a 17mm nut on the support rod, and since the threads on the ball and nut do not match, the author simply welds the nut.

Now you need to weld a 13mm connector nut onto an already welded nut.

The author drills holes on the desktop and fastens the bracket with screws.

To connect with the bracket, the grinder will need a stud or a long bolt, the cap of which can be cut off, which the author actually does. Two nuts are screwed onto the stud and two grovers are put on the edges of the stud.

The author winds the pin on the bracket, puts the grinder on the pin, screwing the pin into the hole where the handle used to be attached.

Fixes everything with two nuts. One nut is clamped to the bracket, the other will fix the grinder.

Well, that’s all, I’ve said that this is a simple home-made.

It's time to test the product. The master grinds the hairpin and at the same time the grinding machine does not deviate, does not vibrate and is well fixed. But if necessary, the author can easily change the angle of its inclination.

Thanks who read to the end, good ideas to you, bye, bye !!!