Recently, knife lovers have been especially popular with sharpening machines. On such a machine, you can sharpen the knife after maintaining the correct sharpening angle.

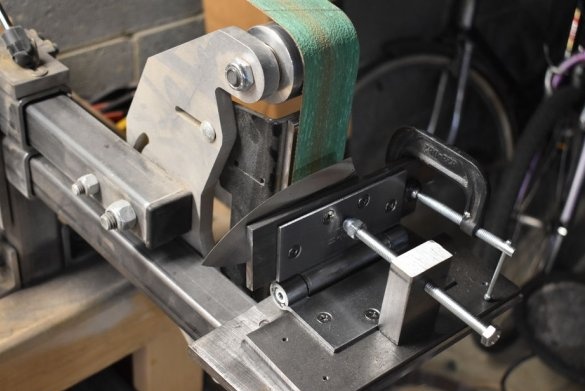

The master went a little different way. He has a belt grinder (grinder), and he decided to make device for sharpening with the right angle, knives on the grinder.

So, for the manufacture of devices you will need the following

Tools and materials:

-Bolt;

- Orgsteklo;

-Metal bar;

- The clamp is small;

-Bolt with wing head;

-Screws;

-USHM;

-Drilling machine;

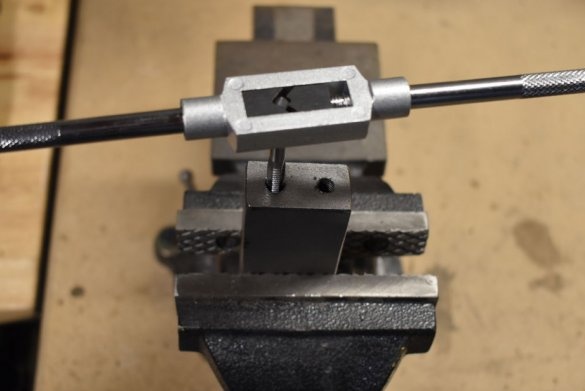

-Tap with holder;

-Tape grinding machine;

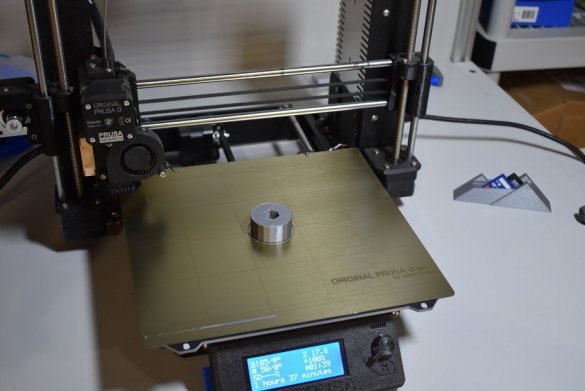

-3D printer (optional);

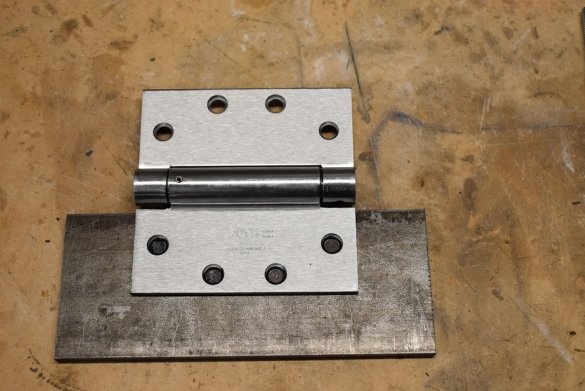

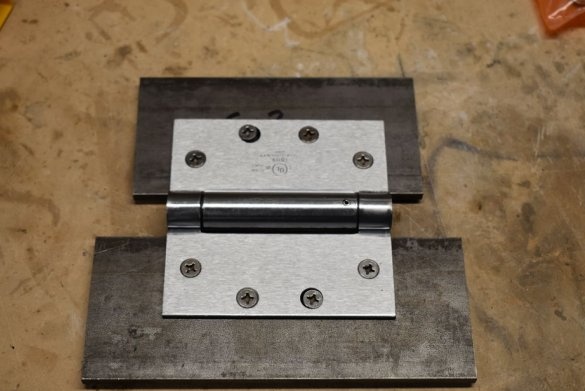

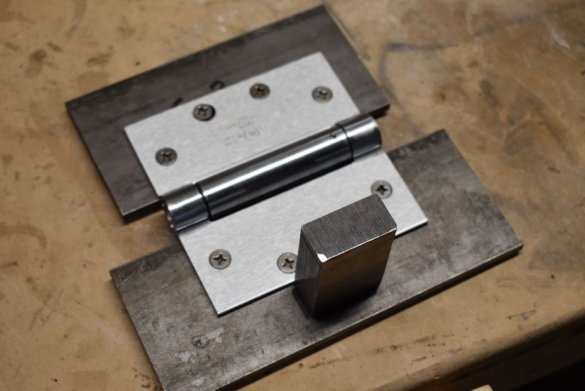

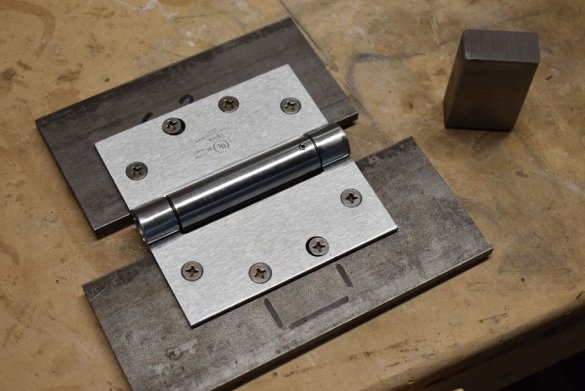

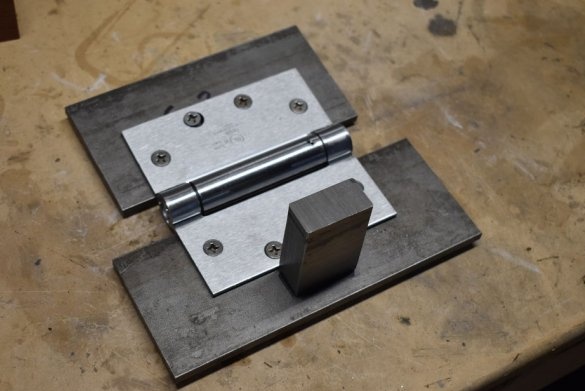

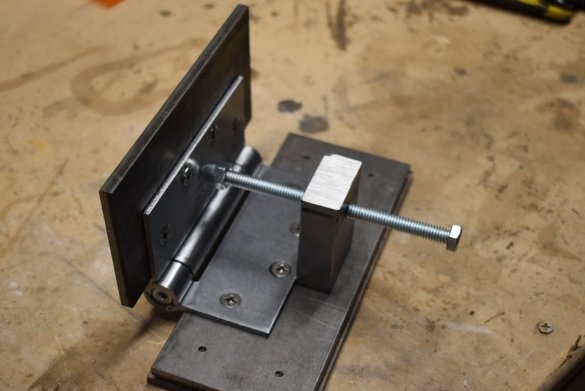

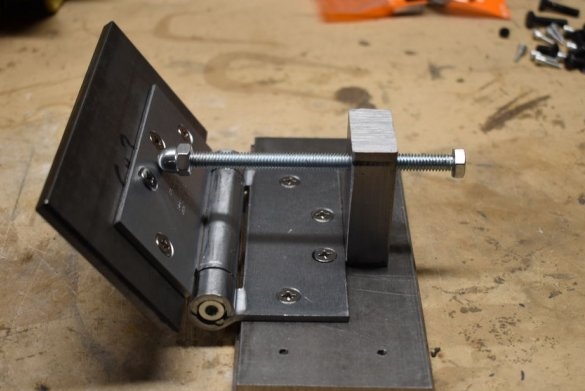

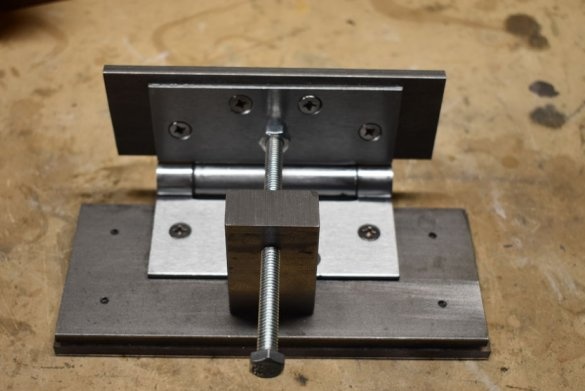

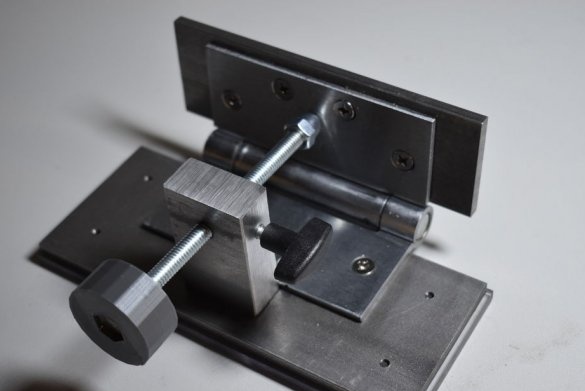

Step one: fasten the loop

Marks on the metal plates the place of attachment of the loop. Drill holes. Cuts the thread. Screws a loop to the plates. The larger plate is the base, the smaller is the movable part.

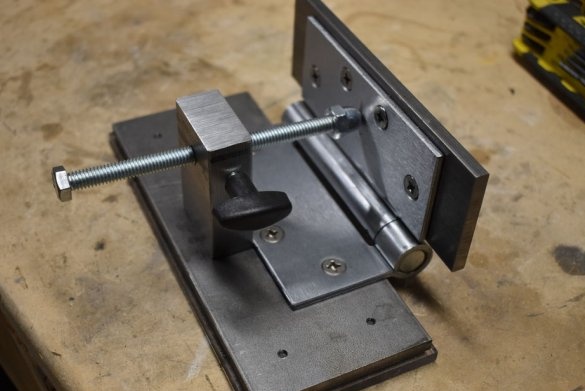

Step Two: Metal Bar

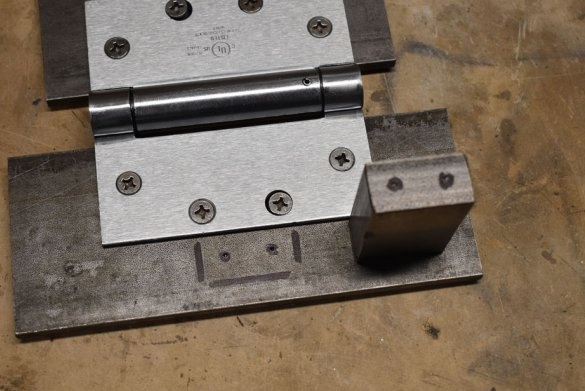

Drills coaxial holes in the base plate and in the end of the bar. It cuts the threads in the holes of the bar.

Another threaded hole makes in the bar for the thrust bolt.

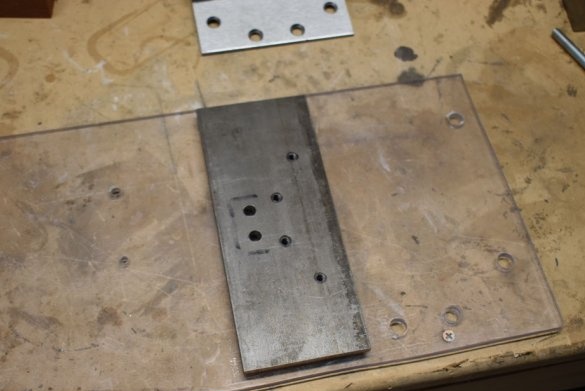

Step Three: Plexiglass

To reduce friction, from the bottom of the base plate, the master cuts and tightens plexiglass. Also, a plexiglass installed from below aligns the lower plane, masking the bolts of the bar (in plexiglass, drill holes for the bolt heads).

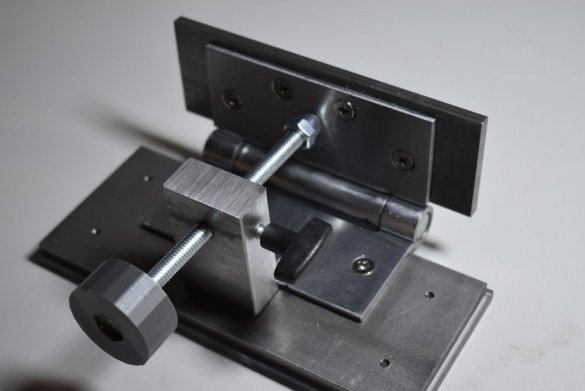

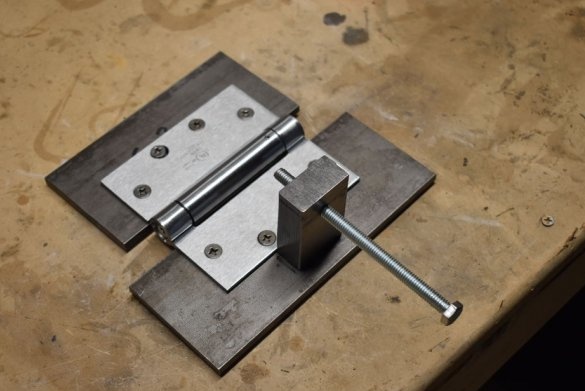

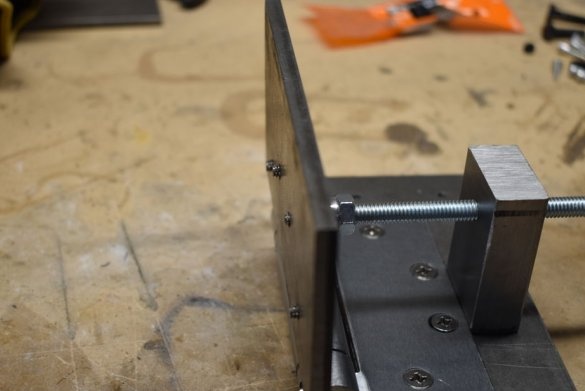

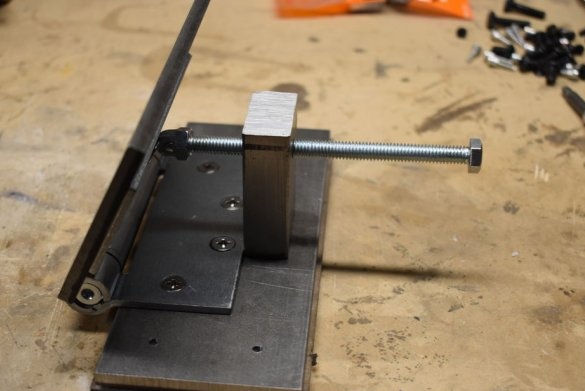

Step Four: Thrust Bolt

Now you need to screw the bolt into the metal block and, having set the loop half at 90 degrees, tighten the loop adjustment screw.

If necessary, you can set any desired angle.

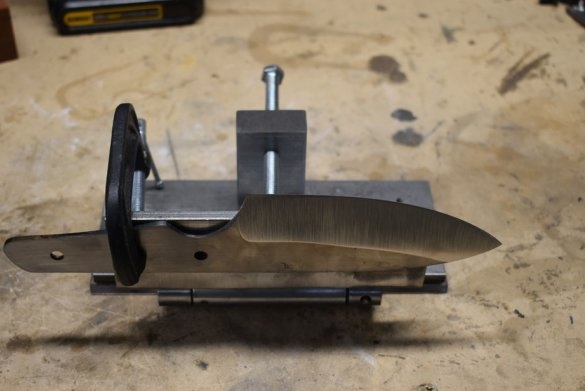

Step Five: Improvements

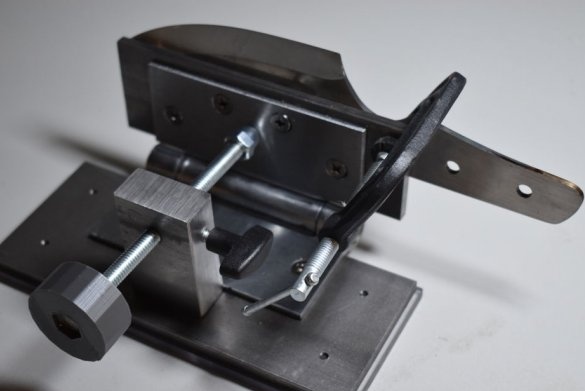

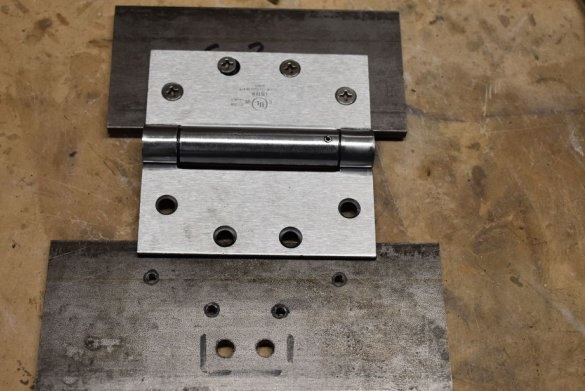

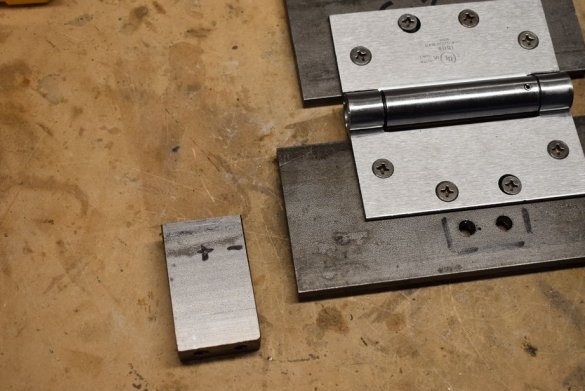

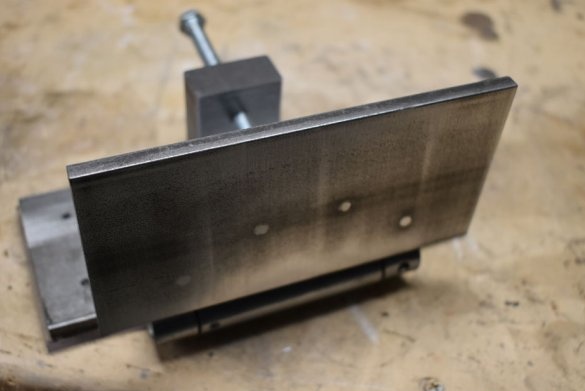

After checking the fixtures, a number of changes were made.

The movable plate was replaced with a smaller one.

A set screw is installed.

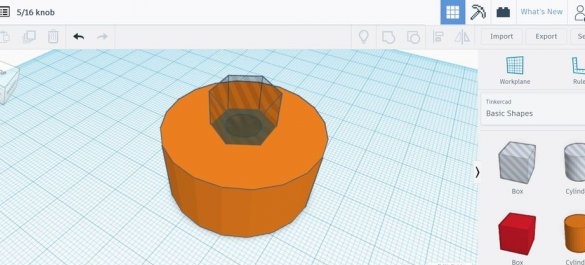

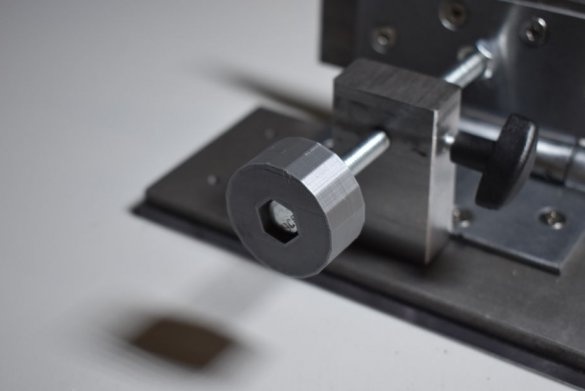

The handle on the stop screw is printed on a 3D printer.

All is ready. The knife is fixed on the plate with a clamp. The angle can be set using the protractor.