In this article, Alexander, YouTube author of the Alexander Polulyakh channel, will tell you how to make a safe stripper for wires of various diameters.

This home-made tool is extremely simple to manufacture, and you can make it in just a few minutes.

Materials

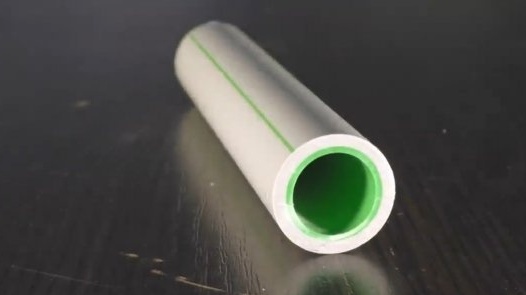

- PVC pipe

- Insulation tape

- The blade from the knife.

Instruments, used by the author.

- glue gun

- Screwdriver

- Drills of different diameters

- Vise.

Manufacturing process.

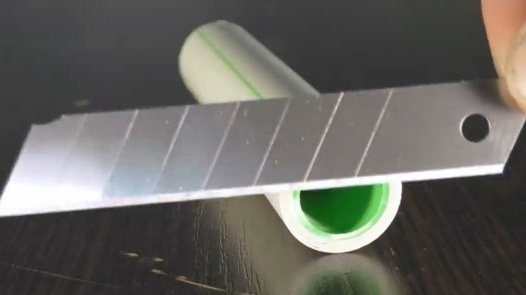

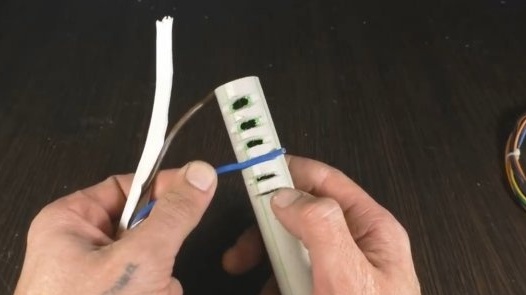

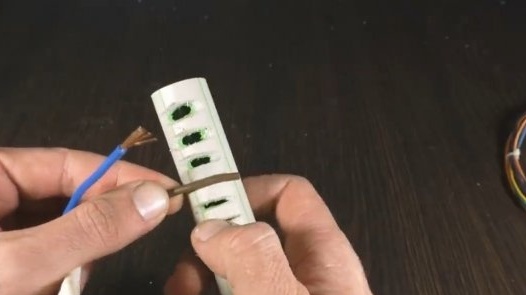

So, the author selected a scrap of tap, suitable in internal diameter to the width of the blade from the clerical knife. Then he applied several marks in increments of 1.5 cm.

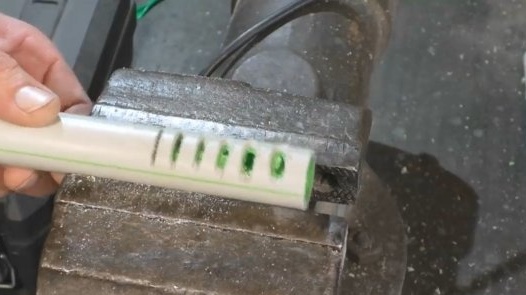

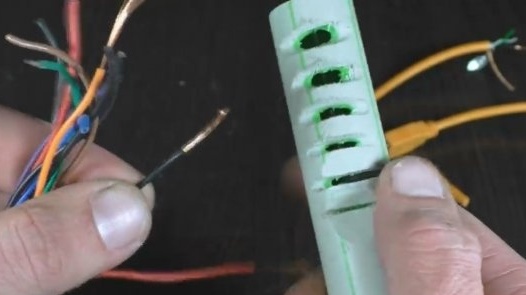

Then he fixed two tubes with each other using an insulating tape.

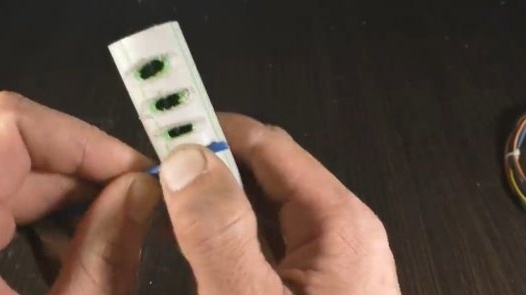

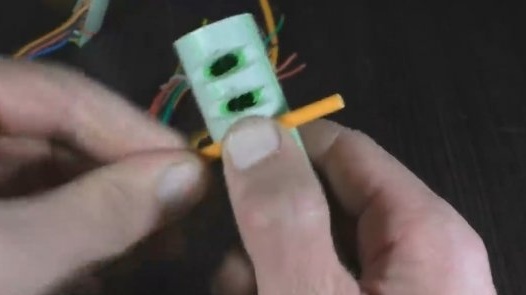

Now I just drilled holes at the pipe junction with drills of various diameters.

Under-drilled holes should be treated additionally and burrs must be cut with a knife.

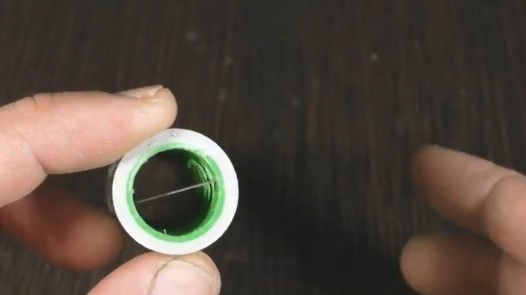

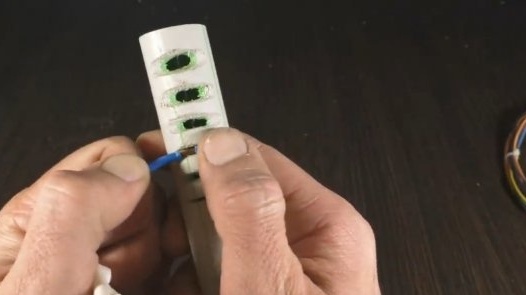

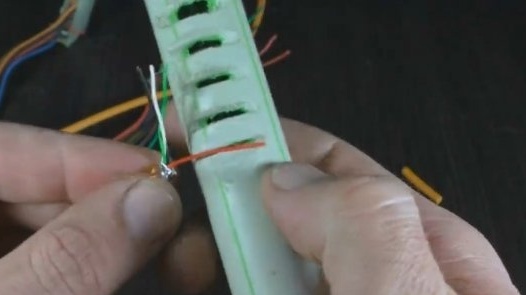

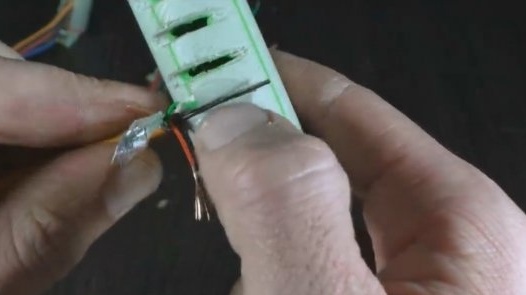

Then simply insert the blade from the knife into the tube so that it is centered on the holes. If the blade does not go loose, it can be additionally fixed with hot-melt adhesive, or second adhesive.

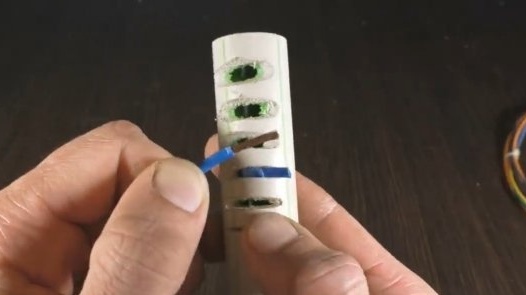

That's it, the tool is ready to go!

The blade is recessed in the holes, and it is very difficult to reach it with a finger.

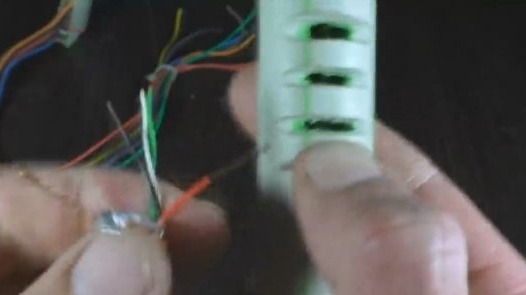

The tool copes with its task of stripping insulation perfectly. It is enough to insert the wire into the groove of a suitable diameter, and simply turn it. Then remove the insulation by pulling on the wire.

On an ordinary multicore copper wire of ШВВП the veins are not even damaged.

And now a multi-pair wire with a screen. Also without damage to small veins.

Even very thin wires can be used by such an instrument.

Thanks to the author for a simple but useful tool for home and work!

All good mood, good luck, and interesting ideas!