In this article, the author will tell us how to make custom exclusive handles for screwdrivers. Of course, the way to replace standard pens can be justified, for example, if you make a gift set. But sometimes the pens break and this article will be useful in this case too.

Tools and materials:

- Screwdrivers;

-Vise;

-Chisel;

-Hammer;

-Drill;

-Lathe;

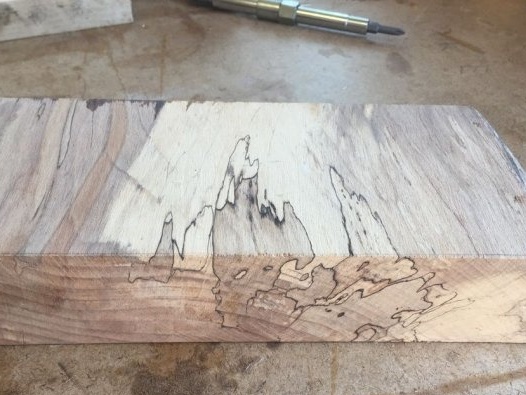

-Wooden blank;

-Pencil;

-Gon;

-Hacksaw;

-Copper tube;

Grinding machine;

-Sandpaper;

-Varnish;

- Stain;

-Burner;

Epoxy resin;

Step one: disassemble the screwdriver

If you have a broken screwdriver, then you can skip this step, if not, then look further. The author clamps the screwdriver in a vice and, using a chisel and a hammer, breaks the handle.

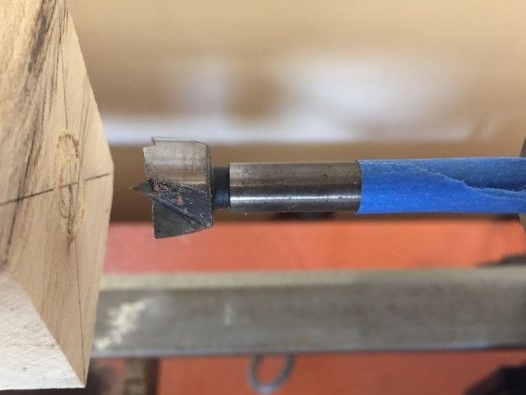

Step Two: Cap

The cap will protect the end of the handle from cracking. The master makes a cap from a copper tube. Cuts the tube and grinds.

Step Three: Handle Making

Sawing a board into bars. Sets the workpiece in a lathe and drills a blind hole in the center. Turns the workpiece, gives the desired shape.

Step Four: Finish and Build

After the handle is machined, the master polishes it with sandpaper and then with shavings. Installs a snap in the hole. Sets the cap. Further, the author writes about different ways of finishing the pen, it can be firing and subsequent varnish coating, and stain coating. You can coat the pens with acrylic paint, and then, on top, with epoxy.

These are the screwdrivers obtained from the master after assembly. Great gift set. Yes and in the garage a neighbor will find it easier to find his tool.