Hello everyone, if you like nuts, you just need to collect this homemade. This machine easily and simply cleans nuts from a strong shell, and homemade assembly is quite simple. No special tools for manufacturing are needed, here a drill is used, and the welding machine. All components are also easy to find. The machine is adjustable, it can be adjusted to the desired size of nuts. Whether it will crush walnuts and other large nuts is not known, but the machine crushes hazelnuts very easily and quickly. If the homemade product interests you, I suggest that you familiarize yourself with the project in more detail.

Materials and tools used by the author:

Material List:

- square profile pipe;

- steel round timber;

- a piece of steel plate;

- a bolt;

- steel plates.

Tool List:

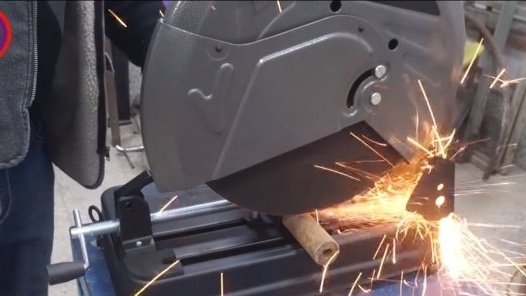

- Miter saw;

- ;

- drill;

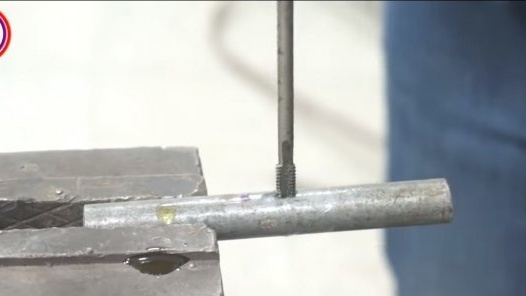

- tap for threading;

- ;

- marker and tape measure.

Homemade manufacturing process:

Step one. Housing

The case is very simple, we need a square profile pipe of suitable diameter. We cut it at an angle so that you can then weld the structure in the form of the letter “G”. For such purposes, the author uses a miter saw, but you can cope with the grinder, if you mark everything up first.

Step Two Knife

Next, we make a “knife” that will crush the nuts. The part is a roller with four blades. For the manufacture of the part, the author used a round log with a hole drilled through the center. Well, then everything is simple, we make the necessary calculations and cut out the part using a grinder.

Step Three Blade

Inside the device there is a blade, this is an emphasis that allows you to set the necessary clearance between the "knife". We make this part from strong sheet steel; we also need a steel rod, which the author used as an axis. We drill holes in the body, insert the axis and weld a plate to it.

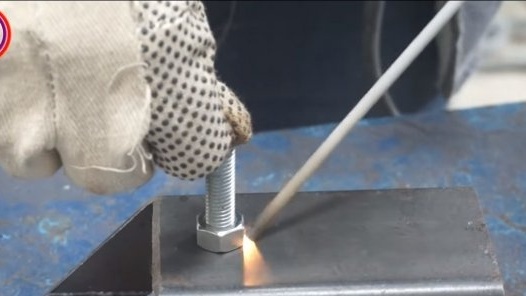

To adjust the angle of the plate, we weld a nut to the body and wrap the bolt, the further the bolt is wrapped, the smaller the gap between the stop and the knife.

Step Four Knife installation

We install a knife in the machine, for it you need to choose a strong axis, in the axis the author drilled a hole and cuts the thread for the fixing screw. We install the working body in the body and insert the axis, in the end it remains to tighten the fixing screw.

Step Five Legs and handle

We make legs for our machine, weld them from steel strips. We make the handle from round timber; profile pipes and other materials can also be used.

After that, the machine will be ready, you can test. The author easily peels hazelnuts with her, it turns out quite well. On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share with us your ideas and homemade products.