Hello everyone, I propose to consider the simplest frame for a chainsaw, with it you can turn a chainsaw into a small machine. It is convenient to cut boards, sticks and other similar objects on it. The main essence of the design is that here, when cutting a board or stick, the master automatically steps on the gas pedal and the chainsaw is gaining momentum. And when the cut is not made, the chainsaw runs at idle. If you slightly modernize the design, you can cut the boards at a given angle. Everything is assembled quite simply, the main material is profile pipes. If you are interested in the project, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- profile pipes;

- sheet metal;

- bolts and nuts;

- roundabout.

Tool List:

- ;

- ;

- spanners;

- Miter saw;

- marker, tape measure.

Machine manufacturing process:

Step one. The foundation

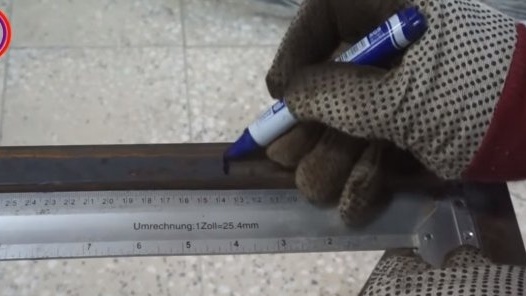

First of all, we will make the base, it looks like the frame of a table without a tabletop. We cut the blanks from the profile pipe, here it is most convenient to have a miter saw, but you can also work with a grinder. Well, then we weld the rectangle, the author chose its dimensions in accordance with the length of his saw. We weld the legs to the resulting rectangle, we clean the welds with a grinder so that everything looks neat.

Step Two Installation of the grinder

The grinder needs to be fixed securely, first we fix the grinder to the tire. To do this, we weld a piece of pipe to the table frame, and we weld a vertical rack from a profile pipe to it. We drill a hole in the stand and the tire of the chainsaw, if it is not there, that's all, now we fasten the tire to the rack with a bolt and nut.

In the back we fasten the chainsaw by the handle, for this we weld plates on the sides of the handle to the frame so that the handle could not move to the side. Then we drill two holes and press the handle with a steel plate to the frame using two bolts with nuts. To reduce the load on the place where the tire is attached to the chainsaw, we weld another piece of the profile pipe under the saw so that the saw rests on three supports.

Step ThreePush mechanism

We make the push mechanism, thanks to which we will make the trigger of the chainsaw. We will need two long levers pivotally connected, for this purpose the author used steel strips. As hinges, bolts with nuts were used. The direct pressure lever is made of round timber; it is pivotally mounted on the frame using welded ears made of sheet steel. When the board presses the lever, the pressure lever moves to the rear, thereby pushing the trigger and including high speeds of the chainsaw.

After that, the machine is ready, start a chainsaw and get to work. Work has become simple and safe. So it’s very easy to cut sticks, you don’t need to hold a heavy chainsaw in your hands, which we quickly got tired of earlier. You can also quickly and conveniently cut boards, it is especially convenient for household purposes when you need to craft something, for example, houses for rabbits and so on. Homemade ready, I hope the project was useful to you. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!