In his article, the author presents for our review several devices for a carpentry workshop. All these fixtures he printed on a 3D printer and each has an attached file for printing. Of course, in our country, 3D printing is not so common, but in many cities such a service exists. And in the absence of access to a 3D printer, all these products can be made of other materials manually.

So, let's look at the master’s products.

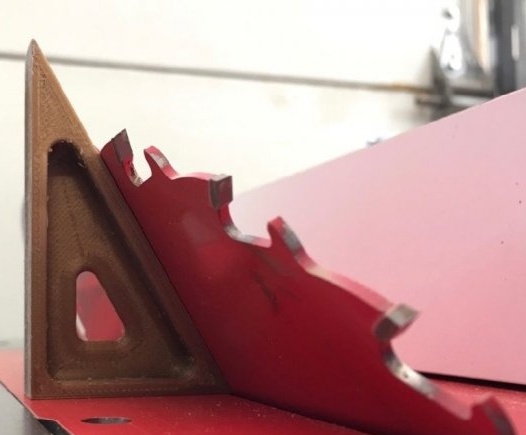

Corner clamp.

These staples are designed to connect the corners of frames, for example, paintings or boxes. The connection angle is not more than 45 degrees. To avoid slipping, sandpaper is glued onto the inner plane.

File to download.

Pens.

Pens can be used for various purposes. The master introduced the pens in two sizes.

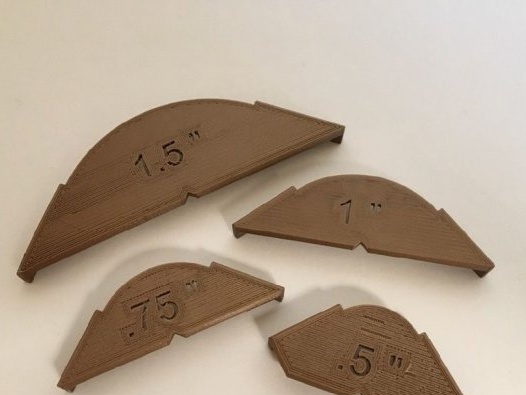

Patterns for rounded corners.

Using these templates, you can evenly round the corners of the product.

Patterns are available in four sizes.

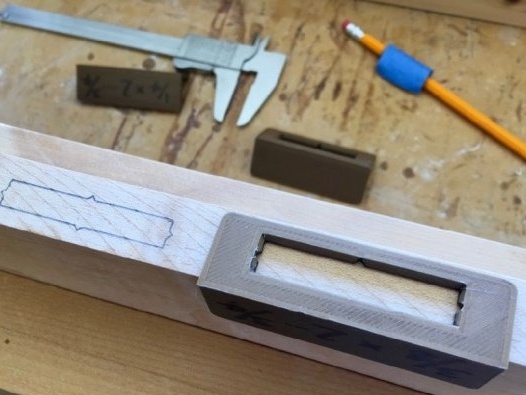

Templates for frame.

Templates are designed to facilitate the work of selecting material, under the cutter, or chisel.

Templates have three sizes.

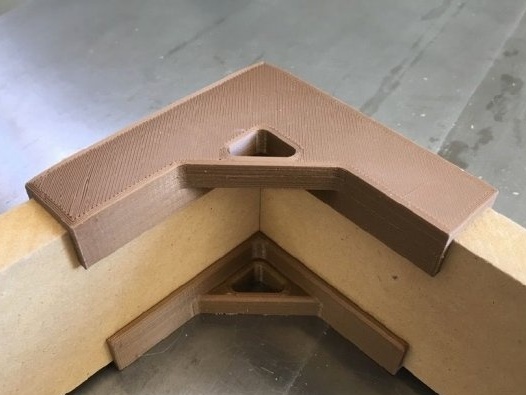

Corner patterns.

Such patterns make assembly easier.

The square.

Classic square to determine the angle of 30, 60, 90 degrees.

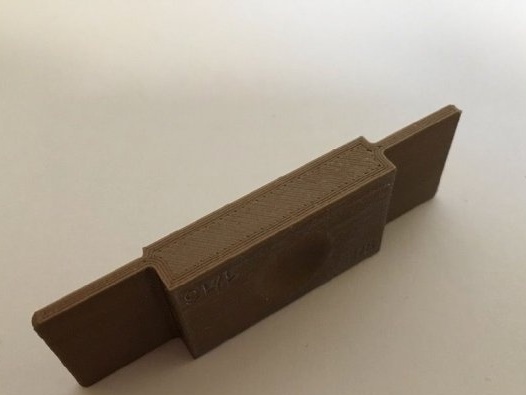

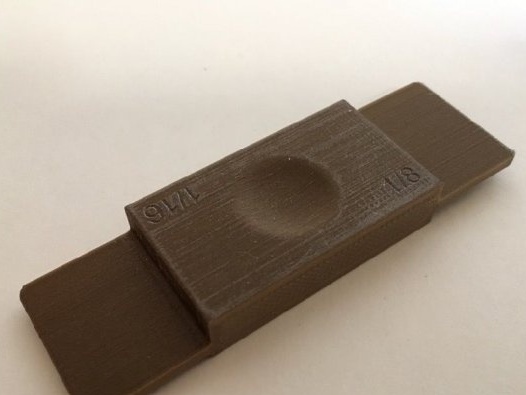

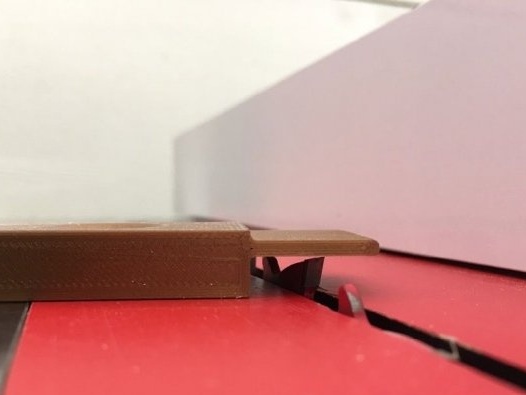

Saw blade height setting pattern.

Using the template, you can set the reach of the circular saw blade to 1/16 ", 1/8", 3/16 "and 1/4".

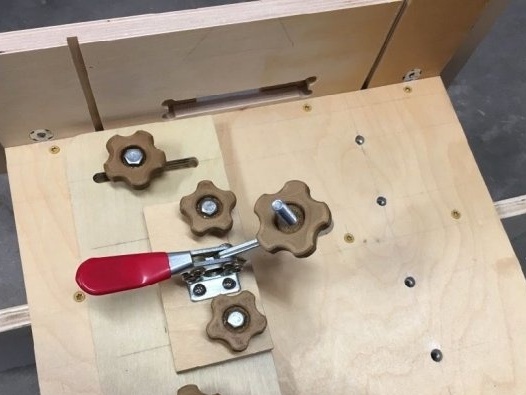

Guides.

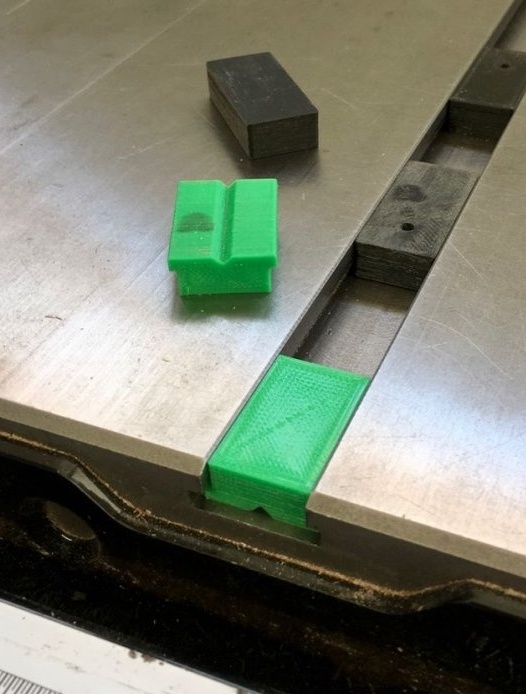

This device is designed for installation along the guides of the desktop and fastening to them various additional tools.

Insert.

The insert is intended for a band saw.

Clamps.

These products are used in conjunction with Magswitch magnetic clamps (MAGJIG 95).

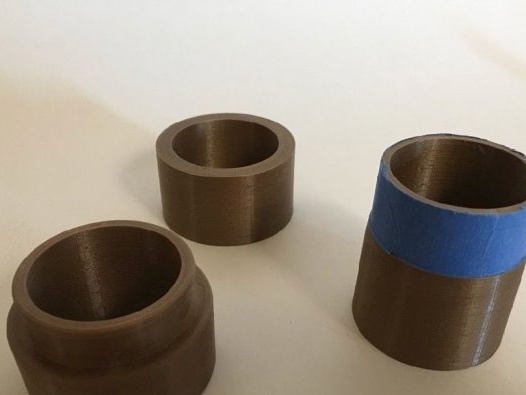

Adapters

Using adapters, you can connect a variety of tools to the vacuum cleaner.

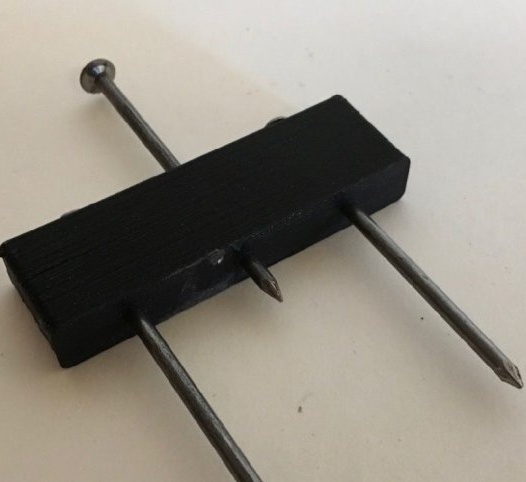

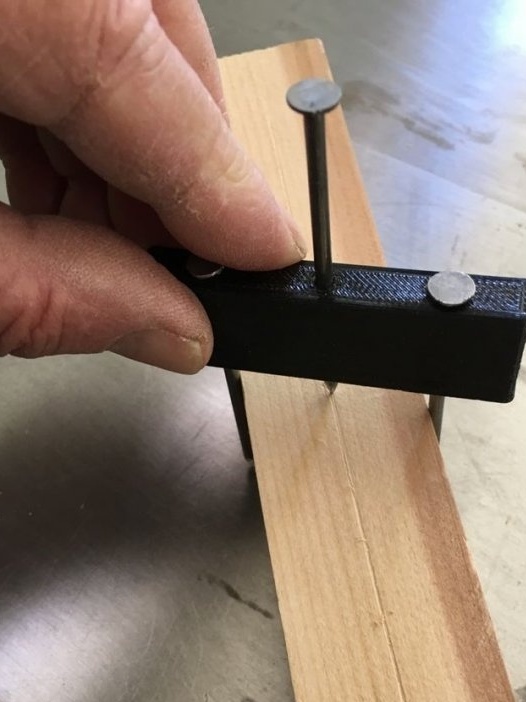

Centering.

With the help of the last device, you can easily find the center line of the bar, rail, corner.

That's all. Of course, some of these devices need to be adapted to their needs, with their sizes, but the main thing is to show the idea.